A gas-liquid two-phase flushing nozzle and sanitation vehicle

A sanitation vehicle and gas-liquid technology, applied in cleaning methods, road surface cleaning, construction, etc., can solve problems such as the decline in the cleaning effect, the impact of the volume of the garbage bin, and the residual water on the ground, so as to achieve a complete garbage push effect and ensure the cleaning effect. The effect of sweeping normal operation and reducing the use of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

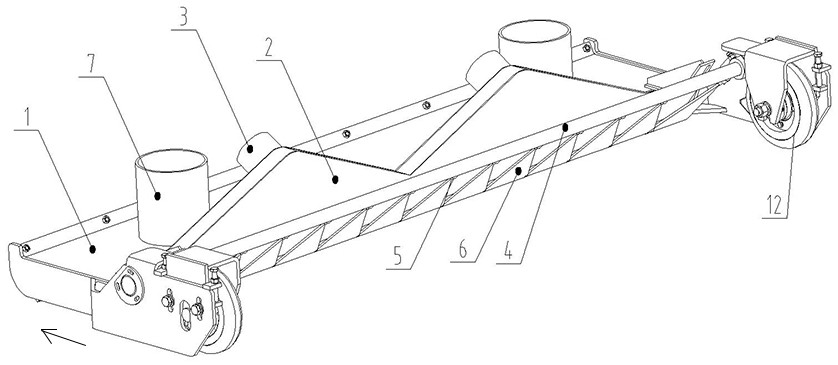

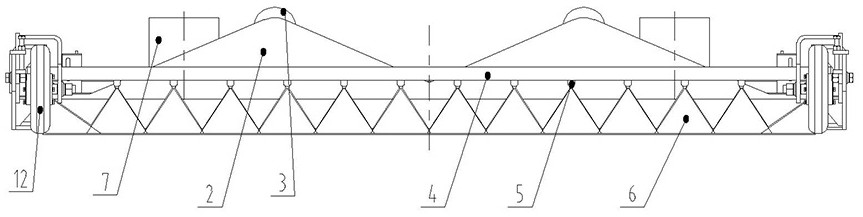

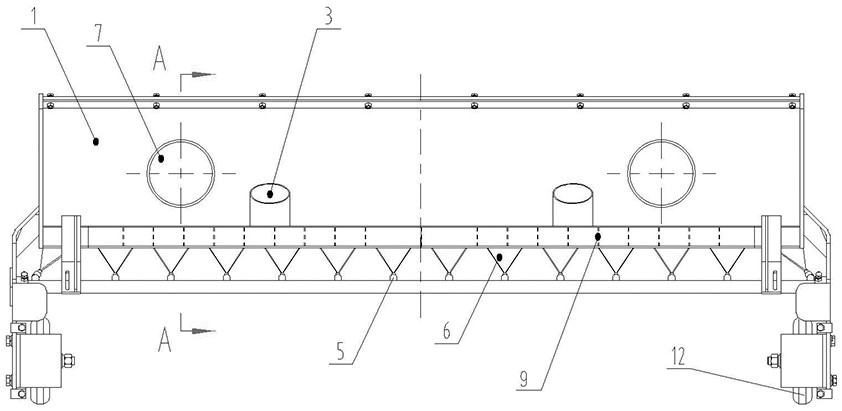

[0028] The present invention takes the running direction of the sanitation vehicle as the front, and vice versa. The running direction of the sanitation vehicle is as follows: figure 1 in the direction of the arrow.

[0029] like Figure 1-5 As shown, a gas-liquid two-phase rinsing suction nozzle includes a suction nozzle body 1, the upper surface of the suction nozzle body 1 is welded with a suction pipe 7 and a high-pressure spray gun 4, and the lower side of the high-pressure spray gun 4 is spaced along its axial direction. The high-pressure nozzle 5 of the front injection, an intake air duct 2 is arranged between the suction pipe 7 and the high-pressure spray gun 4, the upper end of the intake air duct 2 is welded with an air intake pipe 3, and the lower end extends through the nozzle body 1 into Inside the cavity of the nozzle body 1 .

[0030] In order to prevent the bulky garbage from blocking the intake air duct 2 and the high-pressure nozzle 5, and to make the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com