Three-dimensional multi-layer cable box

A multi-layer wire and three-dimensional technology, applied in the direction of the cable suspension device, etc., can solve the problems of messy wire order, inability to flexibly adjust the position and angle of the winding column according to the demand, and the limited space for winding and routing. To achieve the effect of increasing the winding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

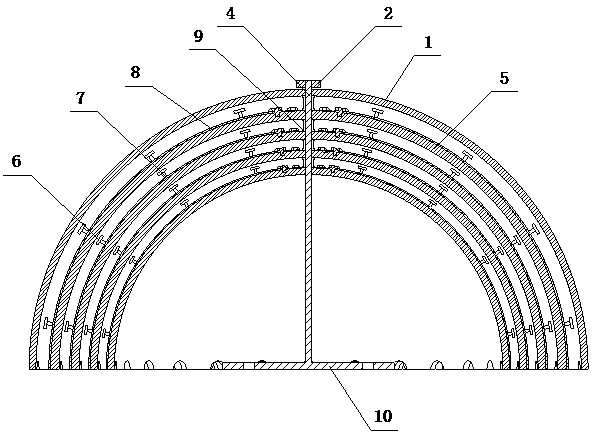

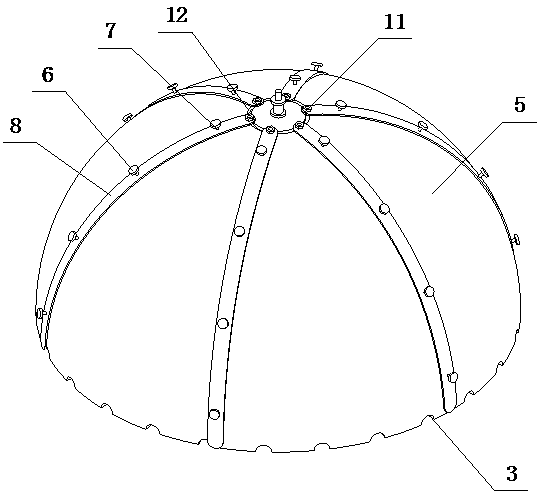

[0022] The difference between this embodiment and Embodiment 1 is that: the protective cover (1) is provided with a diversion groove (13); when in use, it can improve the rain-proof and diversion effect;

[0023] The fixed base (10) is designed as a curved clamping plate, which can be clamped on the utility pole for installation, and is more convenient to use;

[0024] The wire winding post (7) is provided with a clamping groove, and the wire pressing cap (6) is equipped with a design of rubber teeth, which can better clamp the wire and make the wire winding more firm;

[0025] The bottom of the fixed base (10) is designed with an anti-skid pad, which can make the device more stable and avoid sliding;

[0026] The fixed stud (4) is screwed with a limit nut, and the limit nut is placed under the innermost arc cover (5), which can support and fix the arc cover (5) from below , to prevent the innermost arc cover (5) from sliding down;

[0027] The bottom of the protective cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com