Heat dissipating fin pasting device for mobile phone assembly

A technology of sticking device and heat sink, applied in workpiece clamping devices, hand-held tools, mechanical equipment, etc., can solve the problems of slow processing, affecting processing efficiency, inconvenient operation of tweezers, etc., so as to improve processing efficiency and facilitate operation. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

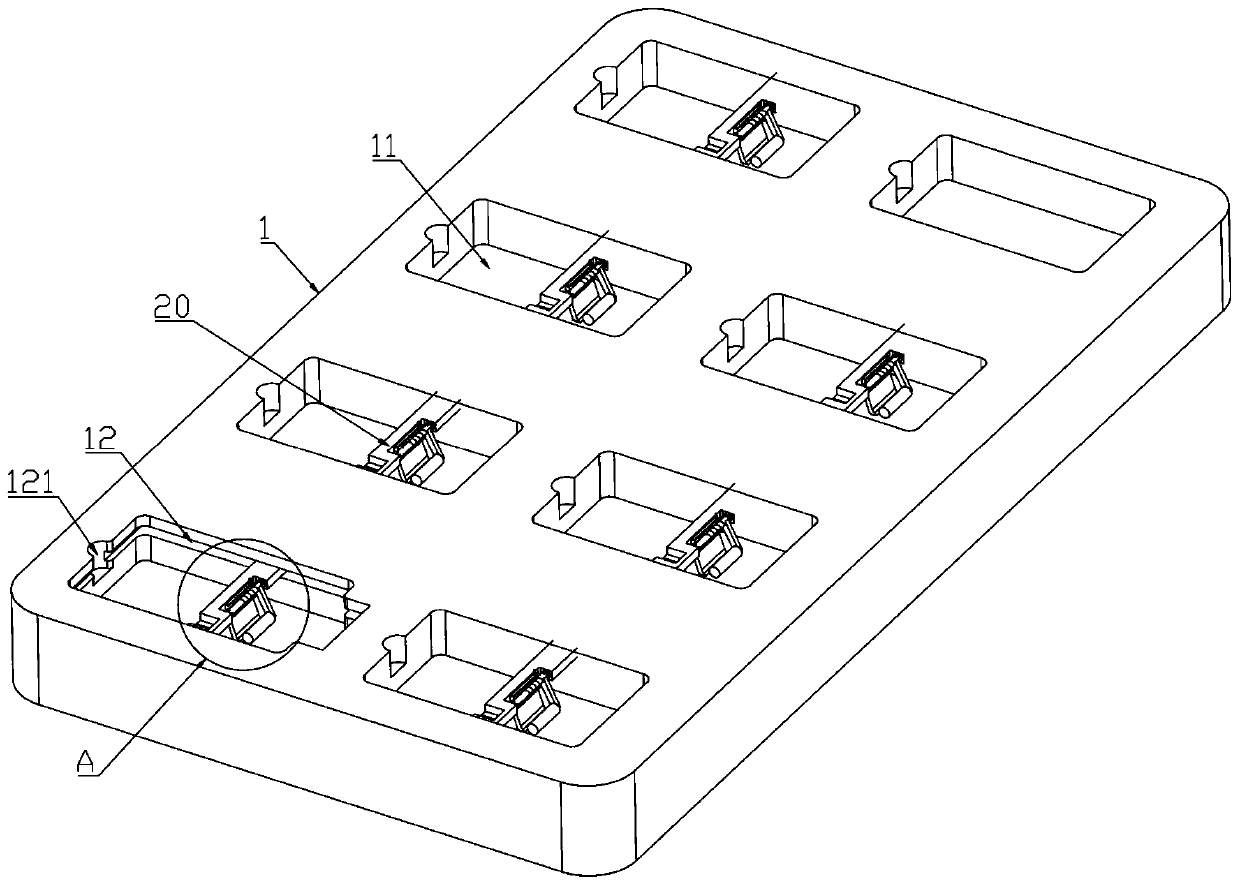

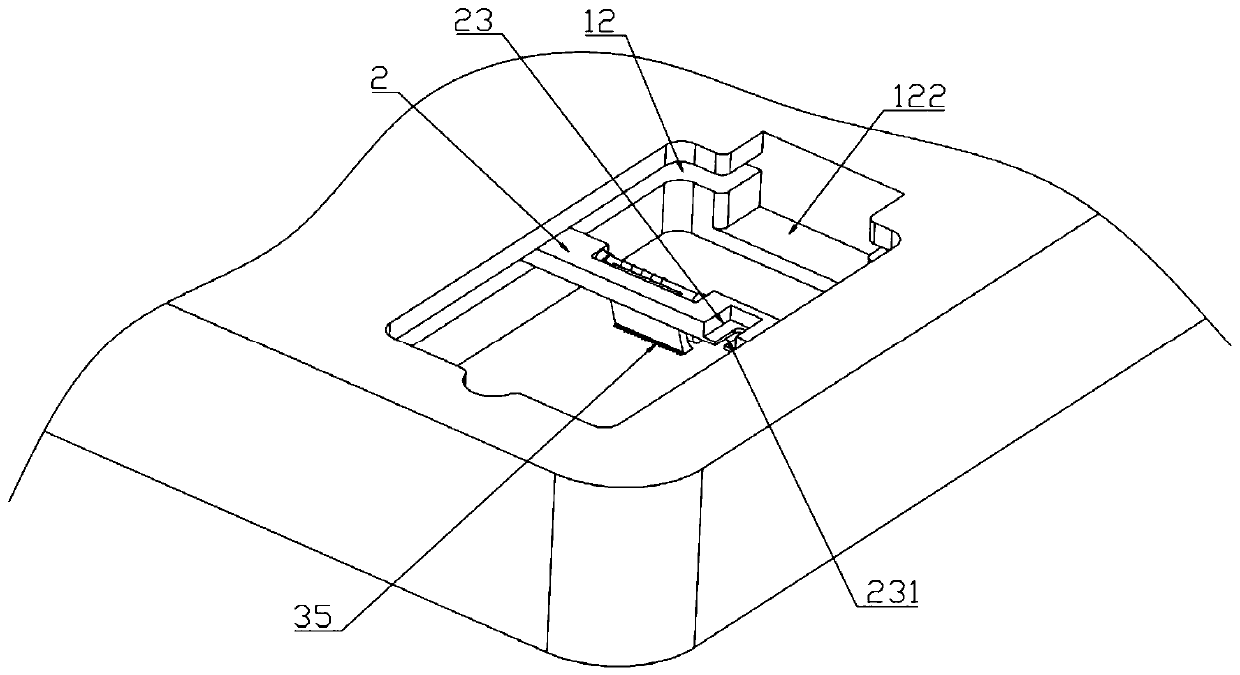

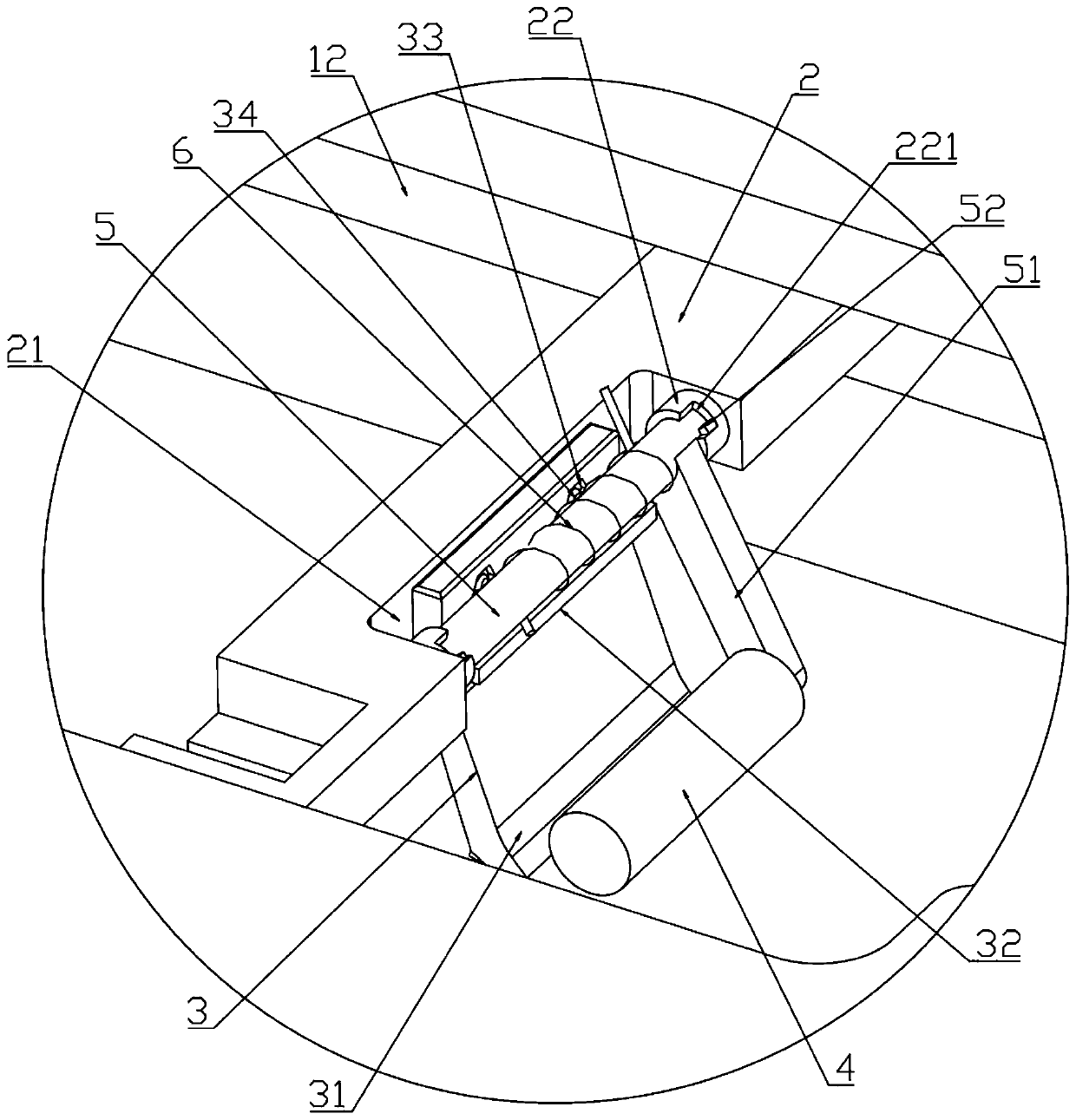

[0024] Such as Figure 1-3 As shown, the present embodiment provides a heat sink pasting device for mobile phone assembly, including a module fixing plate 1, and the module fixing plate 1 is provided with several positioning grooves 11 for fixing the TP module; On the positioning groove 11, a patch assembly 20 is arranged above the TP module, and the patch assembly 20 is slidably connected with the positioning groove 11; The tearing film scraper 3 is located at the front side of the sliding direction of the patch assembly 20 during processing, and the pressing roller 4 is against the TP module, and always has a movement tendency to move towards the TP module. When working, place the TP module in the positioning groove 11, and then push the patch assembly 20 along the length direction of the TP modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com