PCBA washing tooling and washing method

A tooling and washing technology, applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of the whole machine imaging particles being dirty, unable to be washed with water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to describe in detail the structure of the PCBA washing tool provided by the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

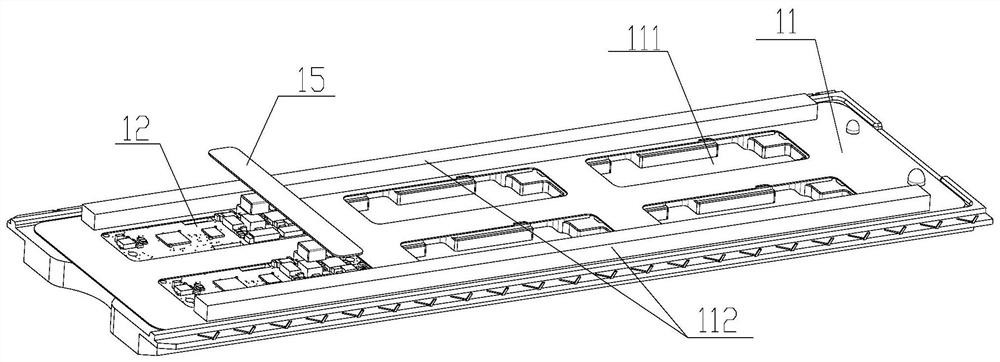

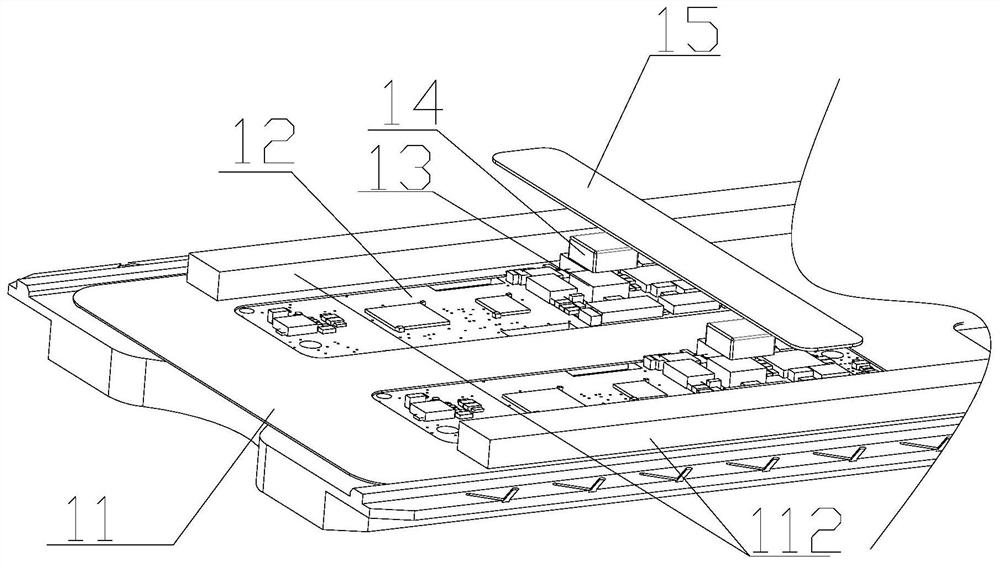

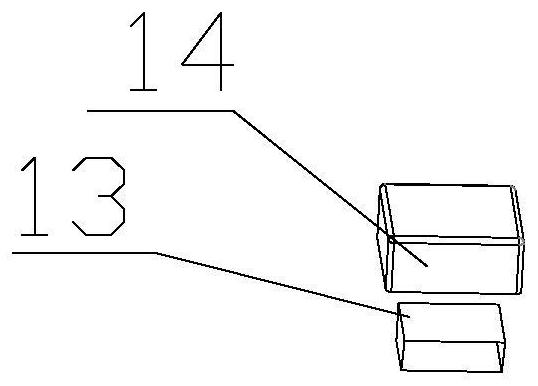

[0038] figure 1 Shows the front view structure of the PCBA washing tooling according to the embodiment of the present invention, figure 2 Shows the partially enlarged structure of the PCBA 12 water washing tooling according to the embodiment of the present invention, image 3 The enlarged structure of the device to be waterproofed 13 and the waterproof rubber sleeve 14 according to the embodiment of the present invention is shown.

[0039] combine Figure 1 to Figure 3 Commonly shown, the PCBA12 washing tooling provided by the present invention includes: a preset washing carrier 11 and a PCBA12 loaded on the washing carrier 11; it should be noted that there are two interpretations of PCBA12 in the industry , one refers to the process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com