Artificial board surface defect detection method

A defect detection and wood-based panel technology, applied in the directions of optical testing flaws/defects, measuring devices, material analysis by optical means, etc., can solve the problems of poor detection effect, low detection efficiency, high labor intensity, etc., and achieve high accuracy , the effect of high integrity and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 , figure 2 Shown, a kind of wood-based panel surface defect detection method of the present invention comprises the following steps:

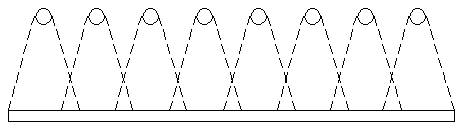

[0017] 1) Use multiple high-definition scanners erected above and below the wood-based panel conveyor to continuously scan the surface of the wood-based panel, and store the scanned images on a computer connected to the high-definition scanner. The width direction of the wood-based panels is arranged in sequence, and the scanning area of the high-definition scanner is set as a square area of fixed size. After all the square areas are superimposed, they cover the width area of the wood-based panel in the scanning area, and the adjacent square areas partially overlap;

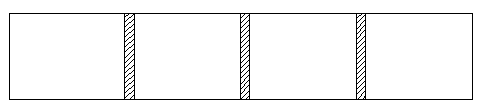

[0018] 2) Define the positional relationship of multiple scanned images obtained by setting the coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com