Membrane-free ion exchange resin electric regeneration device based on filter element electrode

An ion exchange resin and electric regeneration technology, which is applied in the direction of electric regeneration, can solve problems such as crowded regenerated concentrated water pipeline layout, affecting system operation performance, and complicated electrode wiring, so as to inhibit cathode scaling, solve hydraulic bias flow, and avoid hydraulic The effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

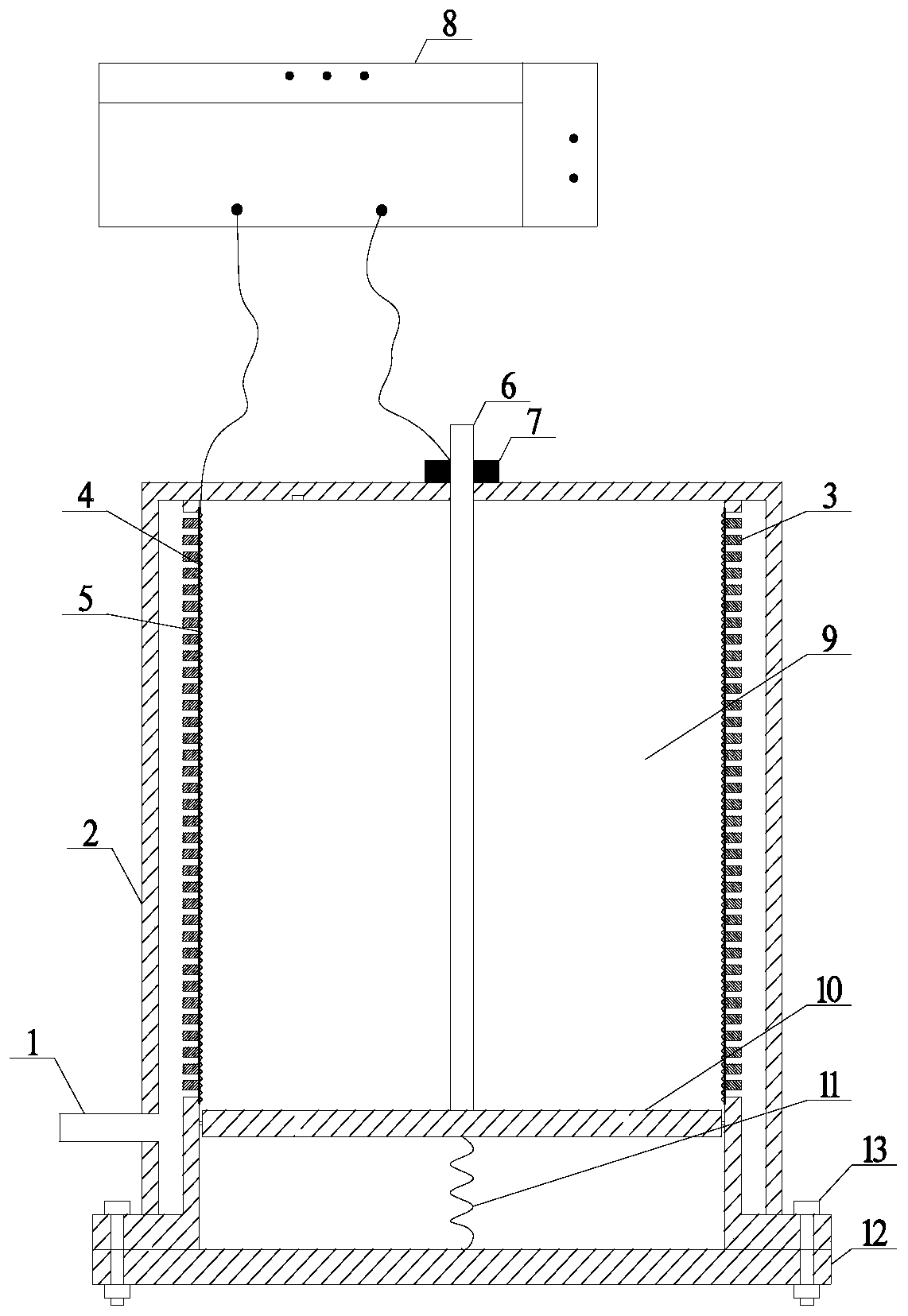

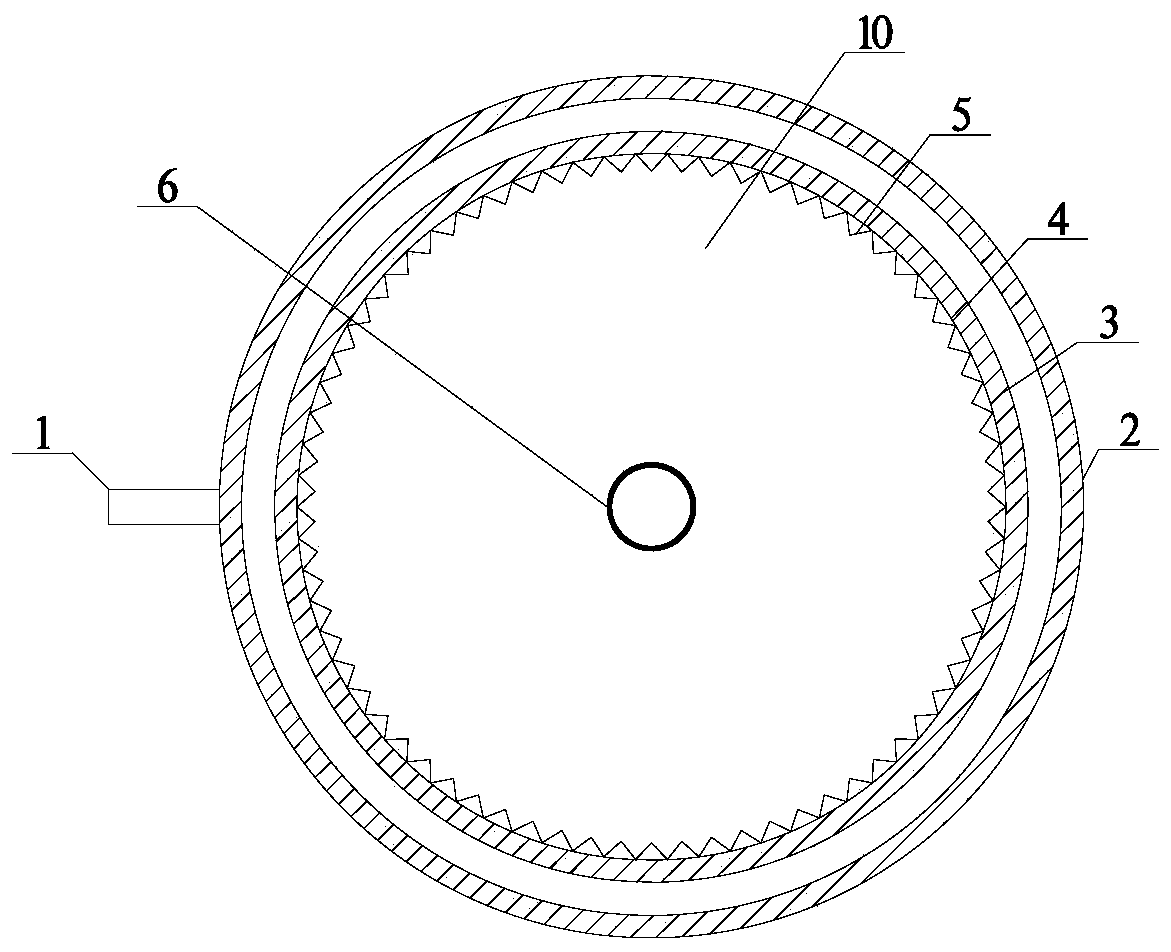

[0032] 8.6L of 001×7 styrene-based strongly acidic cation-exchange resin and 201×7 styrene-based strongly basic anion-exchange resin that were deactivated by NaCl, the mixing ratio of anion and cation resins is 2:1, using figure 1The shown membraneless ion exchange resin electrical regeneration device based on the cartridge electrode performs regeneration treatment. The main parameters of the device are as follows: shell height 20cm, inner diameter 35cm, support layer inner diameter 30cm, filter cloth aperture 0.05mm, mesh cathode aperture 0.5mm, filter anode aperture 50μm, resin layer height 10cm. The regeneration operating conditions are as follows: regeneration voltage 190V, regeneration current 4.0A ~ 8.0A, pure water flow rate 600.0L / h, regeneration time 2.0h. The resin regeneration effect is as follows: the exchange capacity of the cation exchange resin is 3.5 (dry) mmol / g, and the exchange capacity of the anion exchange resin is 2.0 (dry) mmol / g, both of which reach the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com