A disinfecting machine and a control method for the disinfecting machine

A technology of disinfecting machine and control module, applied in the field of sanitation and epidemic prevention, can solve problems such as dead ends of operations, inability to meet various needs of users, and inability to adjust, and achieves the effect of good epidemic prevention effect, wide coverage, and flexible and diverse methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

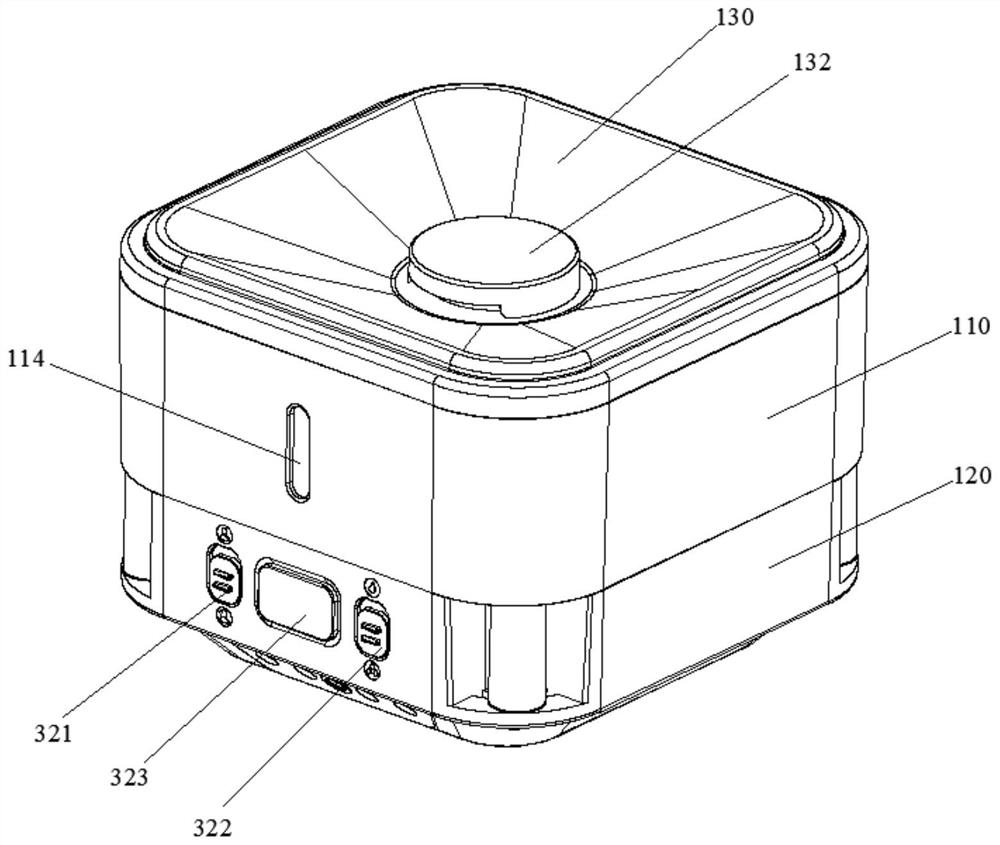

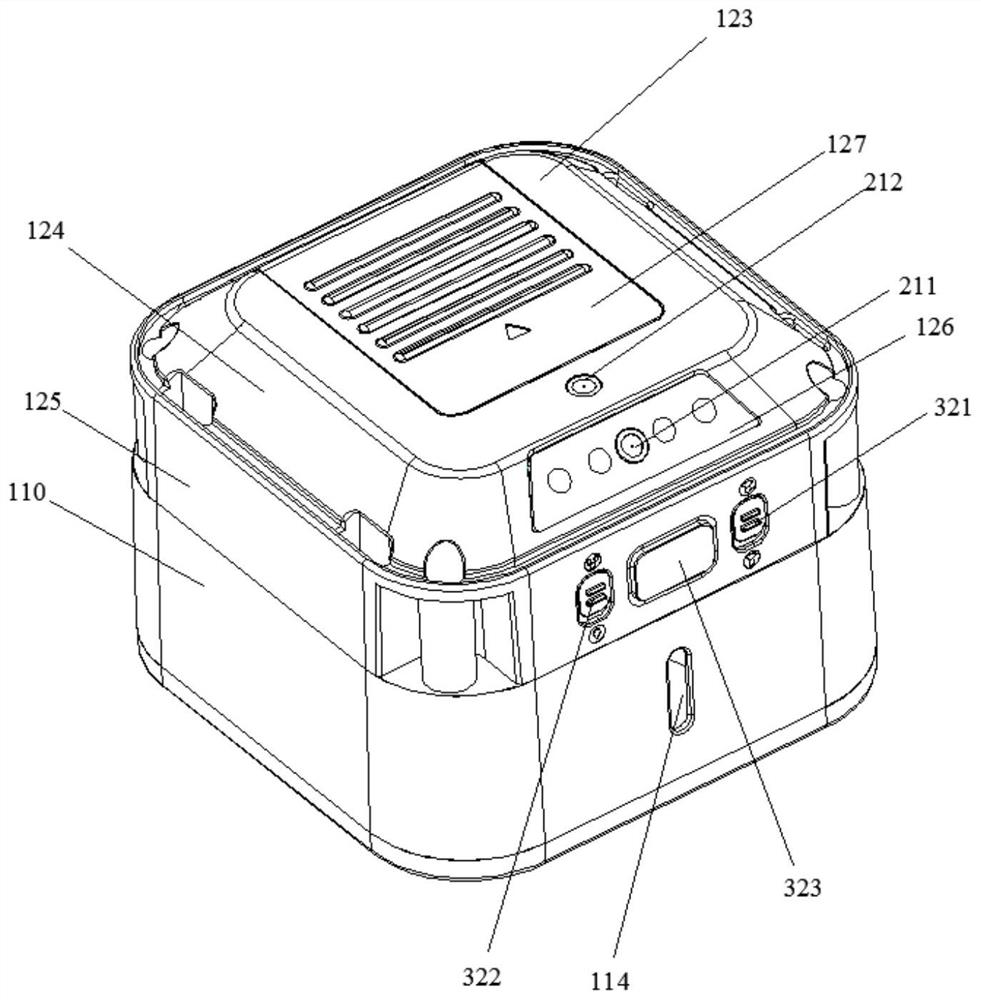

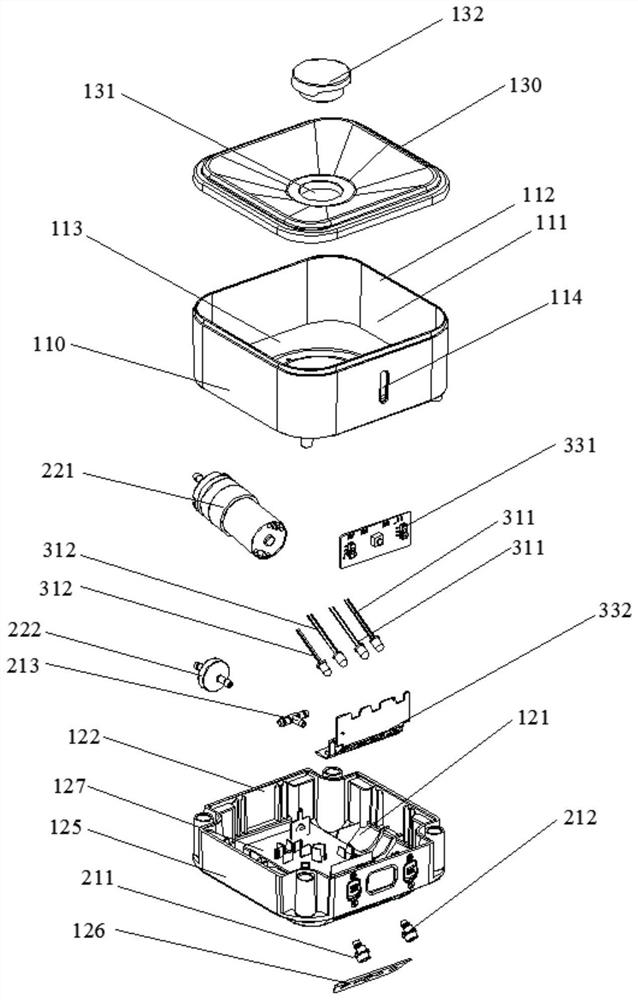

[0024] as Figures 1 through 3 As shown, the sanitize machine of the present application, including a housing, a spraying mechanism, a testing mechanism and a power module.

[0025] Housing, provided with a first chamber 111 and a second chamber 121, the first chamber 111 for storing liquids;

[0026] Spraying mechanism, including drive components and spray components. The drive assembly is disposed in the second chamber 121 for driving the spraying assembly, the spraying component comprises a first nozzle 211 and a second nozzle 212, the first nozzle 211 and the second nozzle 212 having different spray angles, the first nozzle 211 and the second nozzle 212 are respectively disposed on the surface of the second chamber, and the first nozzle 211 and the second nozzle 212 are connected to the first chamber 111, respectively;

[0027] Detection mechanism, including sensors, switch components and control modules, switch components for setting the spraying method of the spraying compone...

Embodiment approach

[0039] as Figure 4 As shown, the present application for an embodiment of the control method of the sanitize machine in Example I, one embodiment thereof, comprising the following steps:

[0040] Step 402: The control module acquires a first signal transmitted by the switching assembly and a second signal transmitted by the sensor, the first signal comprises a manned mode or unmanned mode, a small amount of spray mode or a large number of spray modes, a press switch touched or the press switch is not touched; the second signal comprises a close detection mode and a long-distance detection mode.

[0041] Step 404: The control module identifies the first signal and the second signal, and drives the first and second sprinklers according to the first signal and the second signal control driver component to spray the liquid according to a preset pattern.

[0042] Further, in one embodiment, the control module may optionally be an MCU, the drive assembly may be selected with a water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com