A soil filling bucket used in construction engineering

A construction engineering, sliding sleeve technology, applied in the application, planting method, excavation/covering trenches and other directions, can solve the problems of increased energy consumption, frequent excavator movement, low efficiency, etc., to achieve low production cost, simple structure, The effect of improving soil backfilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

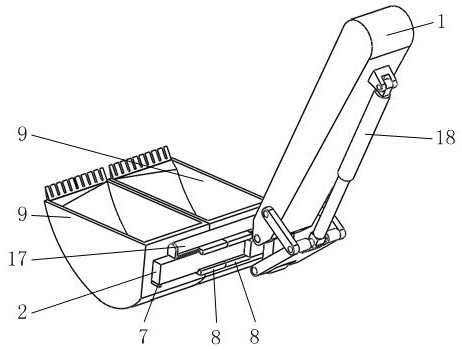

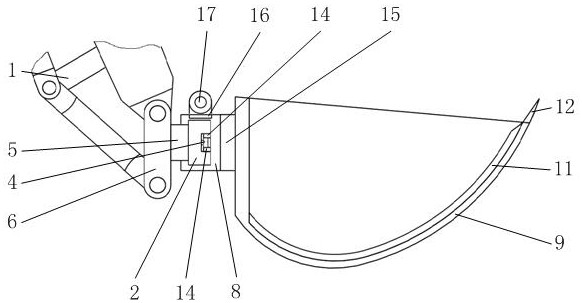

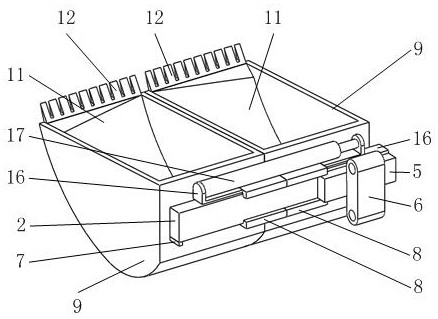

[0026] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0027] Such as figure 1 , 3 As shown, it includes a guide rail 2, a gear 4, a connecting block 5, a connecting plate 6, a sliding sleeve 8, a bucket 9, a rotating shaft 10, a rack 14, and a hydraulic column 17, among which figure 1 , 2 , 10, the connecting plate 6 is hinged to the end of the excavator boom 1 to form a four-link swing mechanism driven by the hydraulic device 18; as figure 2 , 3 As shown in , 6, the connecting plate 6 is equipped with a horizontally arranged guide rail 2 through the connecting block 5, and there are two sliding sleeves 8 synchronously sliding opposite or opposite to each other on the guide rail 2; as figure 1 , 3 , 5, the two L plates 16 symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com