A method for measuring the surface profile of a linear white light

A technology of surface profile and measurement method, applied in the field of new line white light surface profile measurement, which can solve the problems of large volume, splicing error affecting measurement accuracy, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below with reference to the accompanying drawings and examples.

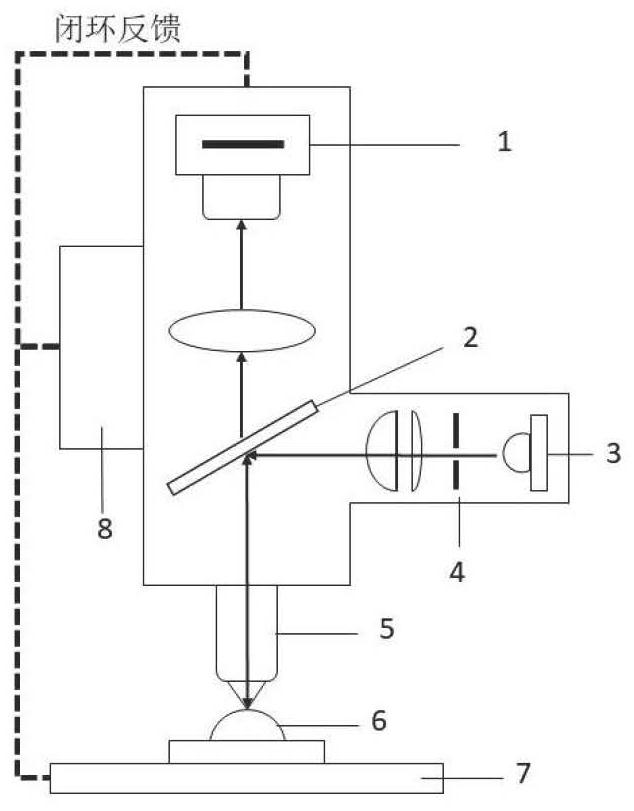

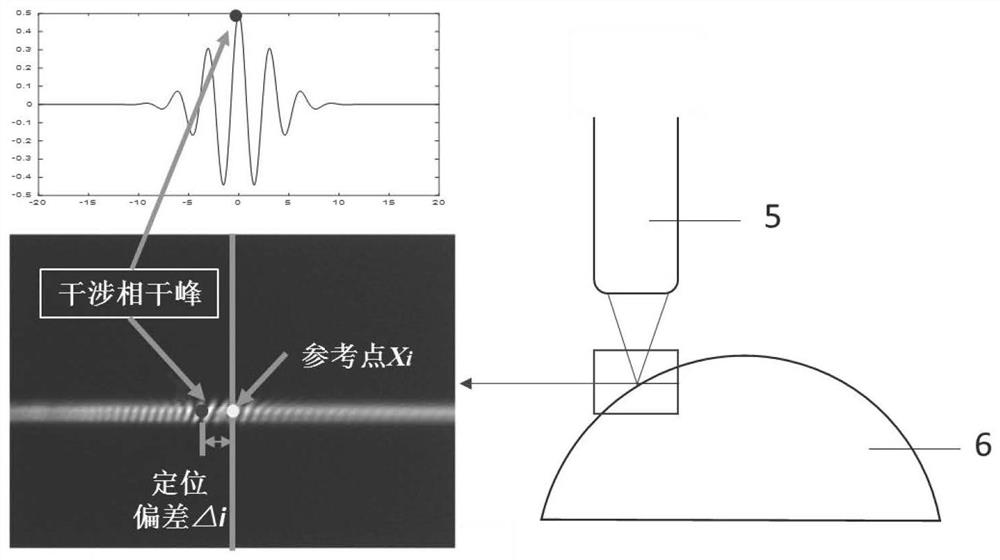

[0018] The present invention proposes a new type of white surface profile scan measurement, using white light interference nano measurement accuracy characteristics, expanding white light interference measurement capability, and realizes the measurement of low frequency surface profile. The CCD camera of the measuring system is integrated into a high-precision axial shift platform, and the axial displacement platform controls the CCD camera to scan movement over the height direction of the measured sample in its measuring range, and drive the sampled edge of the X-axis. The scanning direction is moved at a constant speed, and the CCD camera is automatically focused after each measurement point. Planning grid type scanning path measurement is measured on this surface to realize full-size information measurement characterization. In this method, the CCD camera is responsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com