Blade tenon magnetic powder detection device

A technology of magnetic particle detection and blade tenon, which is applied in the direction of material magnetic variable, can solve the problems of poor detection effect, achieve the effect of improving detection efficiency, prolonging the magnetization length, and speeding up detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

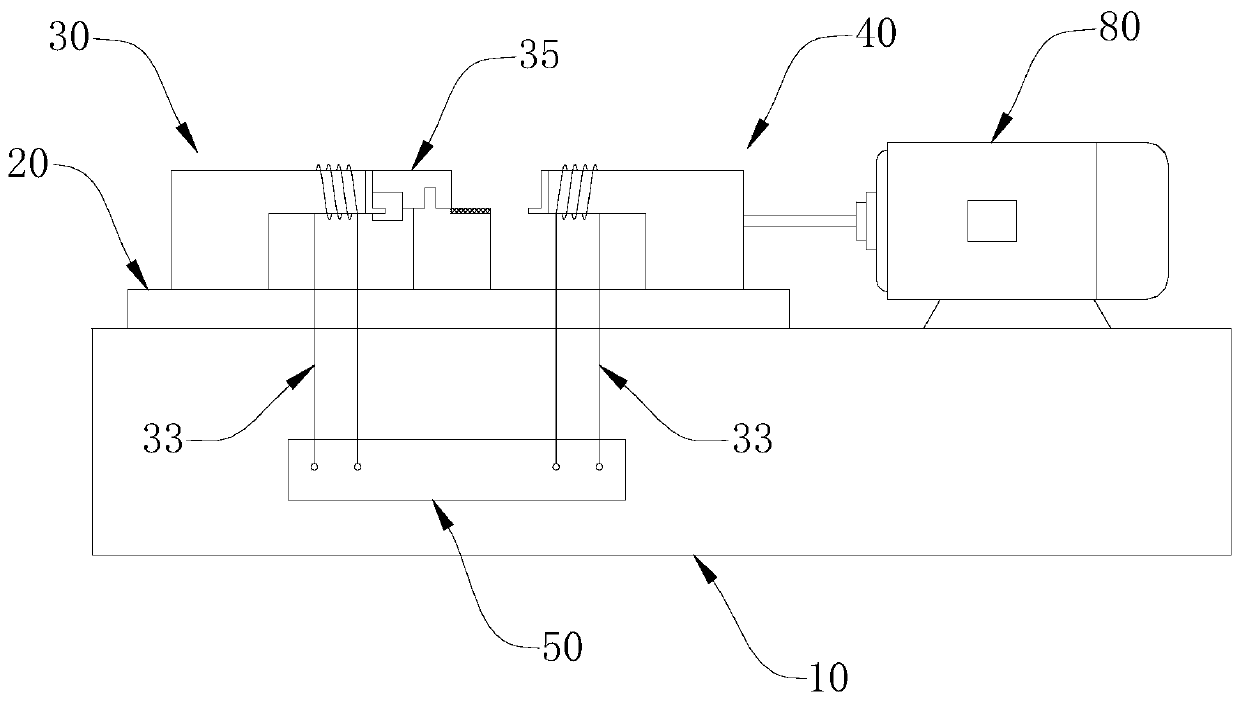

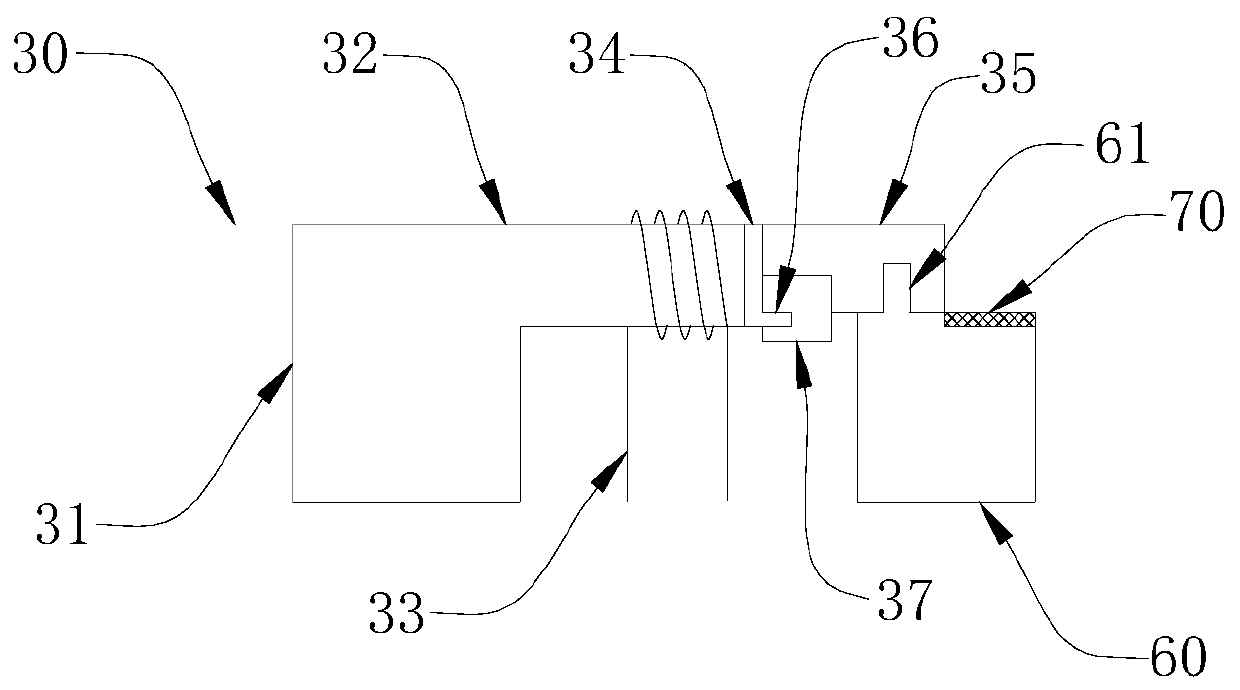

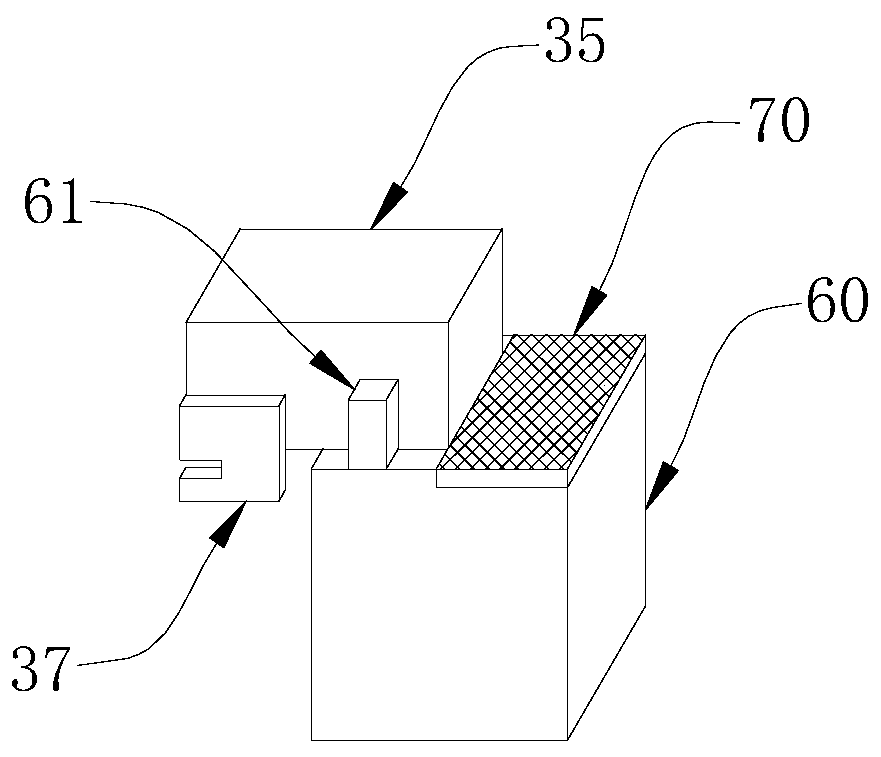

[0041] Please refer to figure 1 , a blade tenon magnetic powder testing device, comprising: a testing table 10 , a first magnetic core 20 , a second magnetic core 30 , a third magnetic core 40 and a magnetization power supply 50 . The first magnetic core 20 is located on the detection platform 10 , and the second magnetic core 30 and the third magnetic core 40 are both located on the first magnetic core 20 . The second magnetic core 30 and the third magnetic core 40 are arranged at intervals, the second magnetic core 30 is connected with an extension block 35, the extension block 35 is located between the second magnetic core 30 and the third magnetic core 40, and the extension block 35 is connected to the third magnetic core 40. There is a gap between the magnetic cores 40 for placing the blade tenon 90 . The second magnetic core 30 and the third magnetic core 40 are respectively wound with a coil 33 , and both ends of the coil 33 are respectively electrically connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com