Sprayed concrete and surrounding rock fracture detection device and method

A technology of shotcrete and detection device, which is applied to measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. The damage of shotcrete and surrounding rock cannot be detected, and the whole process evolution of fracture damage cannot be clearly understood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the essence of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

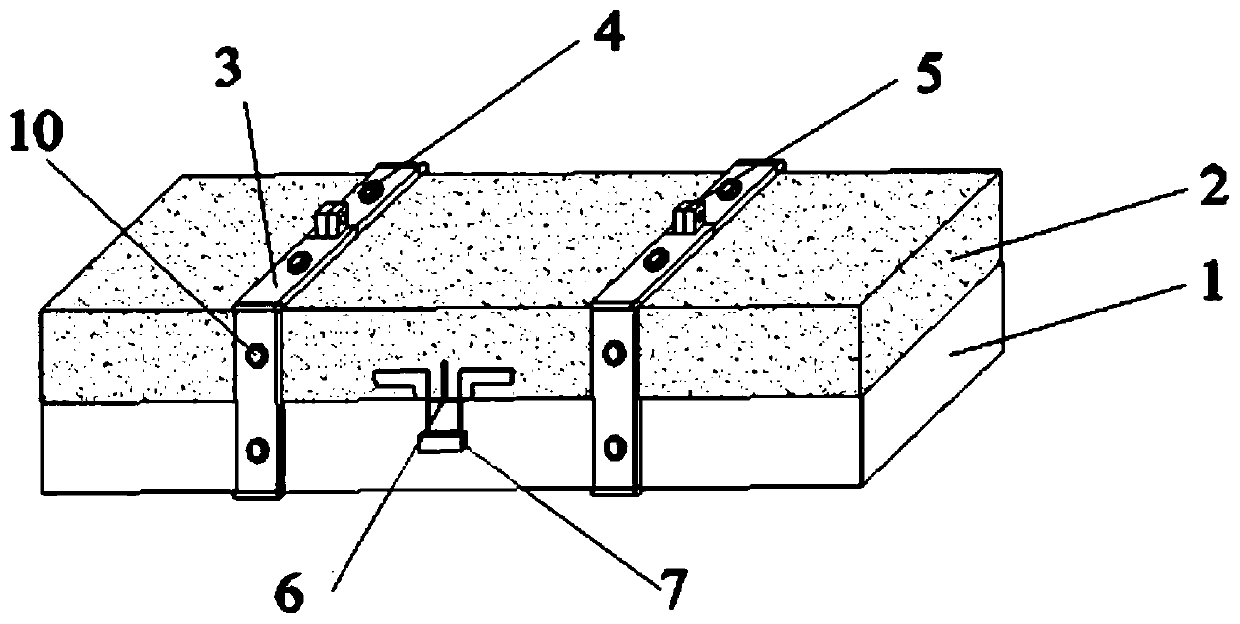

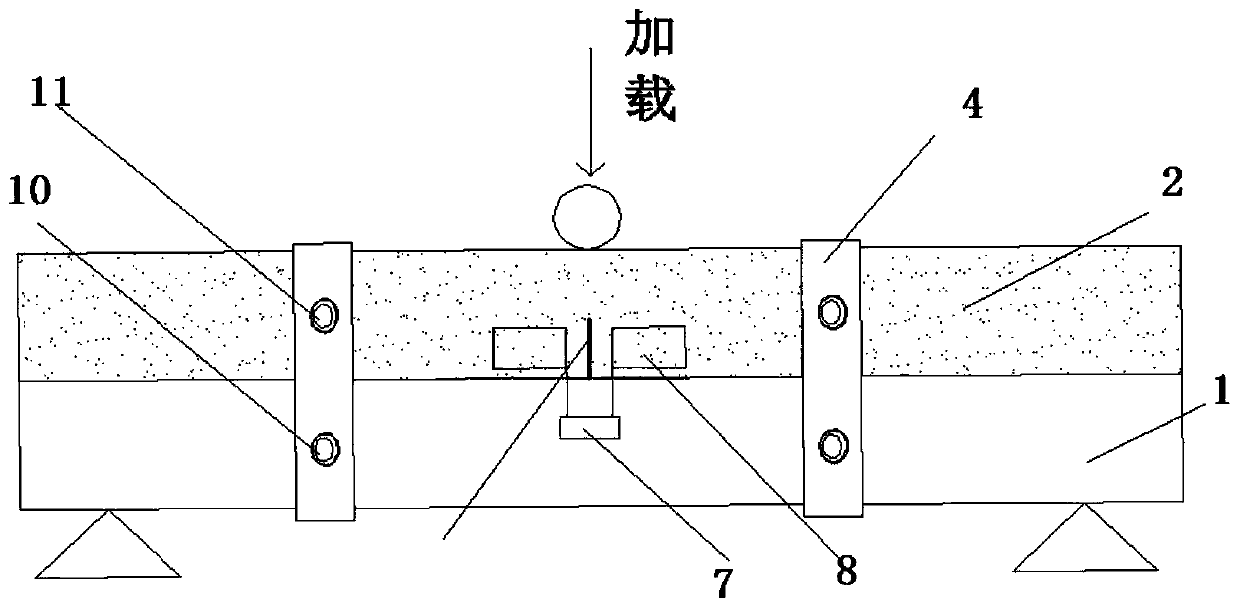

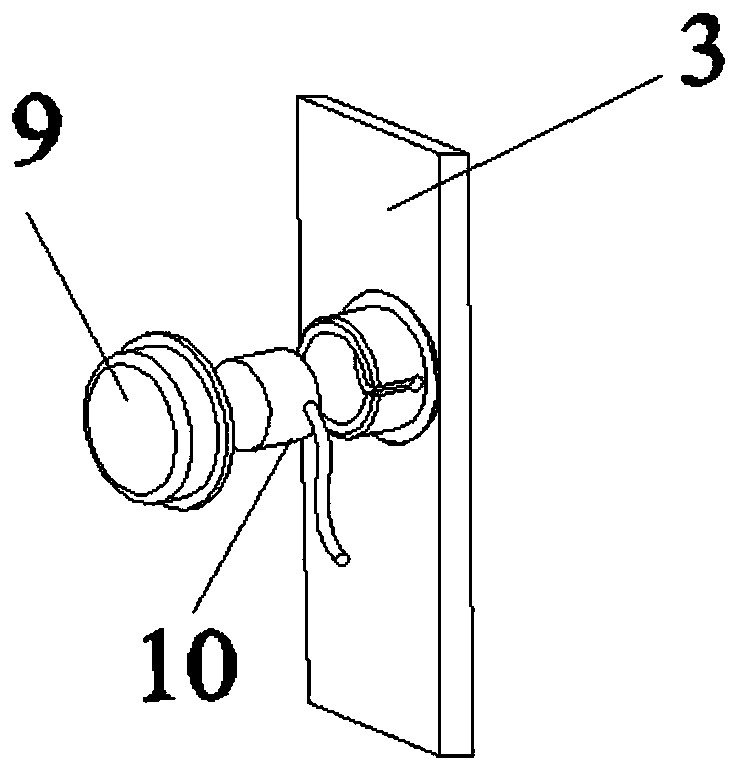

[0033] The invention belongs to the field of concrete structures and materials, and is especially suitable for the detection of shotcrete and surrounding rock fractures. The specific embodiment structure is as follows Figure 1 to Figure 4 As shown, it includes a plurality of detection units, an extensometer 7 and a prefabricated seam 6 . The detection unit is installed on both sides of the prefabricated seam 6, and the extensometer 7 is installed at the prefabricated seam 6. The detection unit includes a bracket, an ultrasonic emitting device 10 and an ultrasonic receiving device 11 . The ultrasonic emitting device 10 and the ultrasonic receiving device 11 are installed on the bracket, and are sealed and fixed by the sensor cap 9 . The bracket includes an iron ferrule and a bayo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com