Heat exchanging fin group, heat exchanger and air conditioner

A technology of heat exchange fins and fins, which is applied in the field of heat exchangers, can solve the problems of reducing the heat exchange efficiency of the rear fins, and achieve the effects of avoiding processing difficulties, preventing a large reduction, and improving the heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

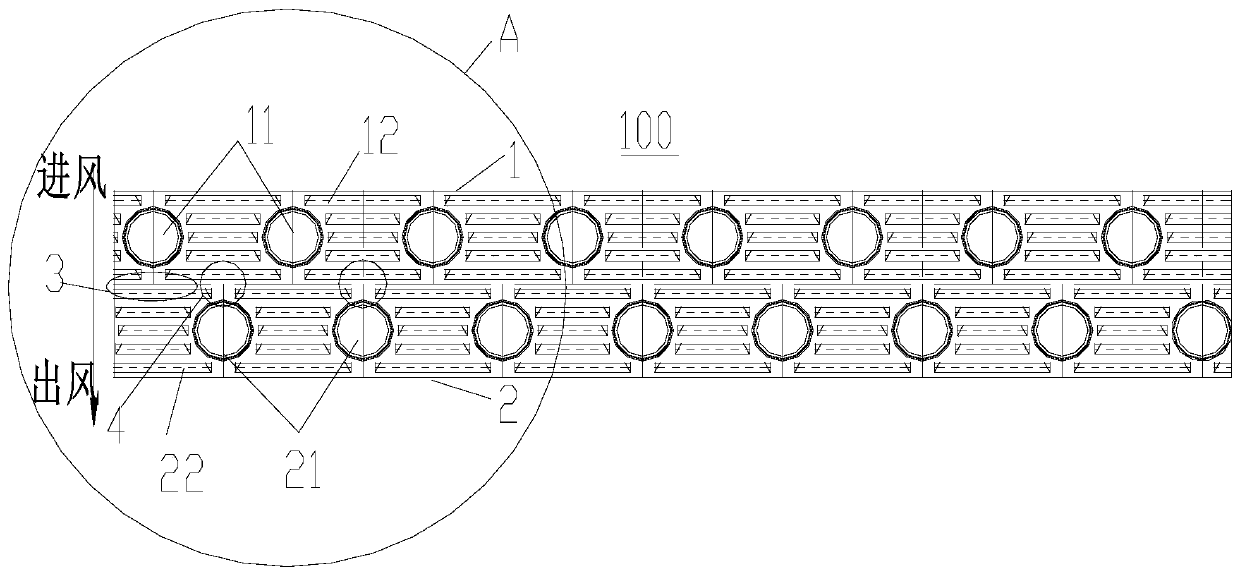

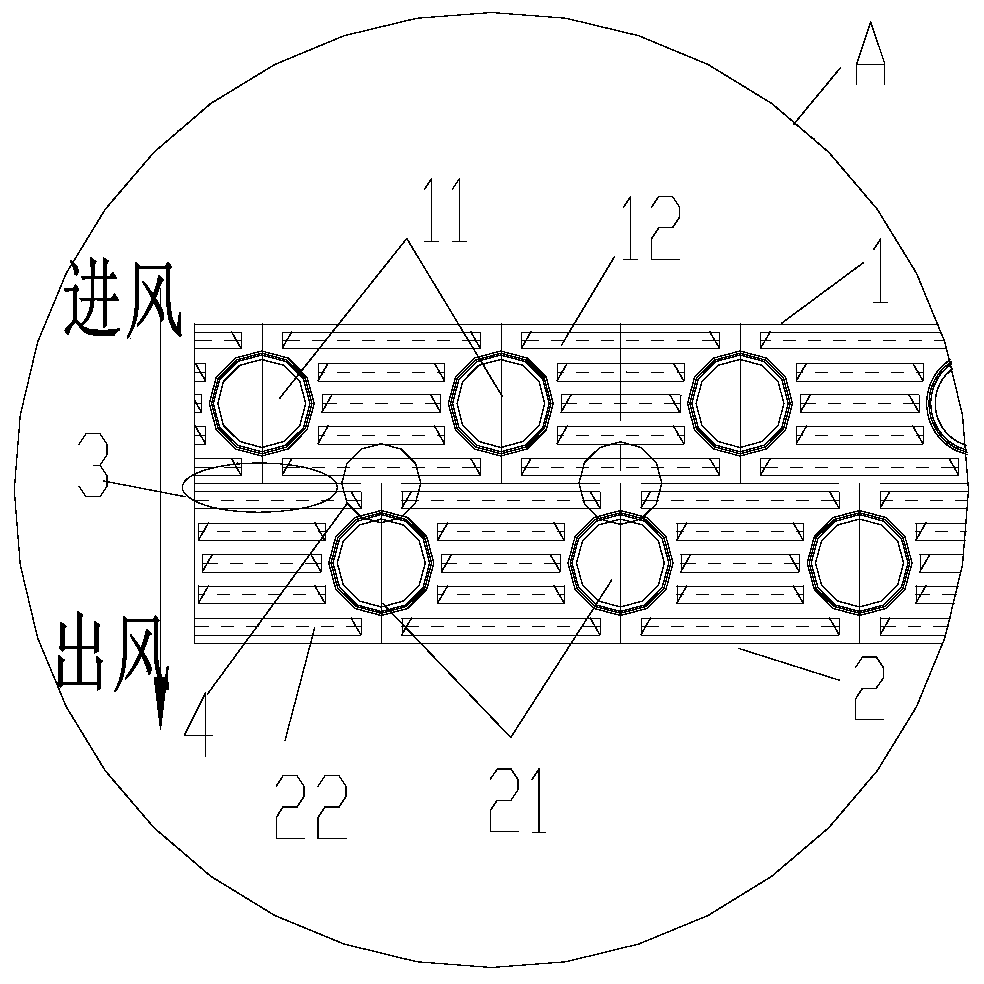

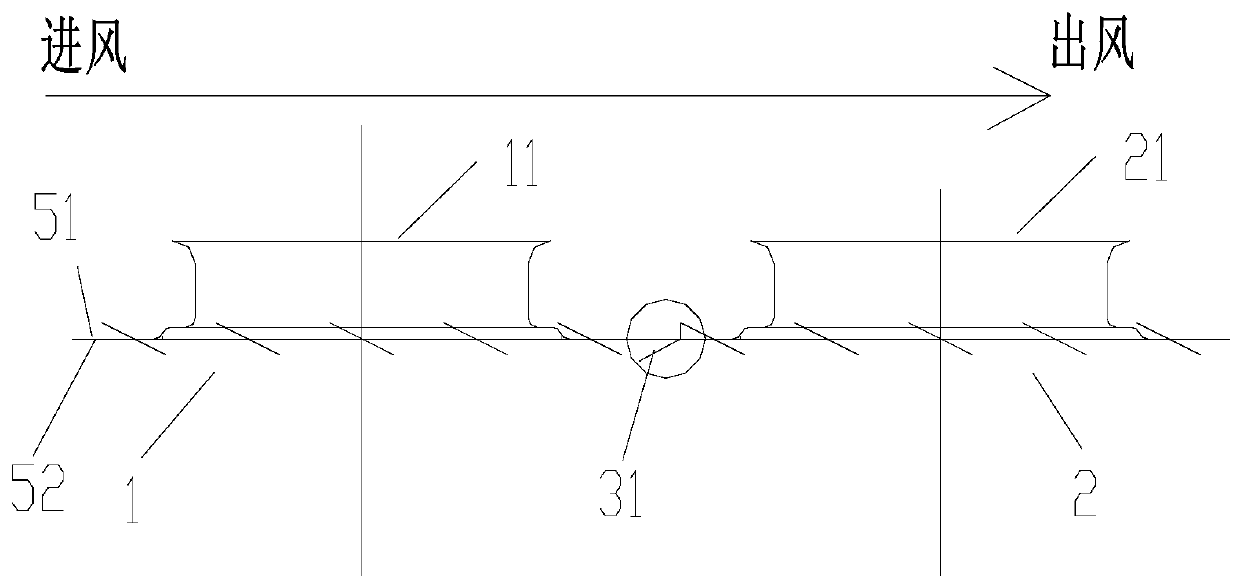

[0024] Such as Figure 1-4 As shown, the present invention provides a heat exchange fin group, which includes:

[0025] The first row of fins 1 and the second row of fins 2, the first row of fins 1 and the second row of fins 2 are arranged in sequence along the airflow direction, and the second row of fins 2 are arranged on the The first row of fins 1 is provided with at least one first pipe hole 11 through which the heat exchange tube passes along the airflow direction, and the second row of fins 2 is provided with There is at least one second tube hole 21 that can accommodate the heat exchange tube. The second tube hole 21 is opposite to the position between the two adjacent first tube holes 11 along the direction of air flow, and extends along The structure between the first row of fins 1 and the second row of fins 2 that is opposite to the first tube hole 11 in the direction of airflow is a structure with a gap 3 (the gap here is disconnected) The structure includes a struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com