Method for forming weak protective layer above mine roadway

A protective layer and roadway technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve the problems of poor environmental protection and high risk of weak protective layers, and achieve the goal of improving efficiency, environmental protection and safety, and improving effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

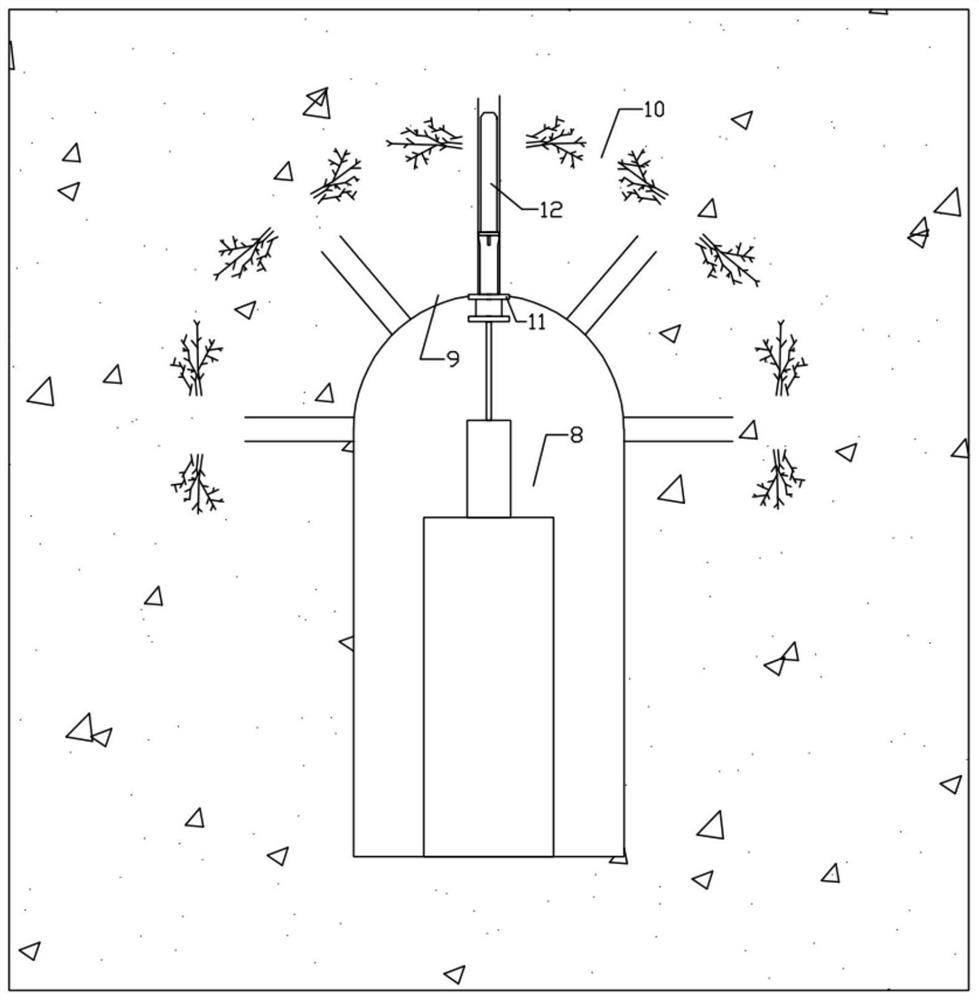

[0033] A method for forming a weak protective layer above a mine roadway, comprising an energy converter 12 and an orifice device 11 .

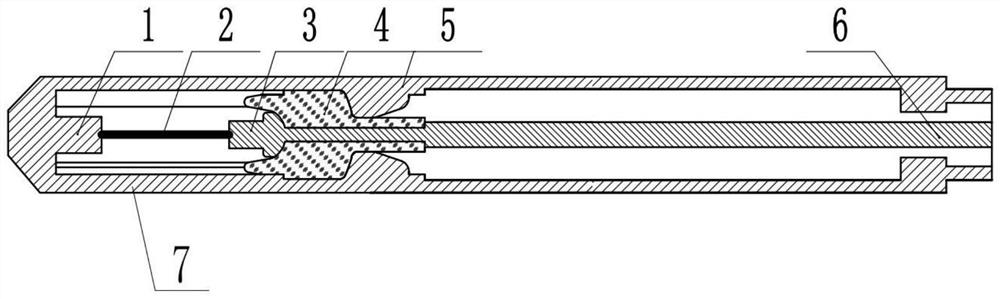

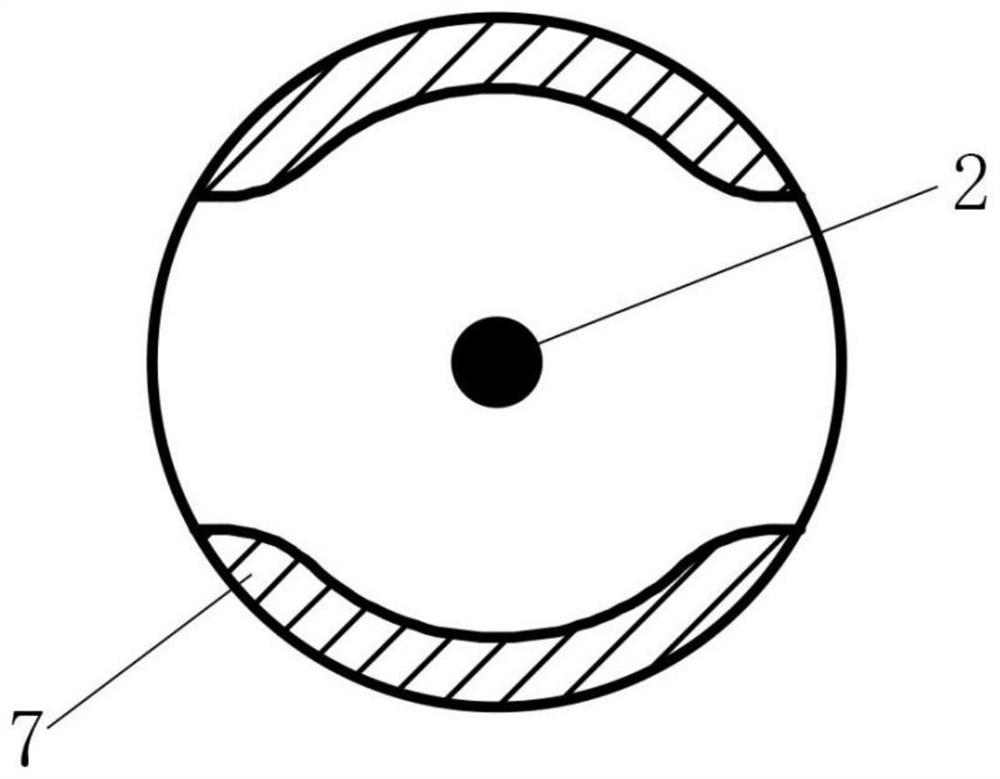

[0034] like figure 2 , image 3 As shown, the energy converter 12 includes a ground electrode 1 , a metal wire 2 , a high voltage electrode 3 , an insulating support 4 , a casing 5 , a cable interface 6 and a shock wave directional reflective arc plate 7 .

[0035] The shell 5 is a cylindrical structure, and its interior is hollow. The high-voltage electrode 3 is fixed on the end of the shell 5 through the insulating support 4. The cable at the end of the cable interface 6 passes through the body of the shell 5, the insulating support 4 and the rear end of the high-voltage electrode 3. connection, the ground electrode 1 is connected to the front end of the housing 5 through two shoc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap