Auxiliary bone sawing device for meat processing

A technology of meat processing and bone sawing, which is applied in the direction of meat processing equipment, processed meat, applications, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effects of fast cutting speed, improved efficiency, and convenient refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

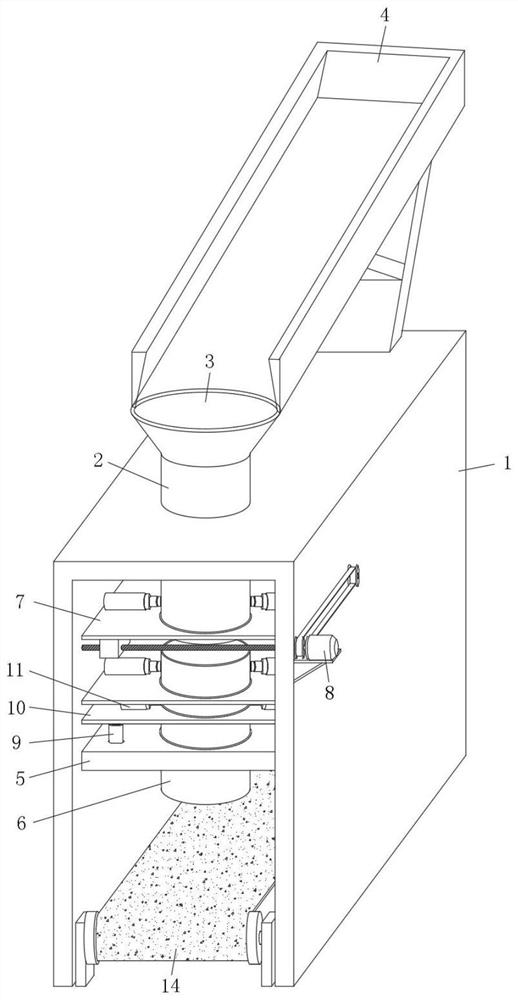

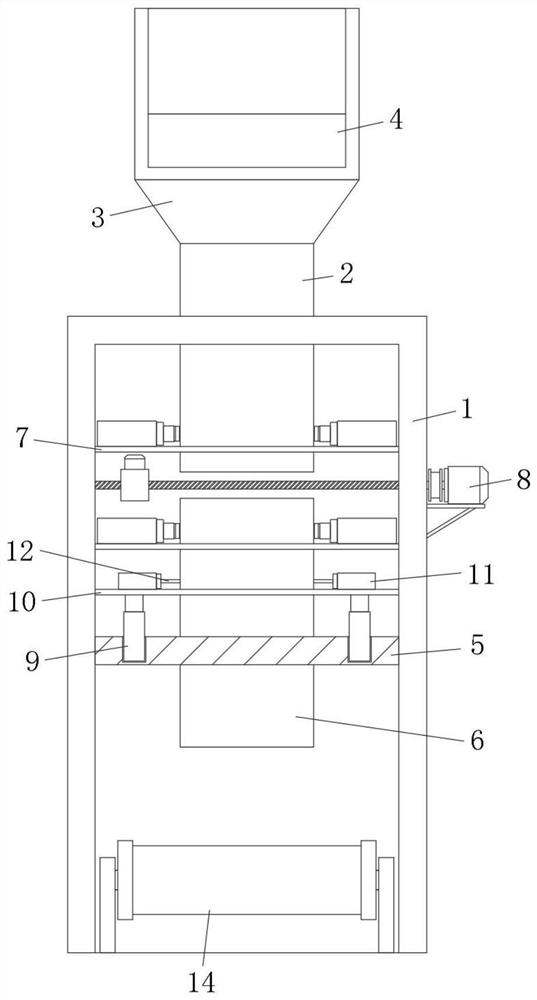

[0032] refer to figure 1 and 2 , an auxiliary bone sawing device for meat processing, comprising a working frame 1, characterized in that the top surface of the working frame 1 is provided with a mounting hole 1, and the inner wall of the mounting hole 1 is fixed with an upper slitting pipe 2, and the upper slitting pipe 2 The top is fixed with a feeding hopper 3, and the rear side of the feeding hopper 3 is connected with a feeding tray 4 for feeding meat bones. The feeding tray 4 is fixed on the top surface of the working frame 1 through a bracket, and the inner wall of the front middle part of the working frame 1 is fixed with a mounting plate 5. The top surface of the mounting plate 5 runs through and is provided with mounting holes 2, the inner wall of the mounting holes 2 is fixed with the lower slitting pipe 6, the lower side of the upper slitting pipe 2 and the upper side of the lower slitting pipe 6 are equipped with a bone fixing mechanism 7, and the upper slitting ...

Embodiment 2

[0034] Such as image 3 and 4As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bone fixation mechanism 7 includes a horizontal plate 71, and the horizontal plate 71 is sleeved on the outside of the upper slitting tube 2 and the lower slitting tube 6 and fixed on the inner wall of the working frame 1 On both sides of the top surface of the horizontal plate 71, electric telescopic rod two 72 are fixed, and the output end of the electric telescopic rod two 72 is fixed with a limit assembly 73, and the lower side of the upper splitting pipe 2 and the upper side of the lower splitting pipe 6 are provided with fixed groove, and the limit assembly 73 is all slidably connected in the fixed groove, the limit assembly 73 includes a mounting cylinder 731, the inner wall of the mounting cylinder 731 is slidably connected with a fixing column 732, and an elastic member is fixed between the fixing column 732 and the bottom surface of the mounting cylinder 731,...

Embodiment 3

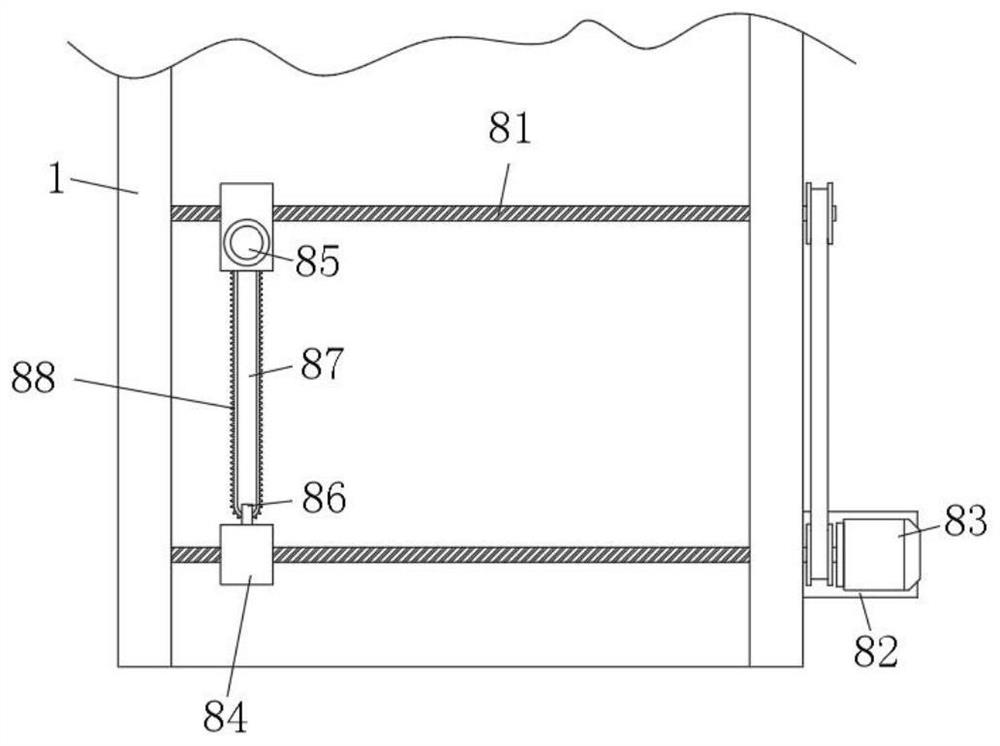

[0037] Such as figure 1 and 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bone sawing mechanism 8 includes a screw rod 81, two screw rods 81 are provided and symmetrically distributed on the front and rear sides of the upper slitting tube 2, and one end of the two screw rods 81 It extends to the outside of the working frame 1 and is rotationally connected by a synchronous conveying chain. A horizontal frame 82 is also fixed on one side of the working frame 1. The top surface of the horizontal frame 82 is fixed with a servo motor 83 through screws. The output end of the servo motor 83 is connected to one of the wires. Rod 81 is fixedly connected, and the outer wall of screw mandrel 81 is threadedly connected with mounting sleeve 84, and cutting motor 85 is installed on the top surface of rear side mounting sleeve 84, and U-shaped plate 86 is also fixed on the rear end surface of front side mounting sleeve 84, and U-shaped plate 86 and A cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com