An electric heating carburetor

A technology of electric heating and carburizing oil, which is applied in lighting and heating equipment, water heaters, chemical industry, etc. It can solve the problems of easy gelatinization and carbonization of electric heating rods, pollution of the environment by smoke, and pollution of raw materials by carbonized particles, so as to avoid heat exchange efficiency problems, ensure product quality, and avoid the effect of heating and gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

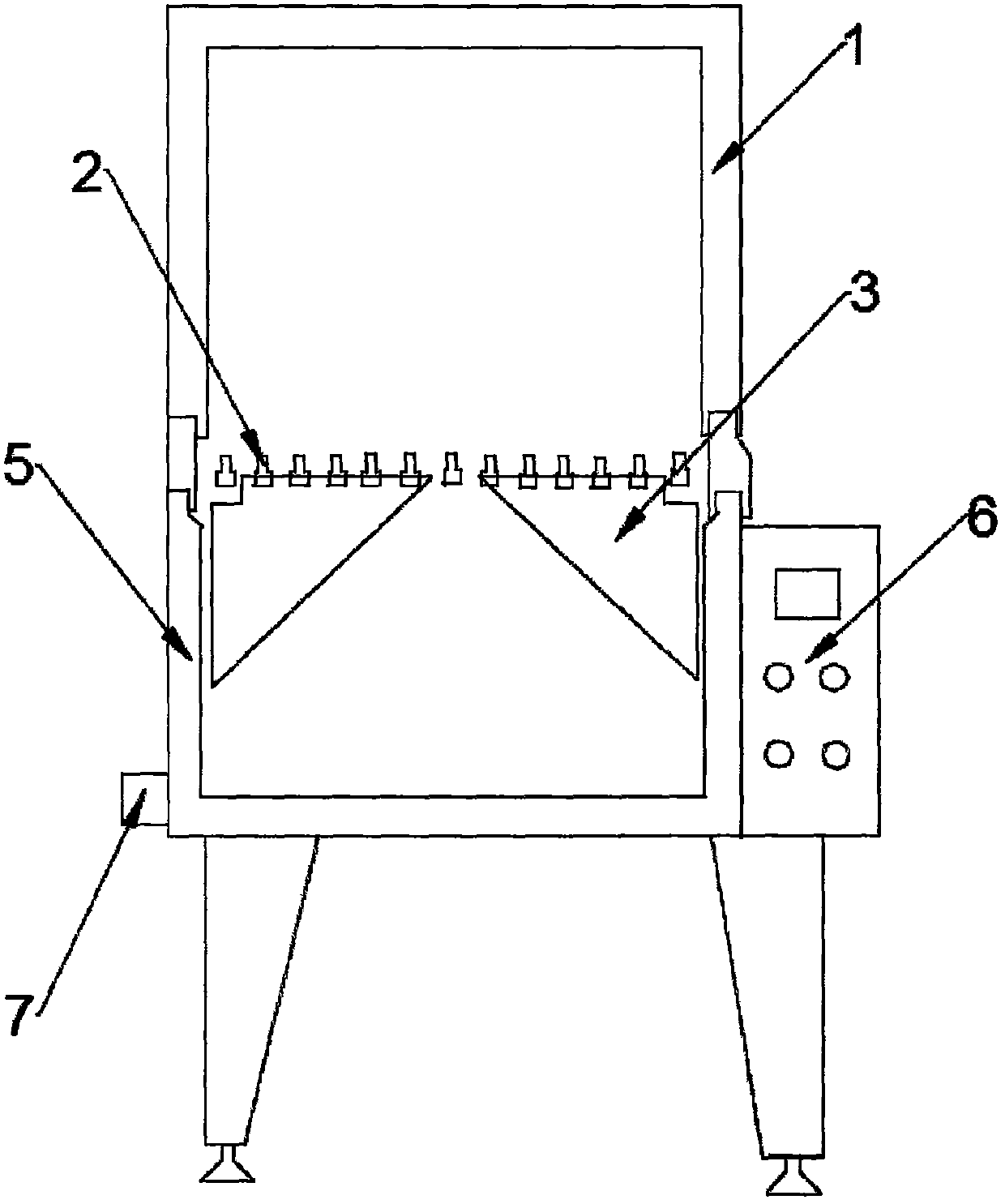

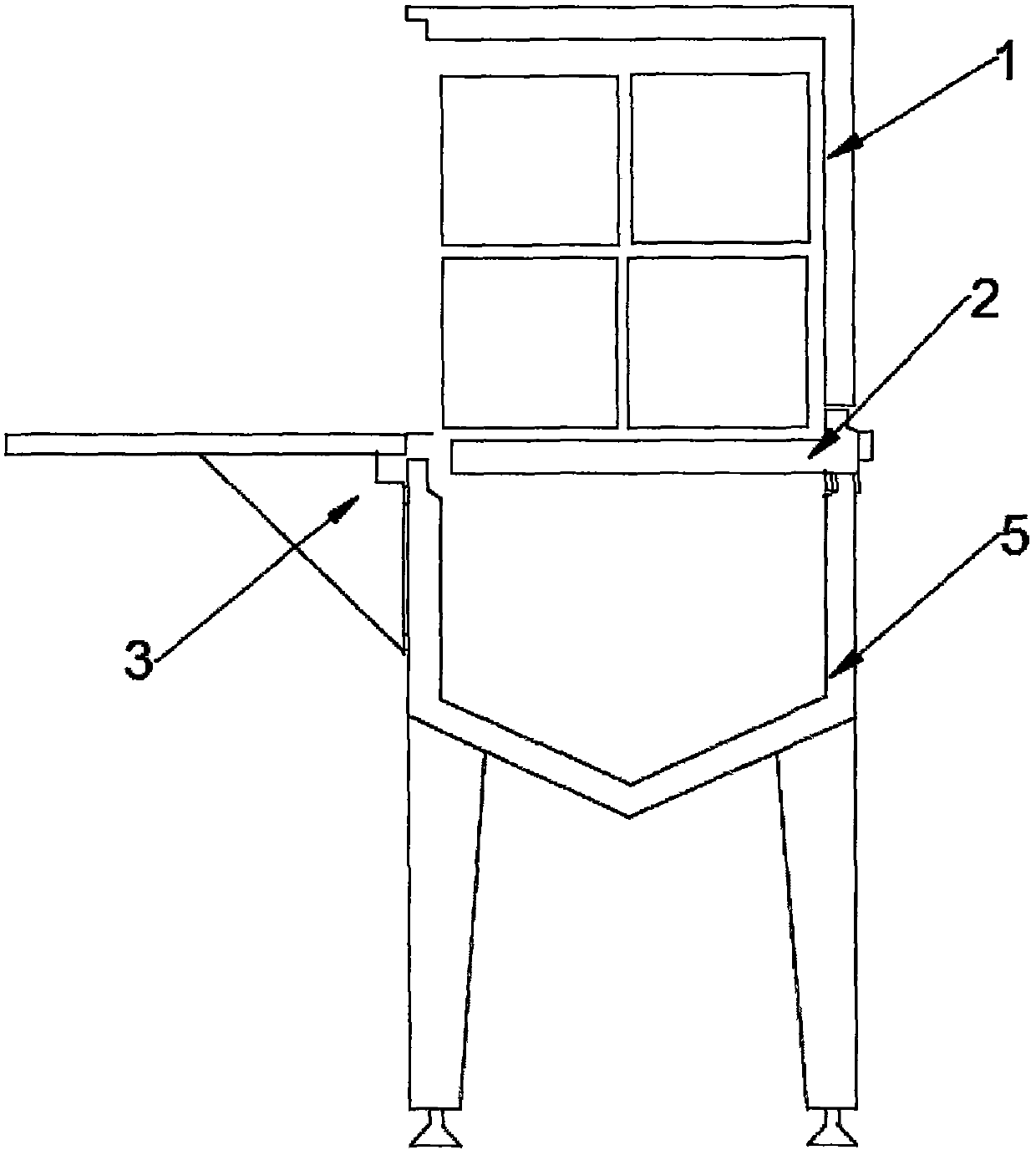

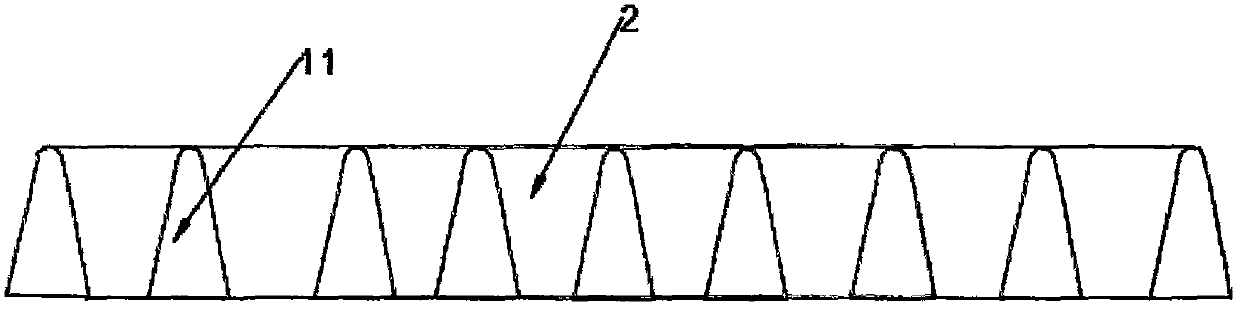

[0019] see Figure 1-5 , a kind of electric heating oil equipment, comprising electric heating insulation storage tank 5, electric heating oil grate 2, heat preservation upper cover 1, folding support frame flip platform door 3, heating unit structure 11 and control box 6, said electric heating oil grate 2 Installed on the upper part of the electric thermal insulation storage tank 5, the thermal insulation upper cover 1 is installed on the upper part of the electric heating oil grate 2, the control box 6 is located on one side of the electric thermal insulation storage tank 5, and the electric heating oil grate 2 is assembled and welded by multiple heating unit structures 11 in parallel The folding support frame flips the platform door 3 and is installed on the upper edge of the front end of the electric thermal insulation storage tank 5. The heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com