A center of gravity lifting crane anti-sway device

An anti-sway device and lifting technology, which is applied to cranes, trolley cranes, transportation and packaging, etc., can solve problems such as heavy objects are easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

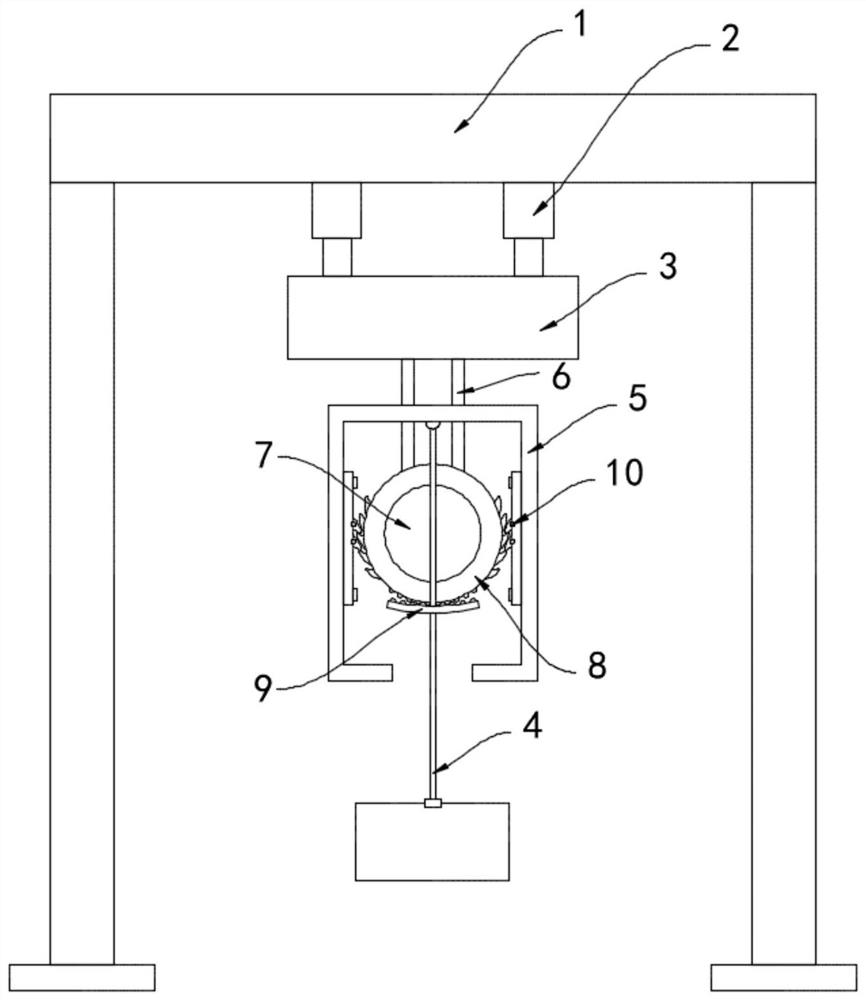

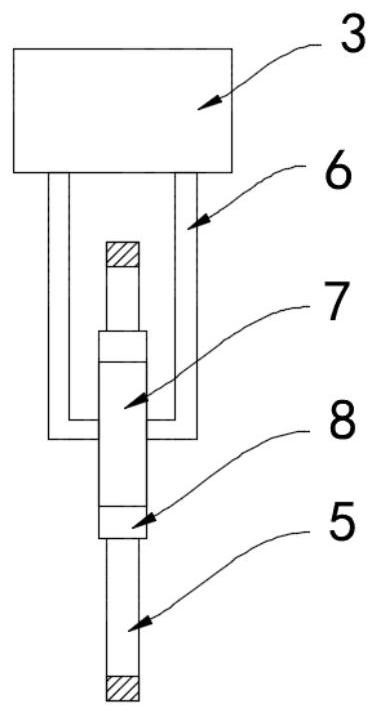

[0019] Such as Figure 1-2 As shown, a center of gravity lifting type crane anti-sway device includes a support frame 1, a lifting mechanism 2, a running trolley 3 and a sling 4, an anti-sway frame 5 is provided under the running trolley 3, and the upper end of the sling 4 is connected to the anti-sway The inner top surface of the rocking frame body 5 is fixedly connected, and the lower end of the running trolley 3 is fixedly connected with two L-shaped connecting rods 6, and a fixed wheel 7 is fixedly installed between the two L-shaped connecting rods 6, and the fixed wheel 7 is located at the In the rocking frame body 5 and parallel to the anti-rolling frame body 5, a rotating ring 8 is connected to the outer ring side wall of the fixed wheel disc 7, and balls are arranged between the fixed wheel disc 7 and the rotating ring 8, so that the sliding friction becomes Rolling friction reduces friction consumption and prolongs its service life. The lower end of the rotating ring ...

Embodiment 2

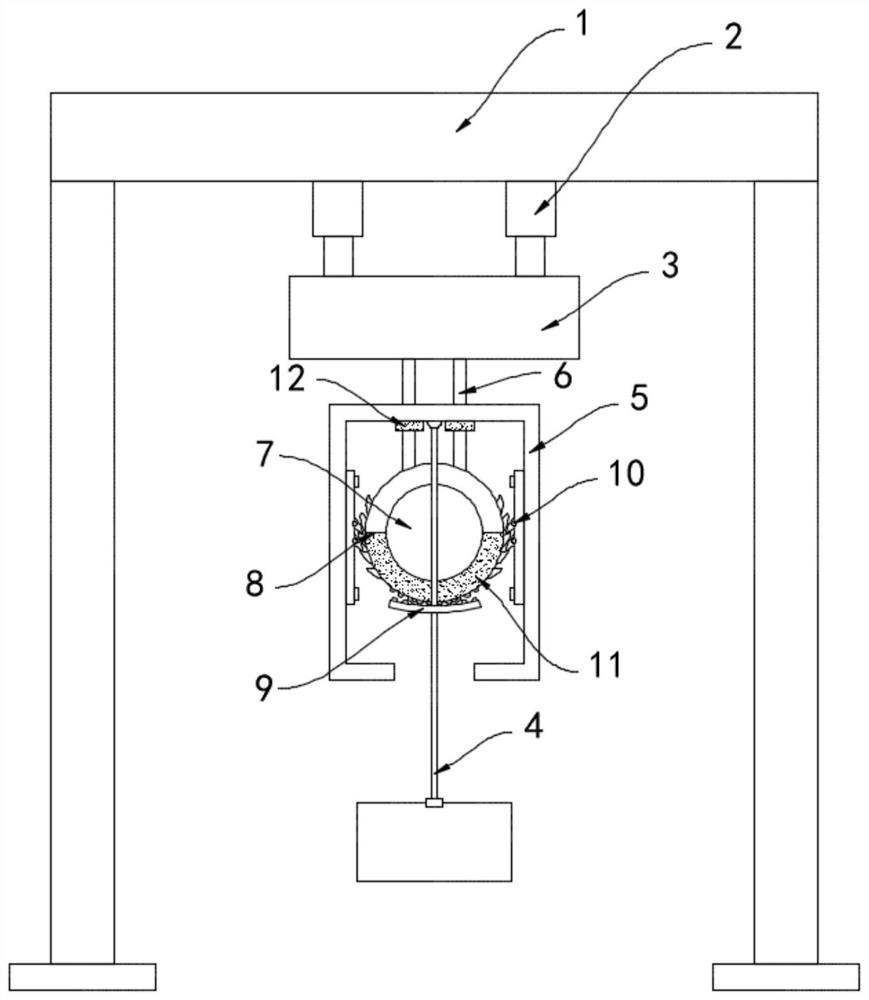

[0023] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the rotating ring 8 is composed of two semi-circular rings 11, the semi-circular ring 11 located below is made of magnetic material, and the inner top surface of the anti-rolling frame 5 A permanent magnet block 12 is fixedly installed, and the same polarity repels each other between the permanent magnet block 12 and the semi-circular ring 11 .

[0024] In this embodiment, when the sling 4 and the heavy object are not swinging, the permanent magnet block 12 is far away from the magnetic semi-circular ring 11, and when the heavy object drives the sling 4 to swing, it drives the rotating ring 8 to rotate, The magnetic semi-circular ring 11 located at the bottom rotates to a higher position and approaches the direction of the permanent magnet block 12, that is, when the sling 4 swings, it needs to overcome the repulsive force between the permanent magnetic block 12 and the semi-circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com