A clamping device for a lint filter, a lint filter, and a washing machine

A technology of lint filter and connecting parts, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problem that the lint filter is easy to fall off, and achieve the effect of preventing falling off and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

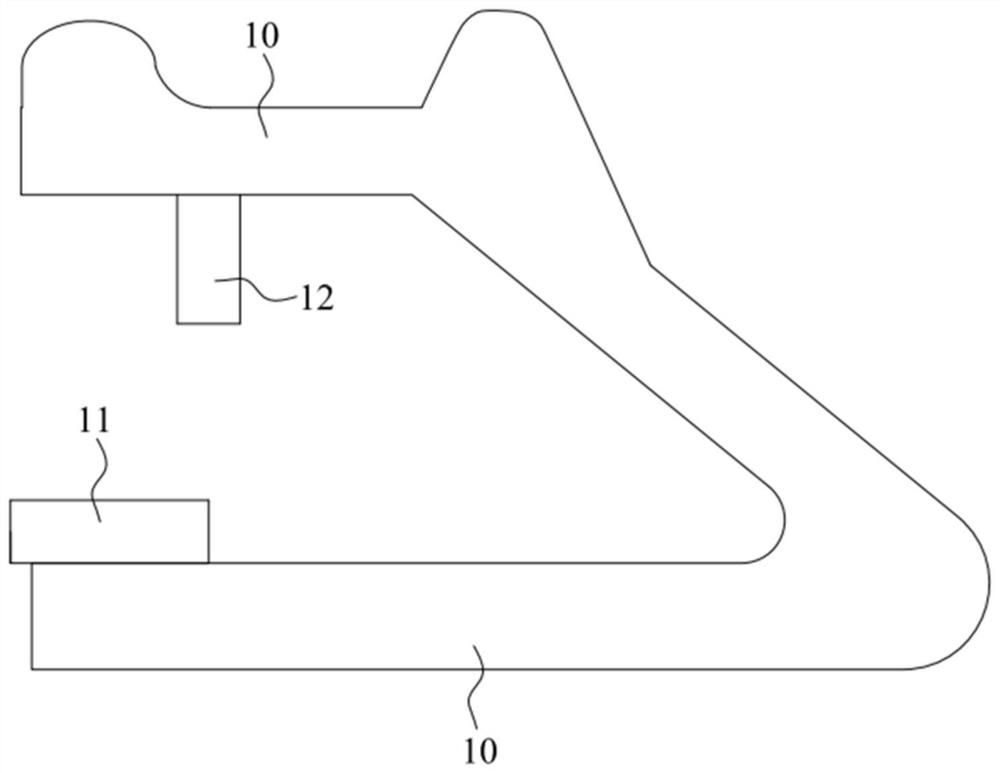

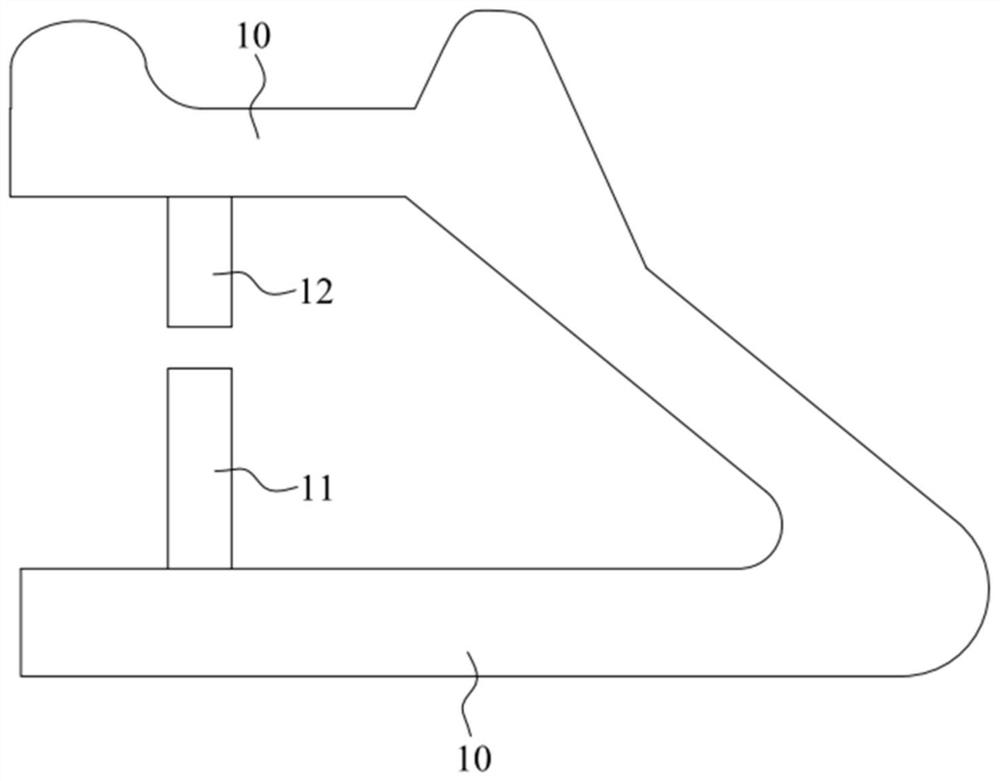

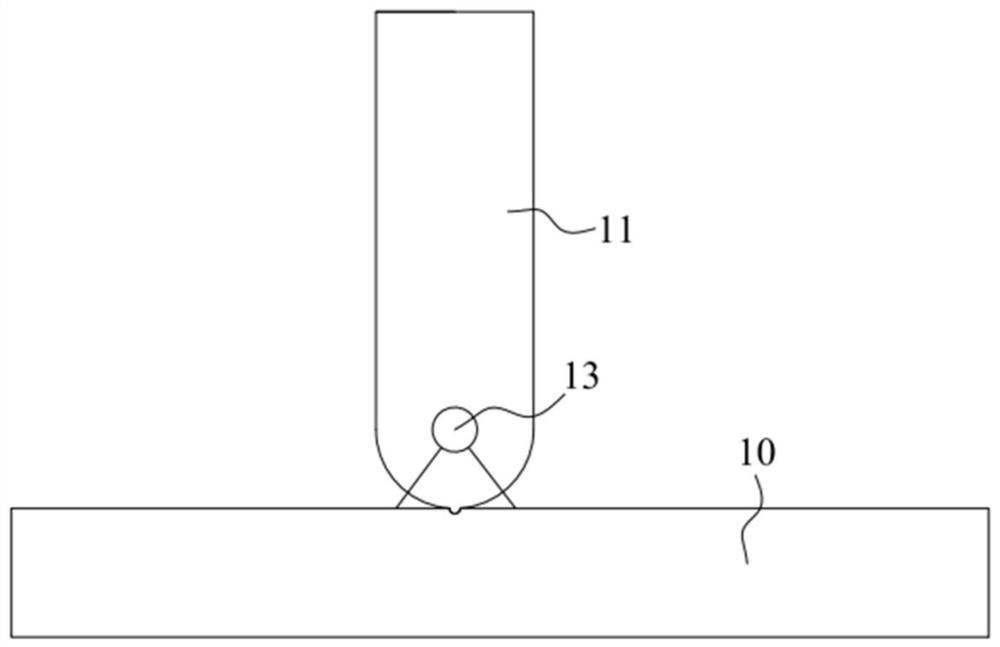

[0033] see Figure 1 to Figure 3 , the embodiment of the present invention provides a clamping device for a lint filter, which is used to install the lint filter on a washing machine.

[0034] The clamping device includes two elastic arms 10 , one end of the two elastic arms 10 is connected, and the other end is spaced apart, thereby forming a clamping opening between the two elastic arms 10 . By pressing one elastic arm 10 , the two elastic arms 10 can be brought close to each other, and the lint filter can be installed and removed.

[0035] The two elastic arms 10 can be arranged in parallel or at an included angle. If the two elastic arms 10 are parallel, one side of the two elastic arms 10 is connected by a connecting piece. The two elastic arms 10 can be integrally formed, that is, formed by bending one elastic plate several times. The shape of the clamping device is not limited here, and may be U-shaped, triangular or trapezoidal as shown in the figure.

[0036] A li...

Embodiment 2

[0044] Figure 4The second embodiment is shown, in which the same or corresponding parts and components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For simplicity, only the differences between the second embodiment and the first embodiment are described. The difference is that one end of the limiting portion is connected with one elastic arm 10 , and the distance between the other end of the limiting portion and the other elastic arm 10 is adjustable.

[0045] The limiting portion includes a moving member 21 , one end of the moving member 21 is threadedly connected with one elastic arm 10 , and the other end of the moving member 21 is selectively abutted with another elastic arm 10 . When the moving member 21 is rotated, the moving member 21 can move linearly along its axis, thereby increasing or reducing the distance between the other end of the moving member 21 and the other elastic arm 10 .

[0046] During in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com