A method and special equipment and filter bag for making the bottom of a dust filter bag

A filter bag and bag bottom technology, which is applied in the field of environmental protection and dust removal, can solve the problems of complex structure, difficult operation, and high cost of the bag bottom of the dust filter bag, and achieve the effect of eliminating the problem of dust discharge channels, eliminating cloth seams, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

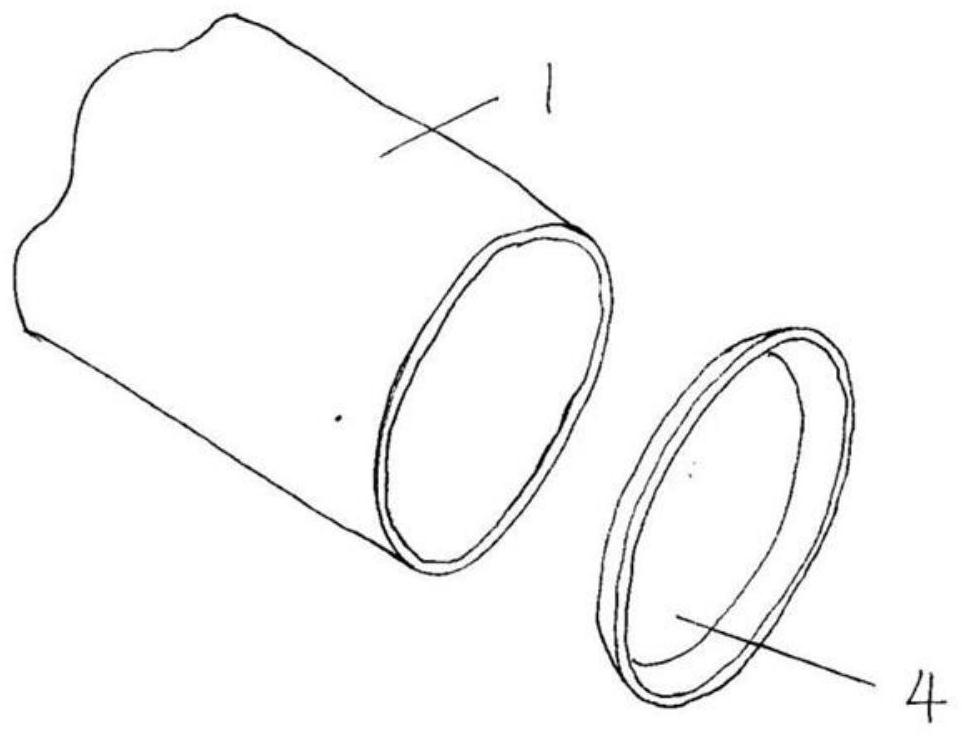

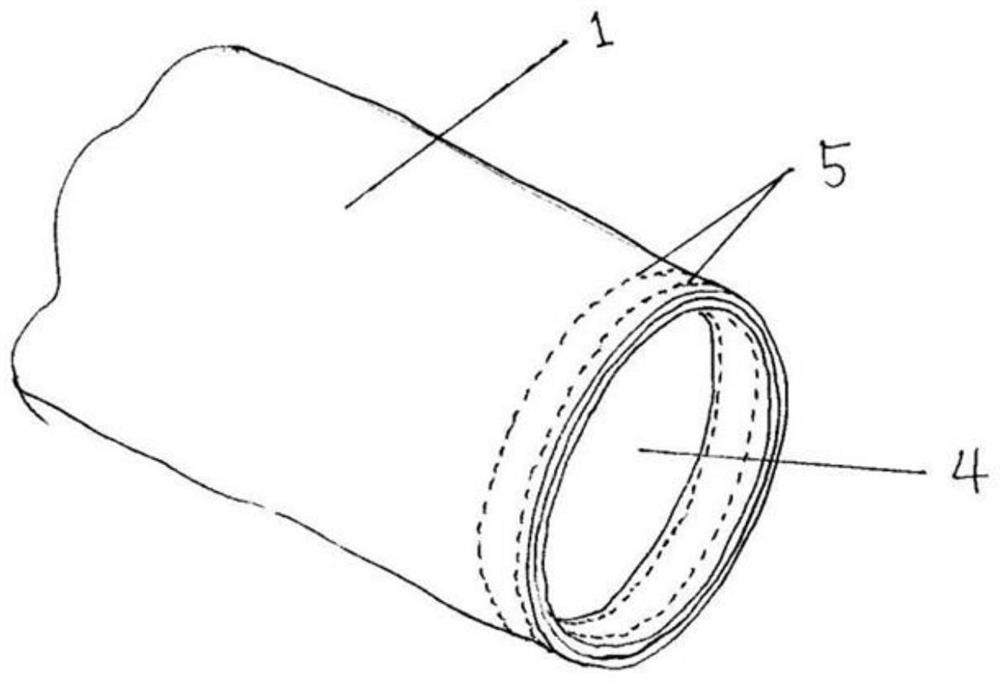

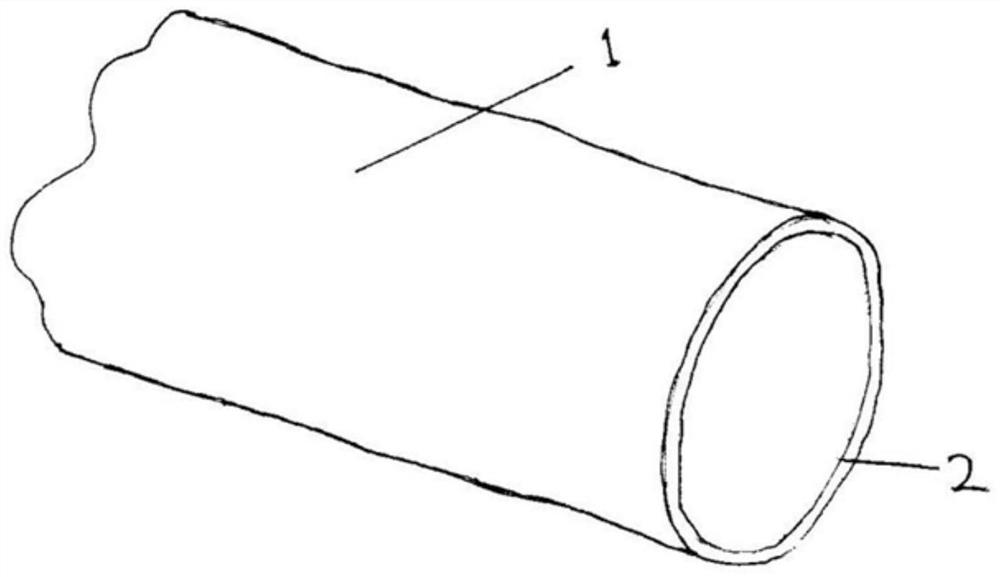

[0074] Such as image 3 , 4 As shown, the port 2 at the bottom end of the cylindrical bag body 1 is tightly gathered into a pinch 2' in the middle by external force, and then a C-shaped buckle 8 made of metal is used to cover the gathered filter material. The C-shaped buckle 8 used in this embodiment is spiral-shaped when viewed from the side. Then use a strong external force to make the inner diameter of the C-shaped buckle 8 shrink inwardly to produce larger plastic deformation, and its two ends are staggered and overlapped, and the bottom port 2' of the bag body after being gathered into a pinch is tightly locked. After the buckle 3 after plastic deformation loses the external force and recovers part of the deformation, it forms a stable shape that can resist a certain external force, and can still maintain the state of tightly squeezing the gathered filter materials together to ensure that the dust does not pass through channel. In addition, the tightness should also e...

Embodiment 2

[0076] Such as Figure 10 As shown, when the cutting edge 22 of the shearing device cuts out the port of the bag body that is used as the bottom of the bag, the walking mechanism (also called a trolley) of the equipment described in this patent moves synchronously in the forward direction according to the moving speed of the filter material of the production line, and the right poly Pinching template 23 and left gather pinching template 24 at distance bag body port 2-5cm place, relative movement advances to the middle part, until tubular bag body filter material is tightly squeezed into a pinch. The degree of tightness is based on the impermeability of dust and the fact that the filter bag will not fall off under working conditions. It can be realized by presetting the maximum propulsion force of the transmission mechanism. The transmission mechanism can be various transmission forms such as air cylinders, hydraulic cylinders, and electric motors.

[0077] The spring 9 in th...

Embodiment 3

[0079] Such as Figure 9 As shown, different from Embodiment 2, there is no upper press-lock push head 13 in this embodiment, and the left and right press-lock push heads are composed of two sets of press-lock action cylinders 11 and a press-lock roller 12 respectively. Each set of press-lock action cylinders can realize all-round continuous extrusion of the buckle 8 through the hinge connection and movement of the push rod, and finally complete the locking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com