Porous film getter structure and preparation method thereof

A porous film and porous structure technology, applied in the field of high vacuum MEMS device packaging, can solve the problems of weak three-dimensional structure, weak adhesion of film getters and sidewalls, contamination of devices, etc., to maintain vacuum and use Extended life, increased suction performance and service life, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

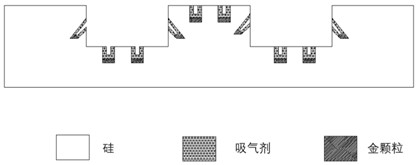

[0054] A porous thin film getter structure such as figure 1 As shown, including the wafer and the film getter, the upper surface of the wafer has a plurality of groove structures, the inner walls of the groove structures are all porous structures, and the wafer surface connecting adjacent groove structures is also A porous structure, the porous structure is provided with a thin film getter, and the thin film getter covers the porous structure.

[0055] Gold particles are arranged on the pore bottom of the porous structure, and the thin film getter covers the gold particles. The particle diameter of the gold particles is between tens of nanometers and several micrometers, which can be adjusted according to the required structural size of the thin film getter.

[0056] The cross section of the groove structure is " "shape.

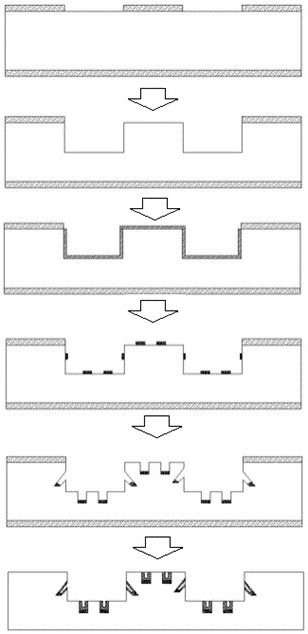

[0057] The above-mentioned porous thin film getter structure, that is, the production of the capped silicon wafer, the specific preparation process diag...

Embodiment 2

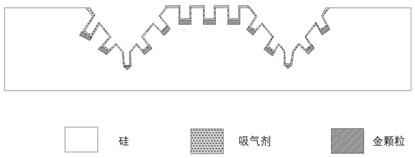

[0072] A porous thin film getter structure such as image 3 As shown, it includes a wafer and a film getter, the upper surface of the wafer has a groove structure, the inner wall of the groove structure is a porous structure, the porous structure is provided with a film getter, and the A thin film getter covers the porous structure.

[0073] Gold particles are arranged on the pore bottom of the porous structure, and the thin film getter covers the gold particles. The particle size of the gold particles is tens of nanometers to several micrometers; the cross section of the groove structure is V-shaped.

[0074] The wafer is provided with more than two groove structures, and the surface of the wafer connecting adjacent groove structures is a porous structure, and a thin film getter is provided on the porous structure, and the thin film getter covers the the porous structure.

[0075] The above-mentioned porous thin film getter structure, that is, the production of the capped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com