Split wheel-mounted brake discs for rail vehicles

A rail vehicle, split technology, applied in the direction of brake disc, brake type, brake components, etc., to achieve the effect of improving the pass rate, reducing the risk of defects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

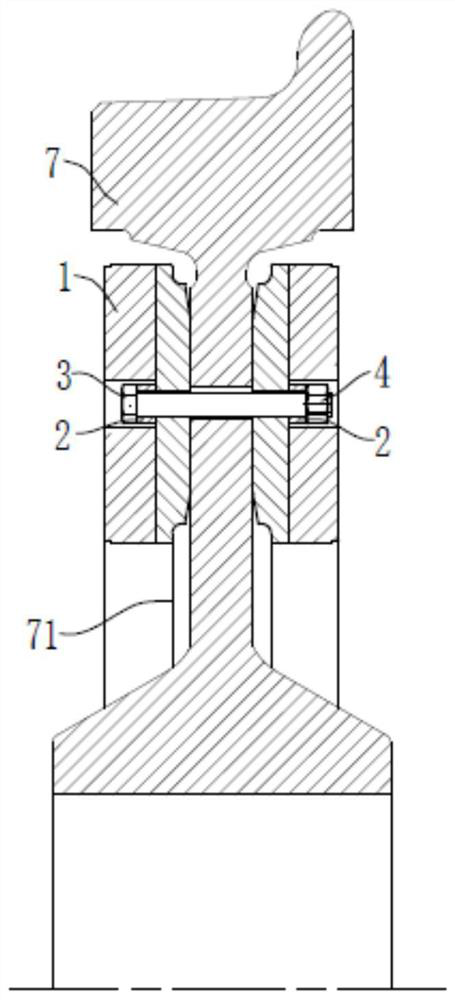

[0043] refer to figure 1 and Figure 14 , The split-type wheel-mounted brake disc for rail vehicles includes a split-type disc body 1, a spacer 2, bolts 3, nuts 4, positioning pins 5, O-rings 6 and wheels 7. The split disc body composition 1 is located on both sides of the wheel web 71 .

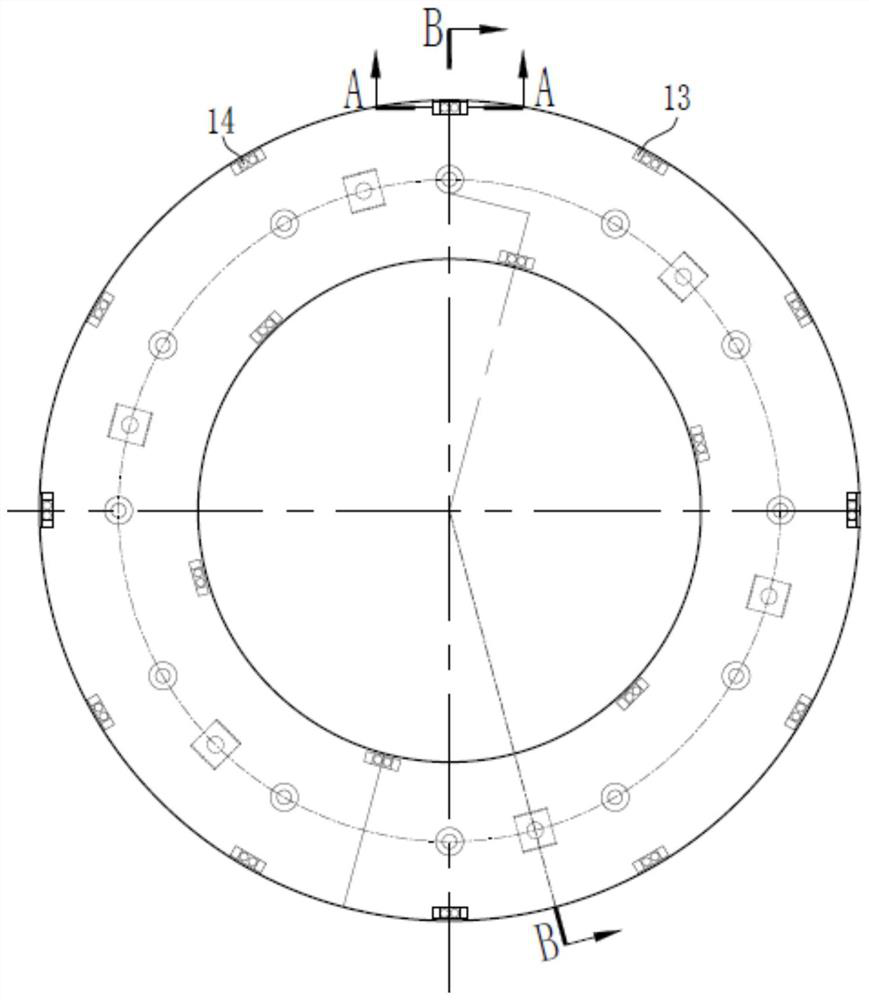

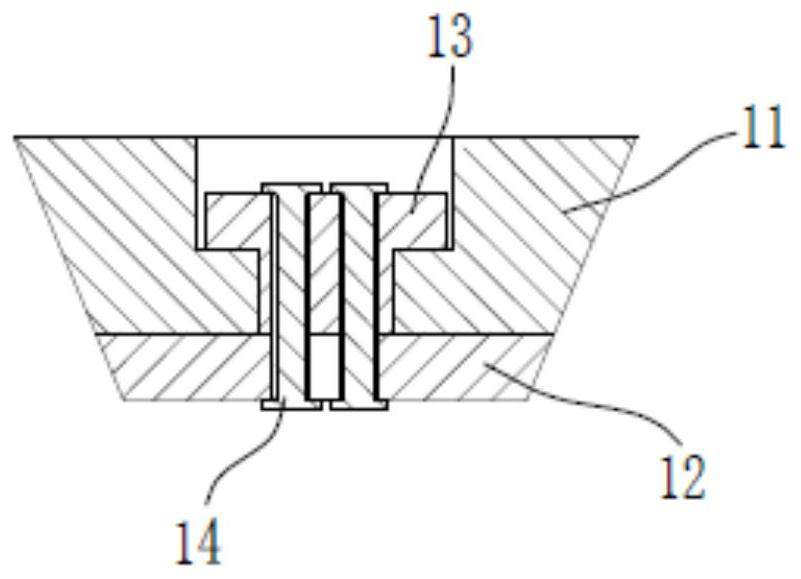

[0044] refer to Figure 2 to Figure 4, The single-piece split disc body composition 1 includes two split friction rings 11 , an integral steel frame 12 , a pressure block 13 , a rivet 14 and a slider 15 .

[0045] refer to Figure 5 to Figure 7 , the planes on both sides of the split friction ring 11 are the friction surface 111 and the chute surface 112 respectively, 6 friction ring through holes 114 are evenly distributed on the middle circle 113 of the friction ring, and 6 outer pressure blocks are evenly distributed on the friction surface 111 Slot 115 and four inner briquetting grooves 116; the outer briquetting groove 115 and the inner briquetting groove 116 are identical in struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com