Inchworm biomimetic structure and manufacturing process based on magnetically driven flexible thin film actuator

A flexible film and manufacturing process technology, applied in the field of bionic structures and manufacturing processes of inchworms, can solve the problems of high driving voltage, slow response, and reduced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

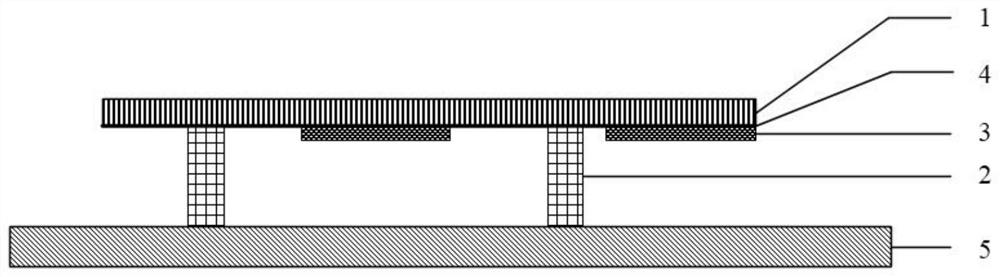

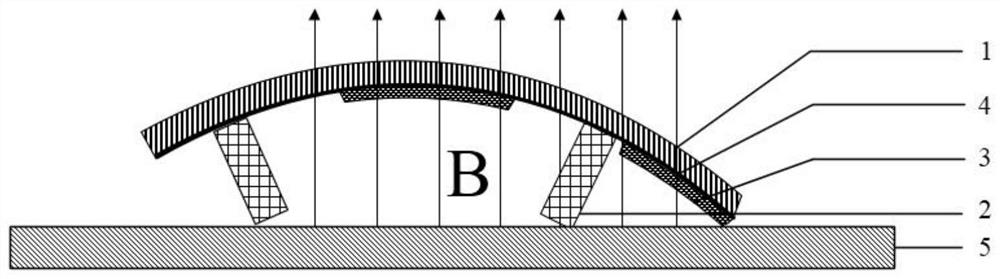

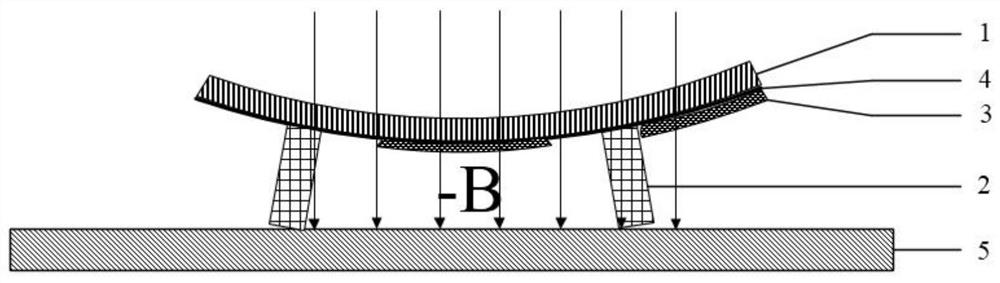

[0032] Such as figure 1 As shown, a magnetically driven biomimetic inchworm structure based on a magnetically driven flexible thin film driver includes a top layer of silicone membrane 1 with a certain thickness, a foot structure 2 is provided under the silicone membrane 1, and a silicone membrane 1 is provided under the head and abdomen. There is a magnetically driven flexible film driver 3, the magnetically driven flexible film driver 3, and the foot structure 2 are bonded to the silicone mold 1 through an adhesive material 4, and the magnetic poles of the magnetically driven flexible film driver 3 on the head and abdomen are opposite.

[0033] The silica gel film 1 adopts elastomers such as silica gel or polyurethane, and the foot structure 2 adopts elastomers such as silica gel or polyurethane; the adhesive material 4 adopts silica gel adhesive or silica gel glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com