Method for monitoring damage to a shaft

A damage and deformation technology, applied in the field of monitoring the damage of the shaft, can solve the problem of not directly detecting the damage of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

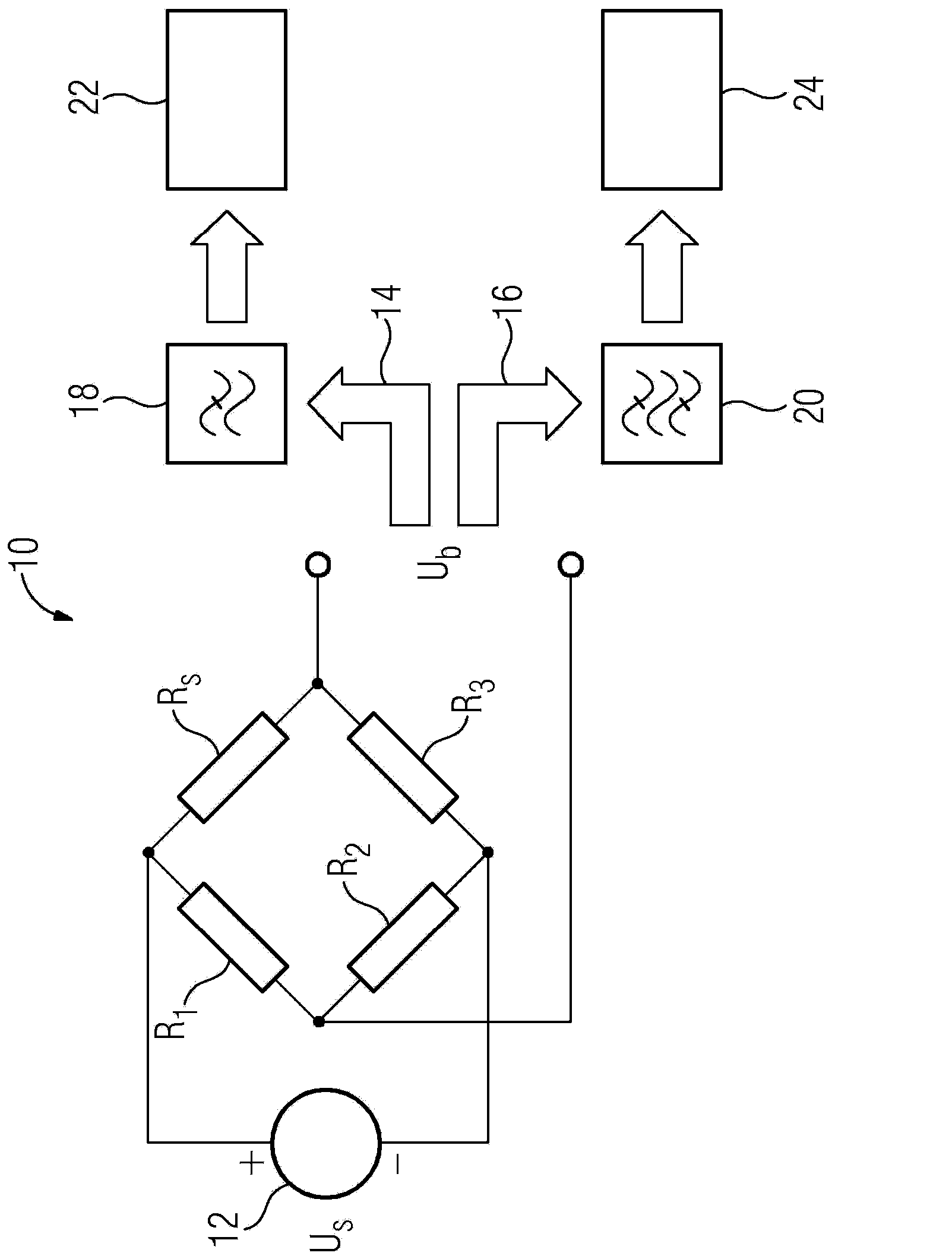

[0024] figure 1 A device 10 for monitoring damage to a shaft is shown. The device 10 includes a strain gauge R S , the strain gauge is shown here as a resistor. Strain gauge R S Together with the other three resistors R1, R2 and R3 are connected according to a Wheatstone bridge. The supply voltage U of the voltage supply system 12 S supplied to the bridge circuit. Strain gauge R S The measurement signal U b The bridge voltage, which can be used as a measuring bridge, is tapped.

[0025] Several strain gauges R can likewise be arranged on axes not shown here S . Strain gauge R S For example, it can be formed as a resistive wire on a foil. Strain gauge R S Can be made of metal or of semiconductor. Strain gauge R S It is preferably mounted on the outer surface of the shaft with a special adhesive. Because of the mechanical deformation of the shaft, the strain gauge R S mechanical deformation. Due to mechanical deformation the strain gauge R S resistance changes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com