Tube bundle sleeving method of two folding coiled tube high-pressure heater

A technology of high-pressure heaters and serpentine tubes, applied in the direction of fixed tubular conduit components, heat exchanger types, heat exchanger shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

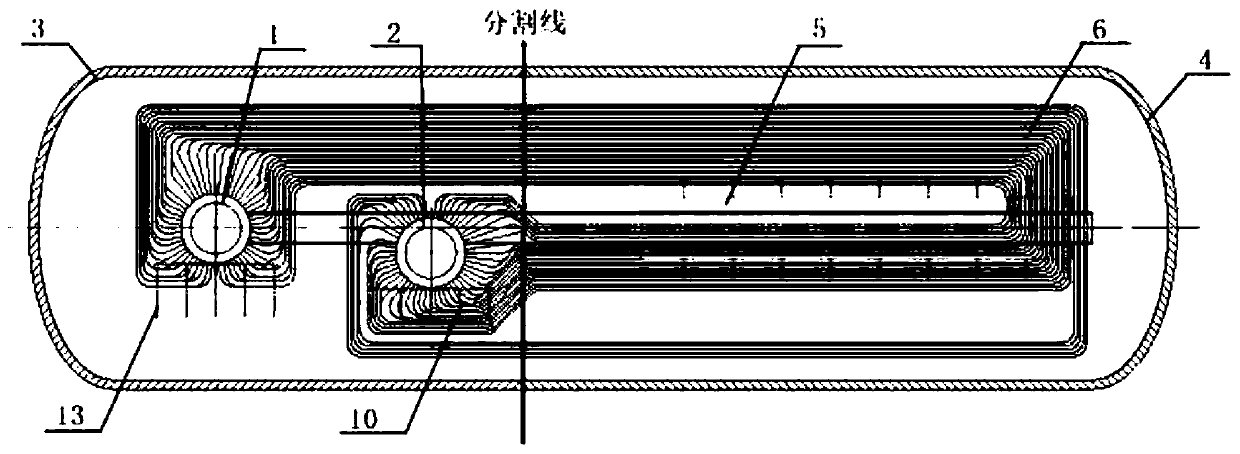

[0026] Such as figure 1 As shown, since the shell of the two-fold serpentine tube high-pressure heater is welded with pre-welded parts such as angle steel and steel plate, and the side of the header is welded with cladding and other parts, if the conventional heat exchanger is used in the package method, The tube bundle and header will interfere with the angle steel, steel plate, etc. inside the shell, and it is impossible to realize the package. Therefore, the applicant needs to design a process that can be used for the tube bundle package of the two-fold serpentine tube header-type high-pressure heater.

[0027] In order to solve the above technical problems, the present invention proposes a tube bundle fitting method for a two-fold serpentine tube high-pressure heater, which specifically includes the following steps:

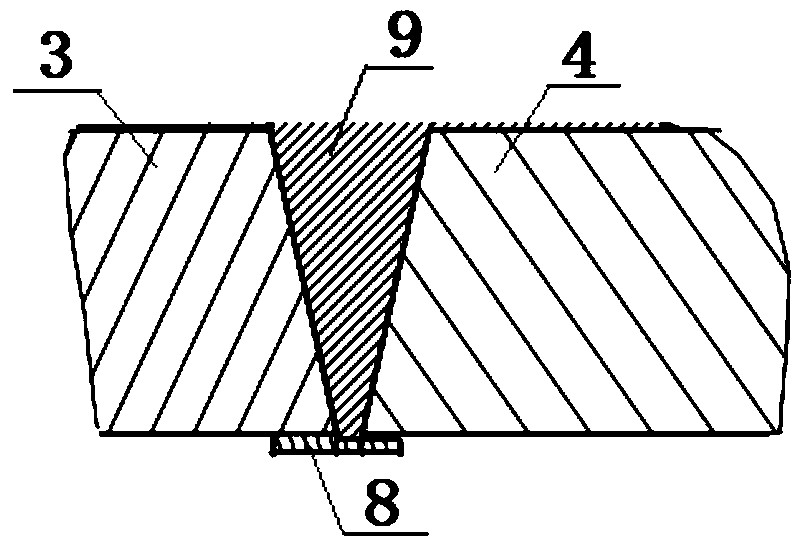

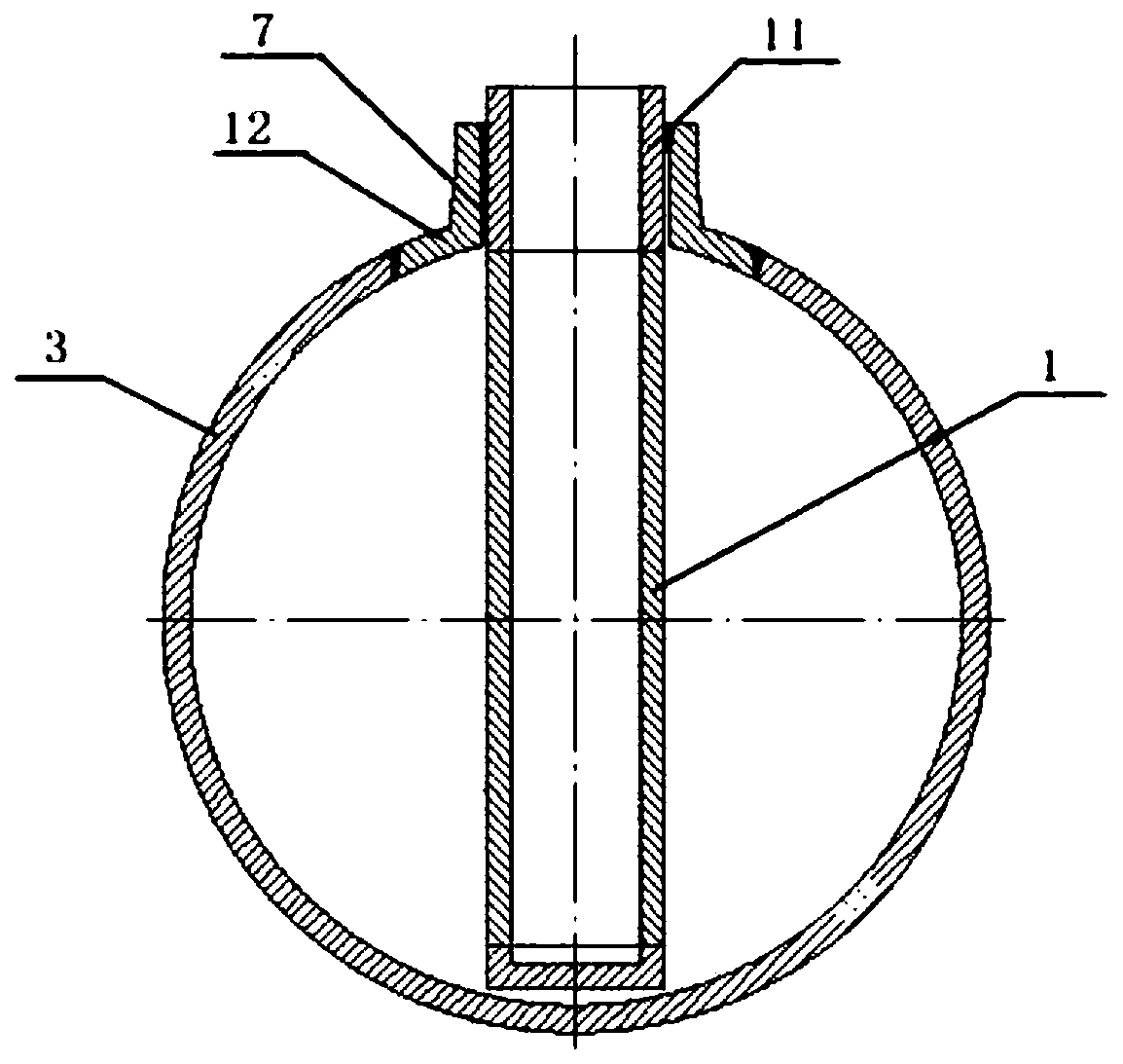

[0028] S1: Divide the shell of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com