Self-clamping mirror shell structure

A self-clamping and mirror housing technology, applied in optical observation devices, transportation and packaging, vehicle parts, etc., can solve the problems of reduced installation efficiency, easy damage to the mirror housing or mirror rod pressure plate, low assembly yield, etc., to reduce Quantity and cost, reducing the risk of jitter, and reducing the effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

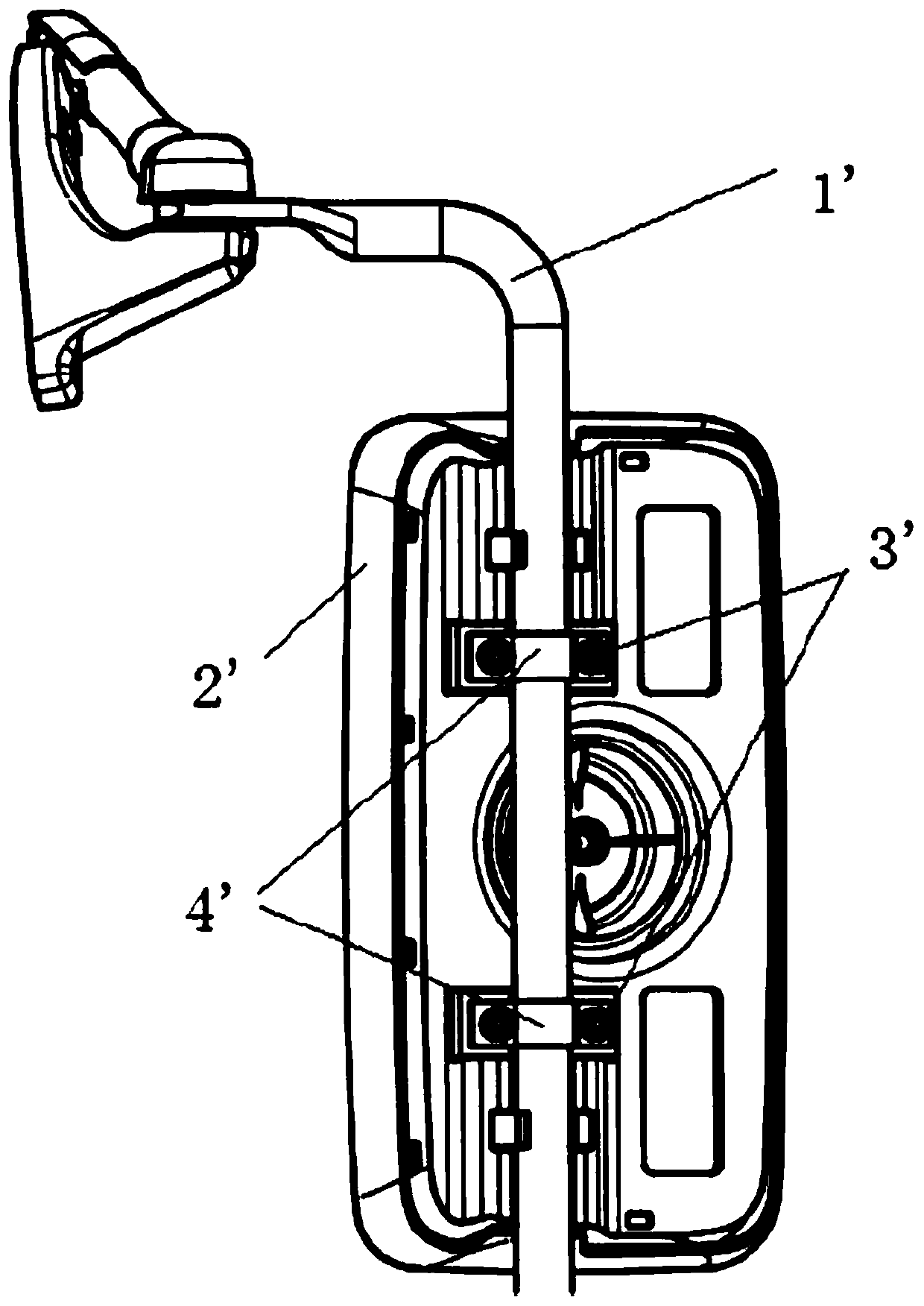

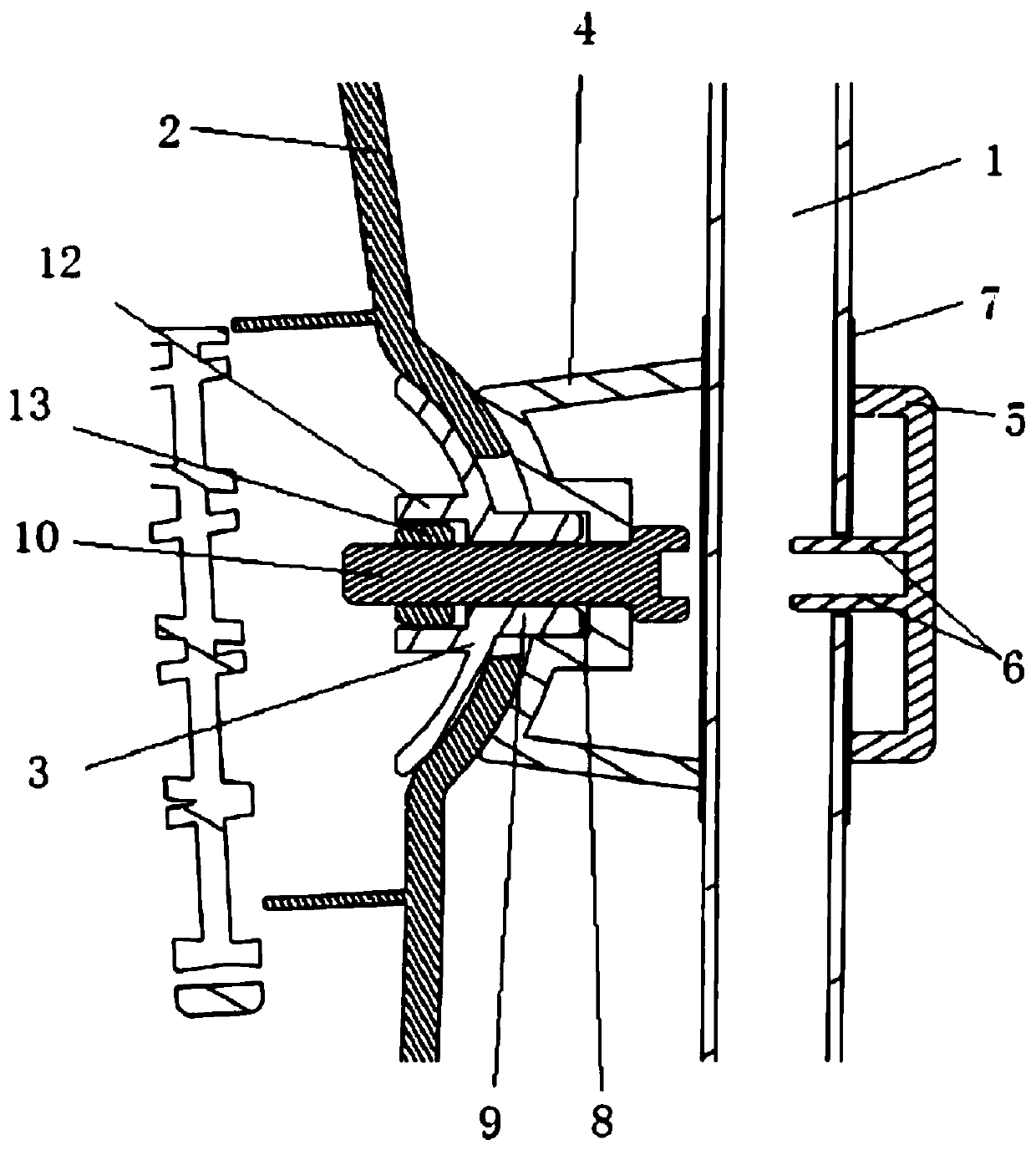

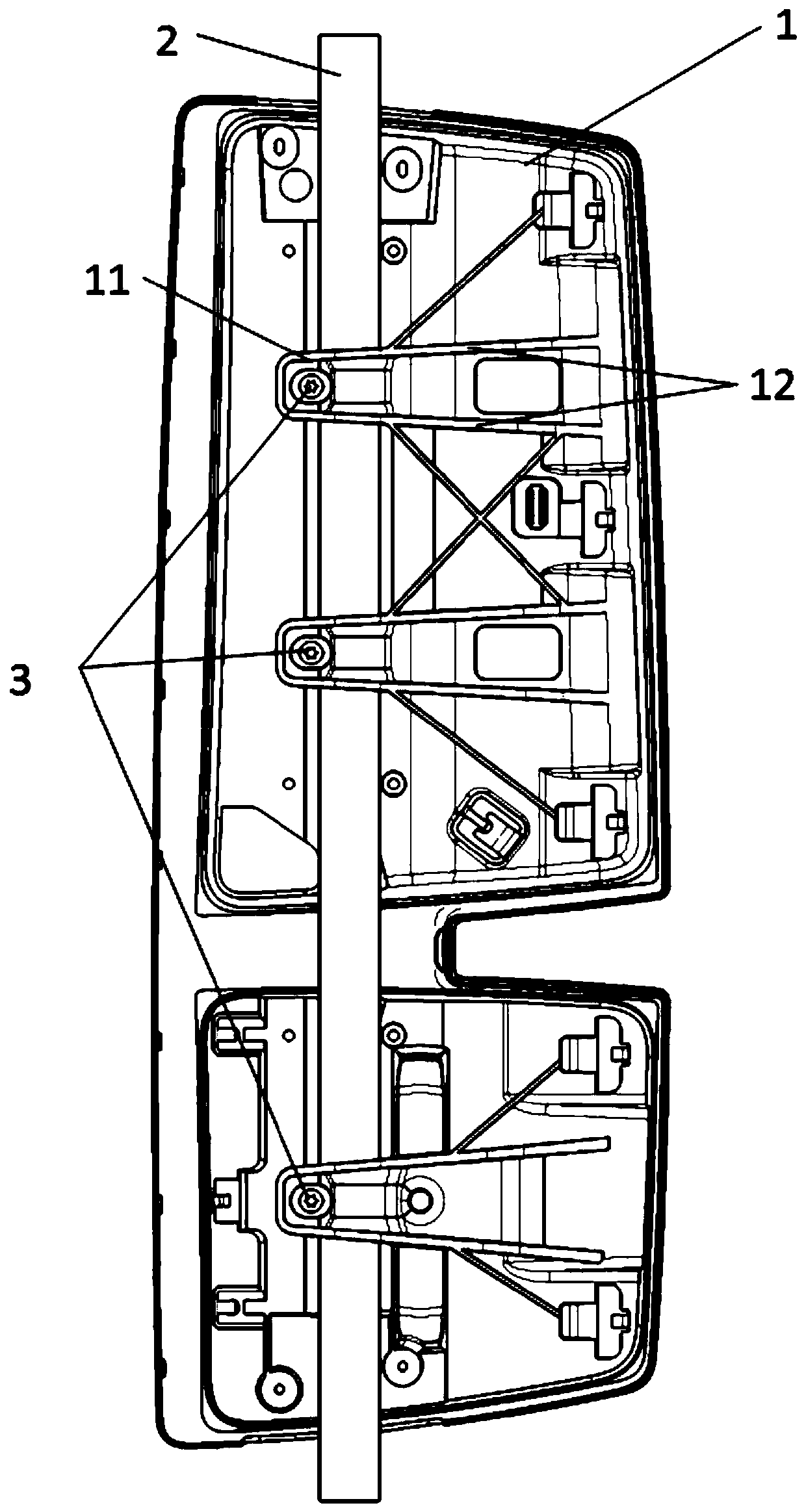

[0025] like Figure 3 to Figure 6 As shown, the present invention provides a self-clamping mirror case structure, which includes a mirror case 1 ; a mirror case clamping piece 11 is integrally formed on the mirror case 1 . There are several mirror housing clamping pieces 11.

[0026] The back side of the mirror case 1 and the mirror case clamping piece 11 form a C-shaped groove for clamping the mirror rod 2 .

[0027] The clamping piece 11 of the mirror case provides the first clamping force for clamping the mirror rod 2; the opening side of the C-shaped groove is provided with a clamping screw 3; the clamping screw 3 provides the second clamping force for clamping the mirror rod 2.

[0028] Under the action of double clamping force, the mirror housing structure of the present invention significantly reduces the risk of shaking of the mirror housing and improves the stability of the rearview mirror in use.

[0029] In particular, a number of mirror housing force transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com