Automatic composite material laying execution device

An automatic layer laying and execution device technology, applied in lamination, layered products, lamination auxiliary operations, etc., can solve the problems of low efficiency of manual layer laying, achieve efficient transfer and laying, avoid loss, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

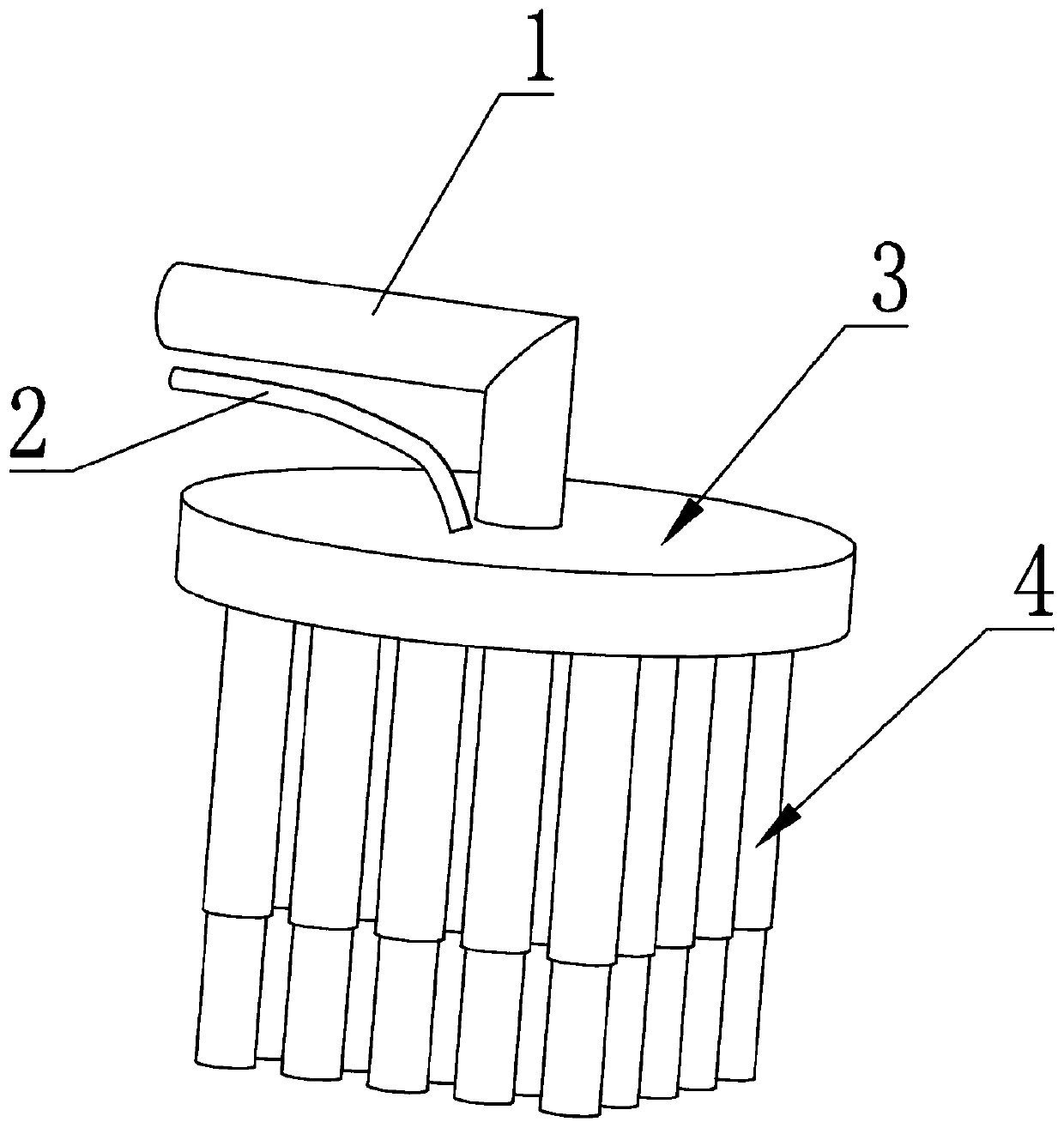

[0029] see figure 1 As shown, the composite material automatic lay-up execution device provided by the embodiment of the present invention is generally used in cooperation with the mechanical arm 1 or similar structures to realize the positional movement of the composite material automatic lay-up execution device.

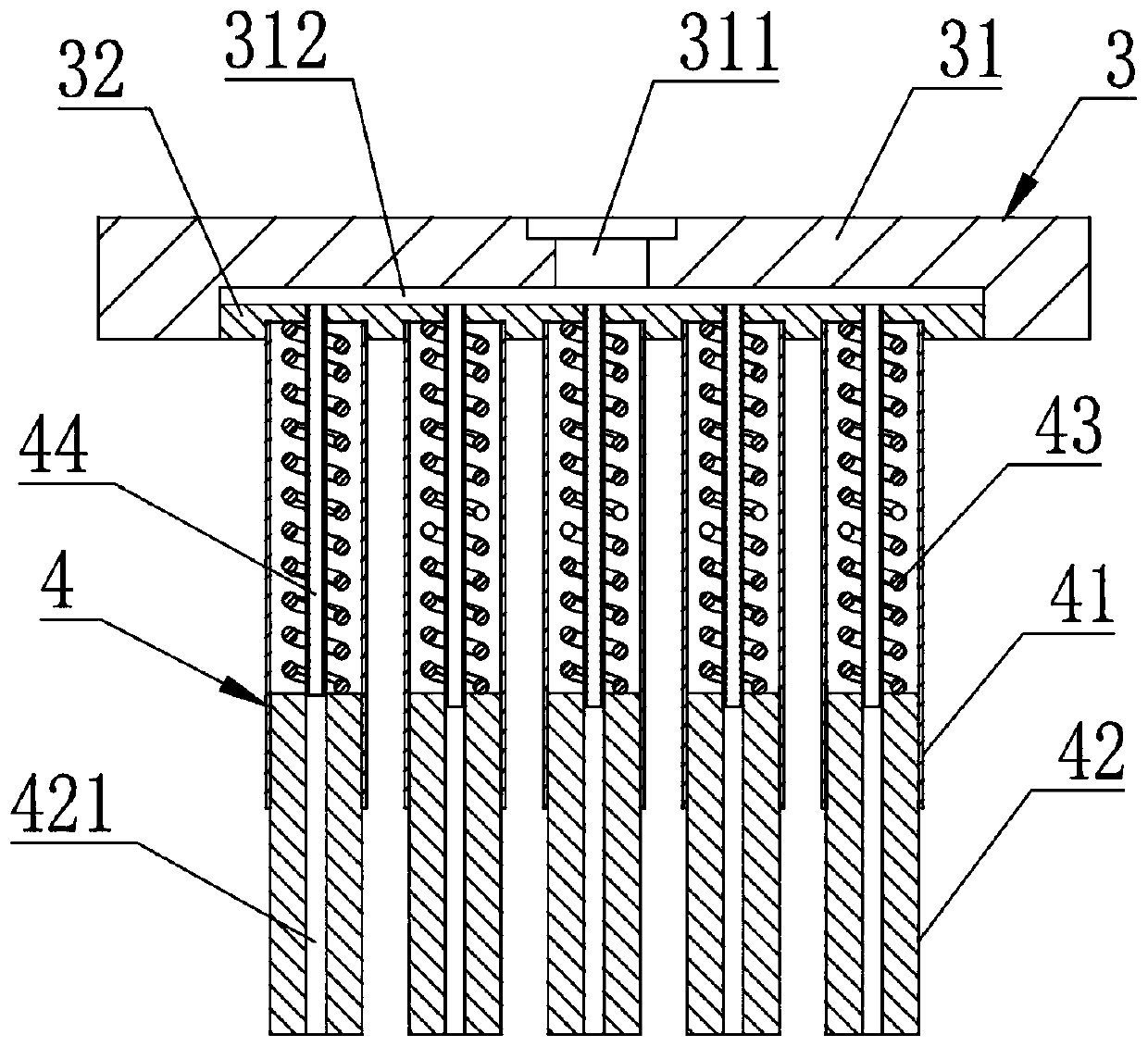

[0030] see figure 1 and figure 2 As shown, the composite material automatic lay-up execution device includes an adsorption plate 3 and a plurality of adsorption units 4, and the plurality of adsorption units 4 are arranged in parallel and distributed on the lower side of the adsorption plate 3. The size of the adsorption plate 3 and the adsorption unit 4 The quantity is positively related to the size or quality of the prepreg to be laid. If the size or quality of the prepreg to be laid is large, more or smaller adsorption units 4 need to be installed. If the adsorption units 4 If the quantity is large, a larger size adsorption plate 3 is required. The plurality ...

Embodiment 2

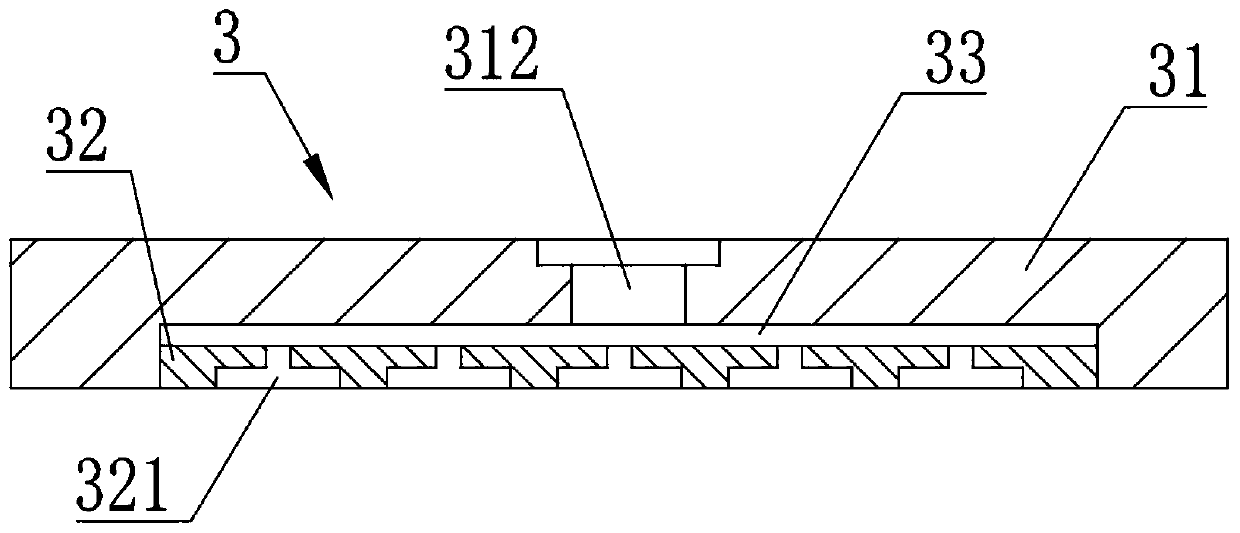

[0041] see Figure 6 As shown, the second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that the adsorption disc 3 has an integrated structure, and the adsorption disc 3 is provided with multiple holes penetrating the adsorption disc 3 in the axial direction. A gas distribution channel 33, and the upper port of each gas distribution channel 33 is communicated with a negative pressure pipe 2 (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com