Two-stage detection method and system for structural corrosion based on rapid vibration test

A technology of vibration testing and detection methods, which is applied in the processing of detection response signals, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to achieve the effects of strong anti-noise ability, less test time, fast positioning and quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

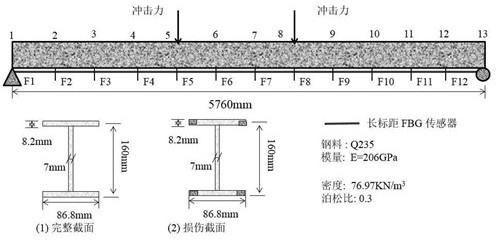

[0062] A two-stage strategy for structural corrosion detection based on rapid vibration, including the following steps:

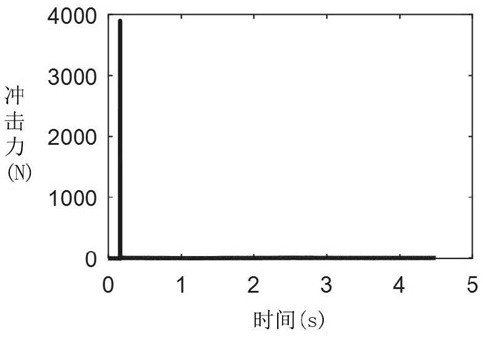

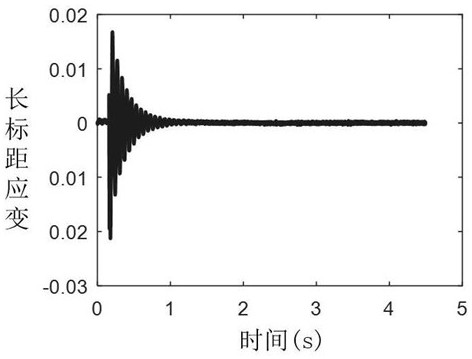

[0063] S1, based on the impact force time history under impact vibration and the response of the long gauge FBG sensor fixed on the structure surface, the structural strain compliance is identified;

[0064] S11, record the impact force and long gauge strain response under shock vibration, and determine the long gauge strain FRFs;

[0065] S12, the basic structural parameters are identified by the complex modulus indicator function method, and the singular value decomposition (SVD) is applied to the long-strain FRFs to obtain:

[0066]

[0067] in and are the left singular vector and the right singular vector respectively, which are the singular value matrix composed of frequency information and damping information; U L is the left singular vector, including the mode shape information of the left nodes of all elements; U R is the mode shape informa...

Embodiment 2

[0111] The difference between this embodiment and Embodiment 1 is that when the structure to be tested is a steel structure, the change in element stiffness can be used as an index for quantitative corrosion, and the amount of corrosion can be directly judged by the stiffness of the structural element obtained from the solution in step S5 ; When the structure to be measured is a reinforced concrete structure, step S6 is also included, according to the nonlinear stage stiffness calculation formula Solve the current reinforcement area and corrosion area of the structure to be tested, and judge the amount of corrosion.

Embodiment 3

[0113] A two-stage strategy for structural corrosion detection systems based on rapid vibration, such as figure 1 As shown, in this embodiment, the system is used for bridge experiments as an example, including a rapid inspection vehicle equipped with an impact device, a data acquisition system and a data analysis system;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com