An indexable clamp with adjustable eccentricity on the indexing chuck

An indexing chuck and eccentricity technology, applied in manufacturing tools, precision positioning equipment, metal processing equipment, etc., can solve the problems of cumbersome clamping and positioning, poor consistency of parts, etc., to reduce the number of fixtures, simple structure, and reduce ordering. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0022] In the prior art, the sag of the pressed profile is usually formed on a press using a sag die. This type of mold mainly includes an upper mold, a lower left mold, a lower right mold, a backing plate, a guide plate, an upper template, a lower template, etc. The mold structure is complex, and it is impossible to effectively clamp the 3 web of the part.

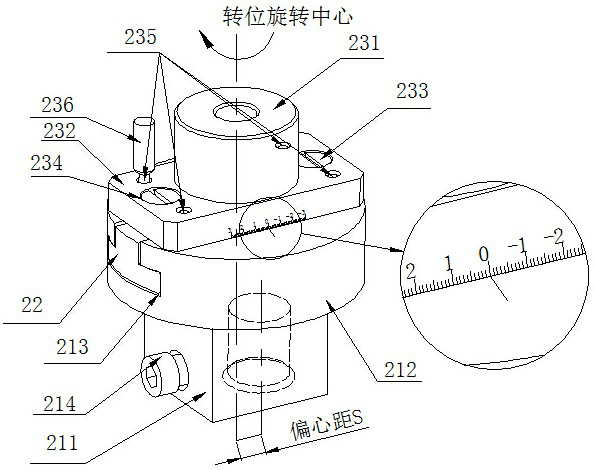

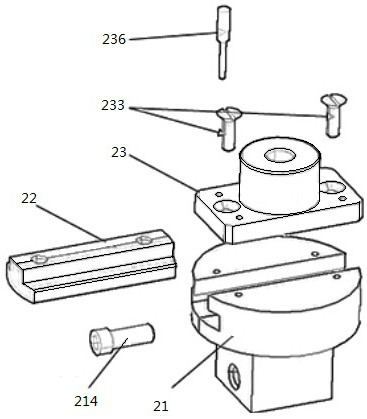

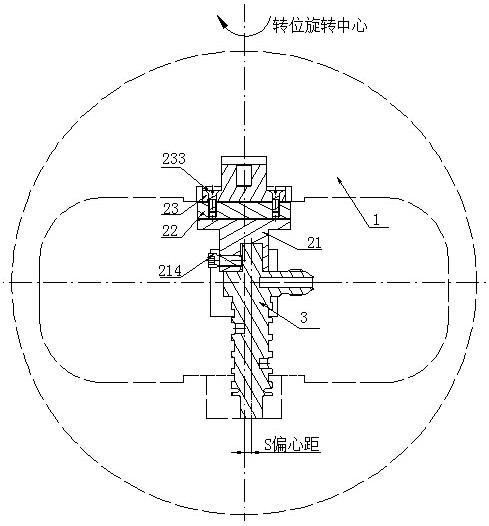

[0023] In order to solve the above-mentioned problems, the inventor of the present application document has proposed a kind of fixture that can be indexed and the eccentric distance can be adjusted on the indexing chuck 1, refer to Figure 1~3 , installed on the index chuck 1 during use, including an adjustment base 23, a slider 22, and a base 21, the adjustment base 23 is connected to the index chuck 1; the slider 22 is connected to the adjustment bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com