On-line detection method for low cycle fatigue cracks of turbine disk based on Nyquist diagram

A low-cycle fatigue, detection method technology, applied in gas turbine engine testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of long test cycle, increased test cost, and impact on aero-engine development cycle, etc. To achieve the effect of fast and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

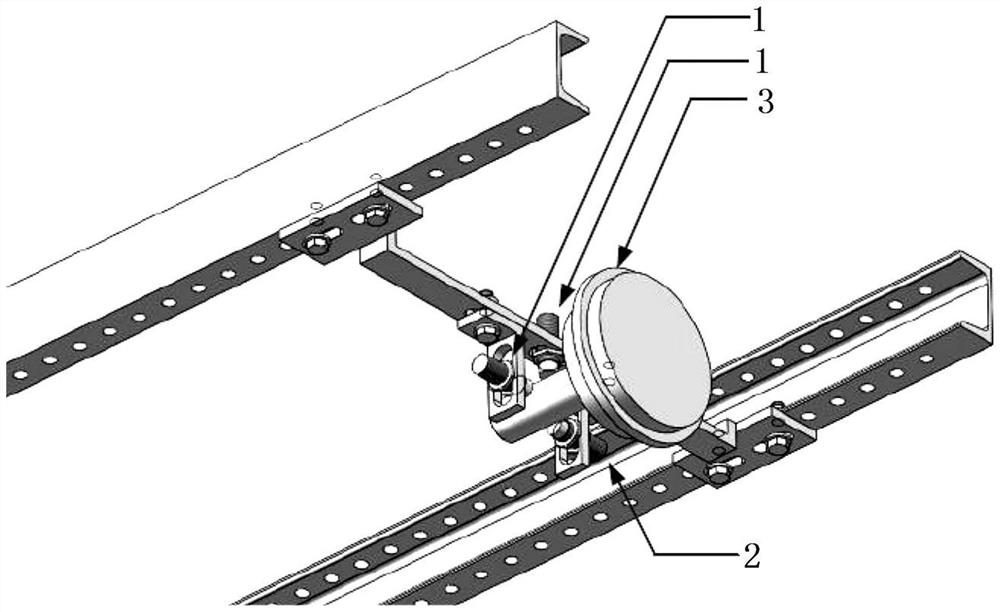

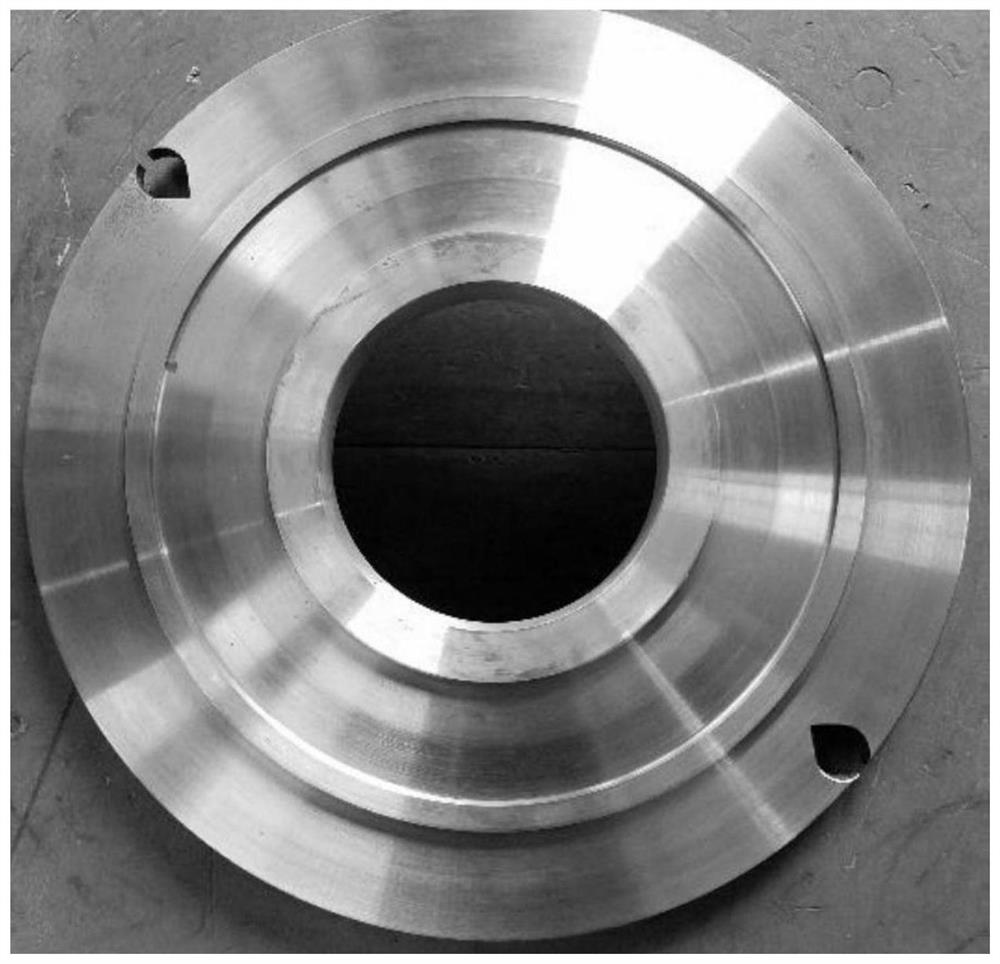

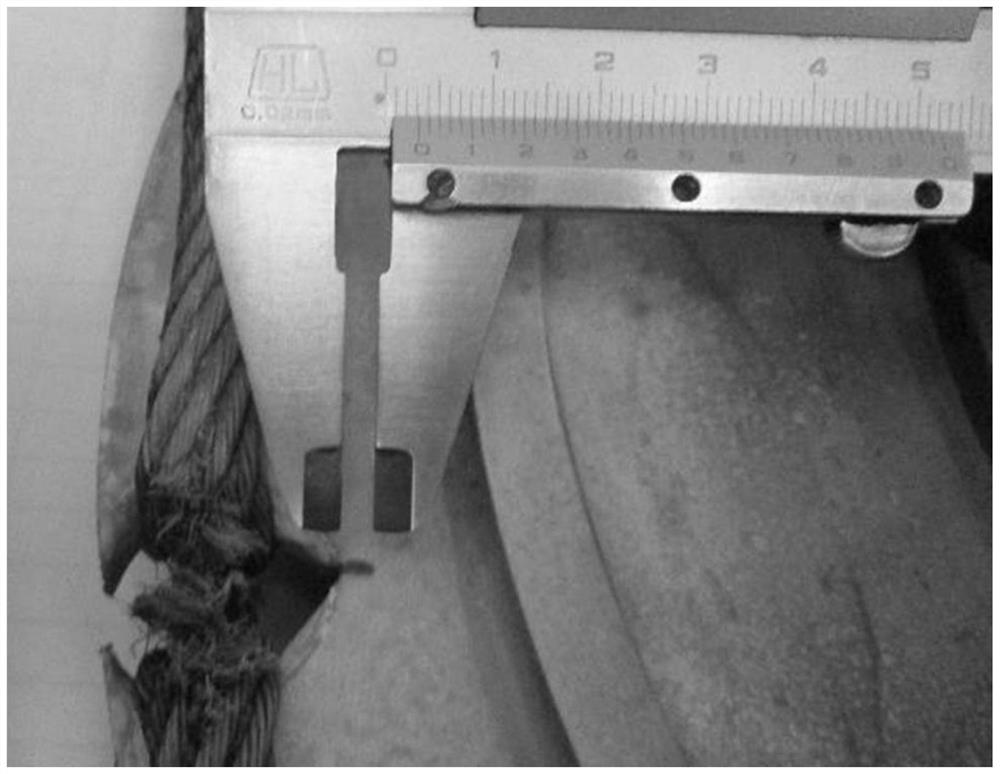

[0049] The invention provides an on-line detection method for low-cycle fatigue cracks of a turbine disk based on a Nyquist diagram. In a low-cycle fatigue test of a turbine disk, the radial displacement vibration signal of the wheel disk shaft and the key phase pulse signal are obtained online; Synchronous averaging is used to preprocess the vibration signal of the radial displacement of the wheel shaft to remove the white noise contained in the signal; the real part and imaginary part of the crack index at different speeds are extracted from the denoised signal by using the full-period discrete Fourier transform , use the real part and imaginary part of the crack indicator in the loading process and unloading process to draw the crack indication Nyquist diagram; then judge whether there is a crack in the turbine disk by whether the loading curve and the unloading curve cross in the crack indication Nyquist diagram. The invention can realize the on-line detection of disc crack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com