Vehicle front end structure and manufacturing method thereof

A manufacturing method and automobile technology, applied in the field of automobile parts, can solve the problems of complex forming process of parts, low production efficiency of final assembly, low integration of parts, etc., so as to improve the side impact resistance performance, improve the production efficiency of final assembly, and reduce the difficulty of assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0038] The invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete. In the drawings, the size and relative sizes of structures and regions may be exaggerated for clarity.

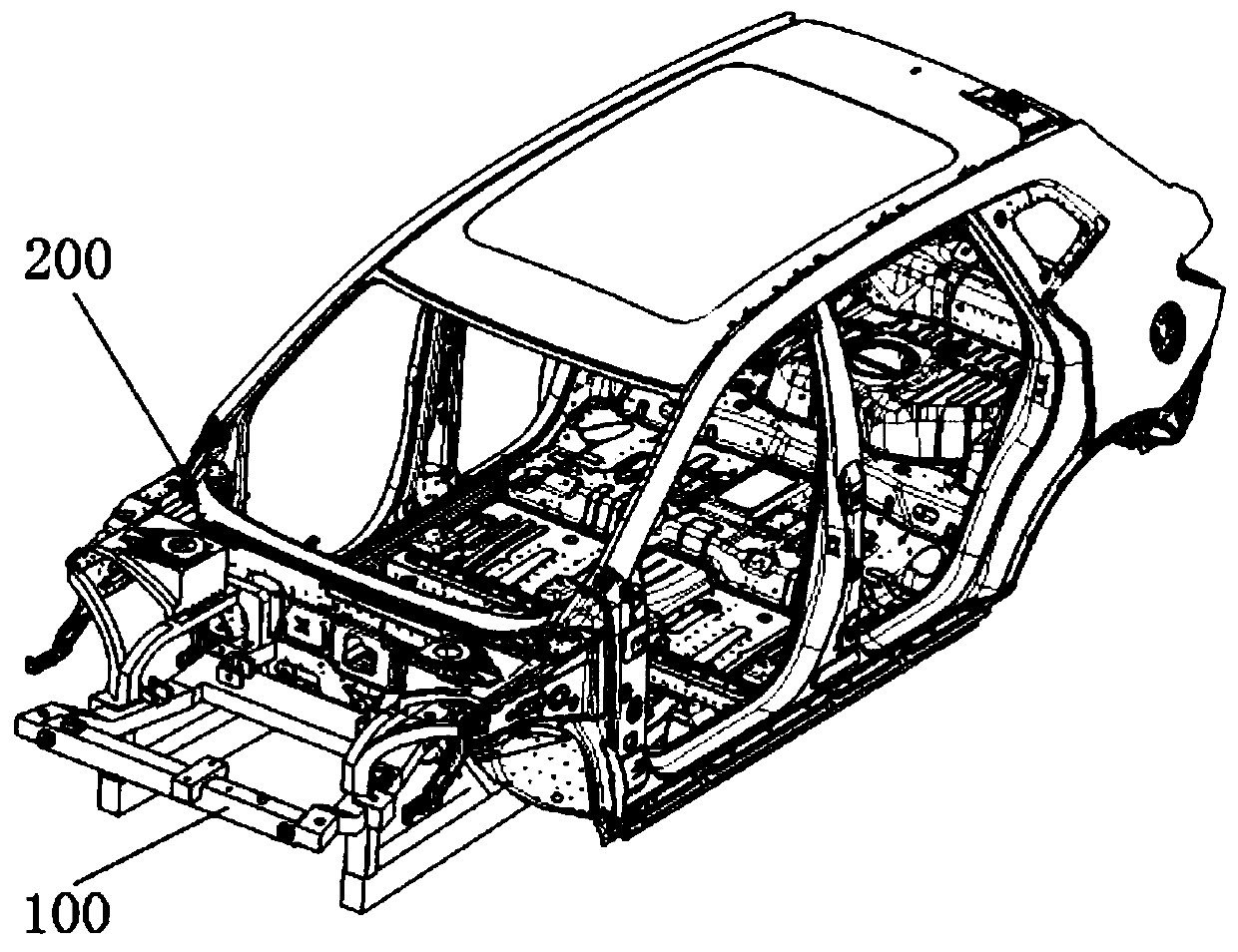

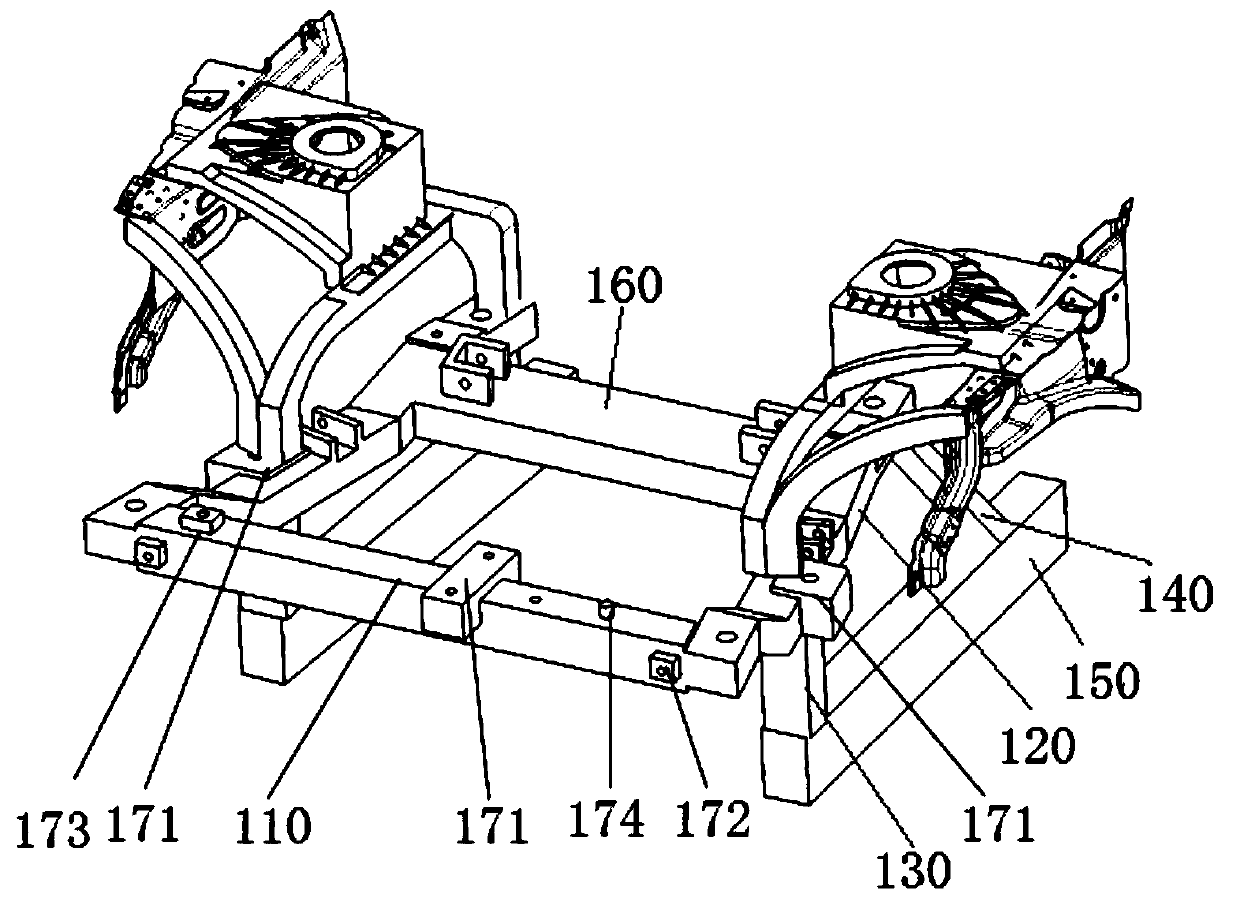

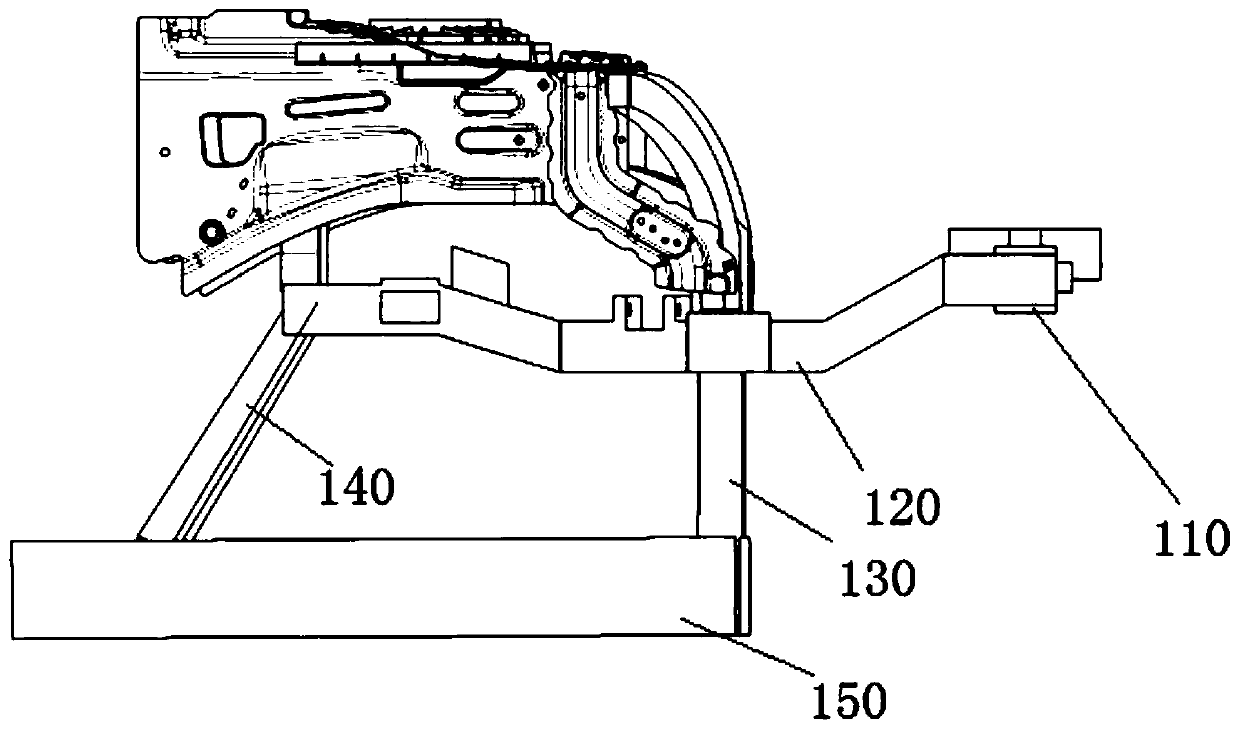

[0039] like Figure 1-3 As shown, the present invention provides a vehicle front end structure 100, comprising: a front cross member 110, which is a straight structure; Straight structure, the rear end is bent upward; the first support beam 130 is vertically connected with the upward bending part of the front end of the first front longitudinal beam 120; the second support beam 140 is connected with the first front longitudinal beam 140 120, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com