Method for cultivating high-quality winter wheat by use of biogas liquid

A technology of winter wheat and biogas slurry is applied in the field of high-yield and high-quality winter wheat cultivation using biogas slurry, which can solve problems such as pesticide residues and nitrogen fertilizer pollution, and achieve the effects of reducing insect pests, inhibiting disease occurrence, and reducing input amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

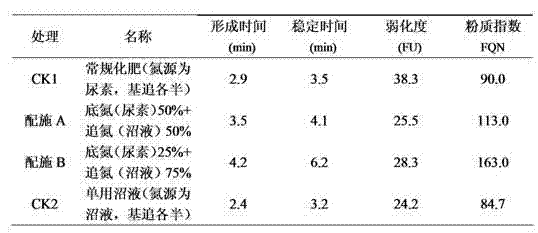

[0020] Example 1 The experiment was carried out in Zhaobao Town, Wen County, Henan Province in 2007-2008, with random block design, 3 repetitions, and the area of the plot was 3 m×7 m. Wheat variety Rumai 0319 was selected as the test material. The soil texture of the test field is medium loam, and the organic matter content of the 0-20 cm plow layer is 10.8 g kg -1 , total nitrogen 1.4 g·kg -1 , Alkaline hydrolyzed nitrogen 98.7 mg·kg -1 , available phosphorus 58.2 mg·kg -1 , available potassium 86.5 mg·kg -1 , pH 7.5. The biogas slurry is taken from the biogas digesters normally used by farmers. The raw materials are mainly pig manure and urine. After fermentation for more than 3 months, it is fine, uniform, transparent and has no obvious fecal odor. The total nitrogen content in the biogas slurry is 0.14%. The total amount of nitrogen applied during the wheat growth period is 16 kg / 667m of pure nitrogen 2 10 days before sowing, the base application of biogas fertil...

Embodiment 2

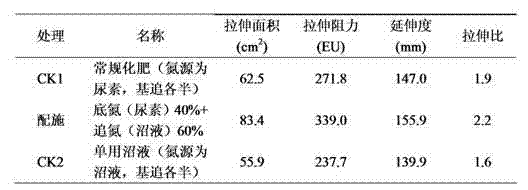

[0041] Example 2 The experiment was carried out in Zhaobao Town, Wen County, Henan Province from 2008 to 2009, with a randomized block design, 3 repetitions, and a plot area of 3 m×7 m. Wheat variety Wenmai 28 was selected as the test material. The soil texture of the test field is medium loam, and the organic matter content of the 0-20 cm plow layer is 12.5 g kg -1 , total nitrogen 1.5 g·kg -1 , Alkaline hydrolyzed nitrogen 111.2 mg·kg -1 , available phosphorus 64.3 mg·kg -1 , available potassium 73.6 mg·kg -1 , pH 7.5. The biogas slurry is taken from the biogas digesters normally used by farmers. The raw materials are mainly human and livestock excrement and urine. After fermentation for more than 3 months, it is fine and uniform, transparent and has no obvious fecal odor. The total nitrogen content in the biogas slurry is 0.12%; The amount of nitrogen is pure nitrogen 18 kg / 667m 2 10 days before sowing, the base application of biogas fertilizer combined with botto...

Embodiment 3

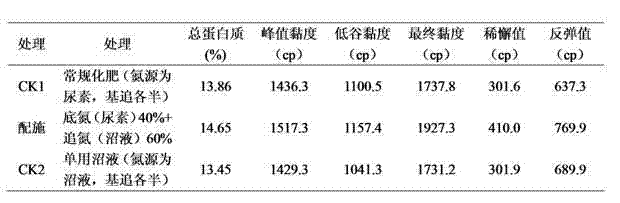

[0061] Example 3 The experiment was carried out in Qugou Town, Anyang County, Henan Province from 2009 to 2010. The randomized block design was repeated 3 times, and the area of the plot was 4.4 m×5 m. Wheat variety Zhengmai 366 was selected as the test material. The organic matter content of the 0-20 cm plow layer in the test field is 15.2 g·kg -1 , total nitrogen 1.7 g·kg -1 , Alkaline hydrolyzed nitrogen 122.7 mg·kg -1 , available phosphorus 52.1 mg·kg -1 , available potassium 104.6 mg·kg -1 , pH 7.5. The biogas slurry is taken from the biogas digesters normally used by farmers. The raw materials are mainly pig manure and urine. After fermentation for more than 3 months, it is fine, uniform, transparent and has no obvious fecal odor. The total nitrogen content in the biogas slurry is 0.20%. The total amount of nitrogen applied during the wheat growth period is 15 kg / 667m of pure nitrogen 2 10 days before sowing, the base application of biogas fertilizer combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com