Subgrade structure, subgrade system and design method of anti-bulge and wide subgrade adjacent to ballastless railway

A design method and system design technology, applied in design optimization/simulation, roads, buildings, etc., can solve problems such as increasing the amount of land used, and achieve the effect of saving construction land, bearing the overall load of the structure, and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

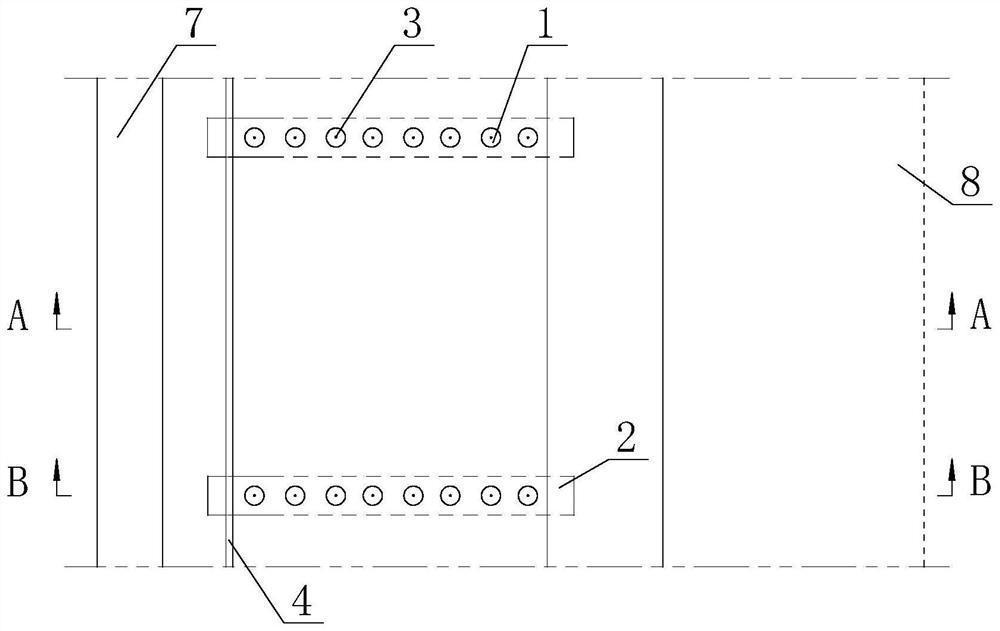

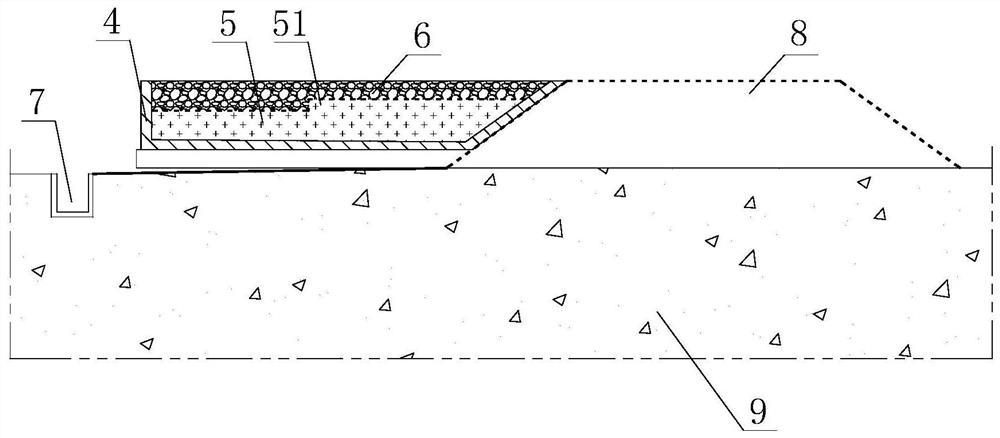

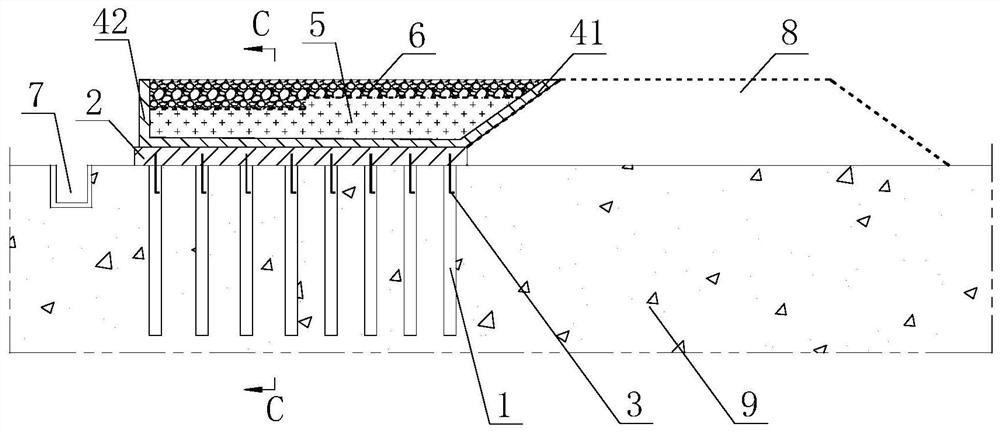

[0073] like Figure 1-4 As shown, a kind of anti-bulge and wide roadbed structure adjacent to the ballastless railway described in this embodiment includes:

[0074] The reinforcement piles 11 are arranged in a row along the line direction adjacent to the existing ballastless track subgrade 8; the support beams 2 are arranged on the top of the reinforcement piles 11;

[0075] Connecting steel bar 3, one end is anchored into the pile body, and one end is fixedly connected with the support beam 2;

[0076] The hopper 4 is arranged on the top of the support beam 2 in sections along the longitudinal direction of the line;

[0077] The light soil layer 5 and the soil filler layer 6 are filled in the storage tank 4 in sequence from bottom to top;

[0078] The drainage ditch 7 is arranged on the side of the hopper 4 away from the existing ballastless track roadbed 8 .

[0079] In the above scenario:

[0080] The length of the reinforcement piles 11 is not less than 1.2 times the ...

Embodiment 2

[0088] like Figure 1-4 As shown in the figure, a subgrade system using the anti-uplift and wide subgrade structure adjacent to the ballastless railway in this embodiment includes a foundation 9, the reinforcing piles 11 are arranged in the foundation 9, and the support beam 2 Set on the foundation 9, there is a gap between the hopper 4 between the adjacent support beams 2 and the foundation 9, and the inclined cantilever 41 is in contact with the slope of the existing ballastless track roadbed 8 combine.

[0089] In the subgrade system of the present invention, which adopts the anti-uplift subgrade structure close to the ballastless railway, the inclined cantilever 41 is fitted with the side slope of the existing ballastless track subgrade 8 to ensure the subgrade structure of the ballastless railway. To meet the basic use requirements, the support beam 2 is arranged on the foundation 9, that is, it can be used to transfer the load of the hopper 4 to the foundation 9 and the...

Embodiment 3

[0094] like Figure 1-5 As shown, a design method for the subgrade system, comprising the following steps:

[0095] ① Determine the structural weight W of the support beam 2 by the following formula z :

[0096] W z =BLHγ c

[0097] where W z is the structural weight of the supporting beam 2, unit kN; B is the width of the supporting beam 2, the unit is m; L is the length of the supporting beam 2, the unit is m; H is the height of the supporting beam 2, the unit is m; γ c is the weight of reinforced concrete, in kN / m 3 ;

[0098] ② Determine the structural weight W of the hopper 4 by the following formula u :

[0099]

[0100] where W u is the structural weight of the holding tank 4, in kN; b is the width of the holding tank 4, in m; h 1 is the thickness of the bottom plate of the holding tank 4, the unit is m; h is the height of the holding tank 4, the unit is m; h 2 is the cantilever thickness of the hopper 4, in m; m is the slope rate of the existing ballastl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com