A negative pressure-assisted bionic dry adhesion pick-up structure and its preparation process

A preparation process and dry adhesion technology, which is applied in the field of bionic dry adhesion pick-up structure and preparation process, can solve the problems of not showing adhesion characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

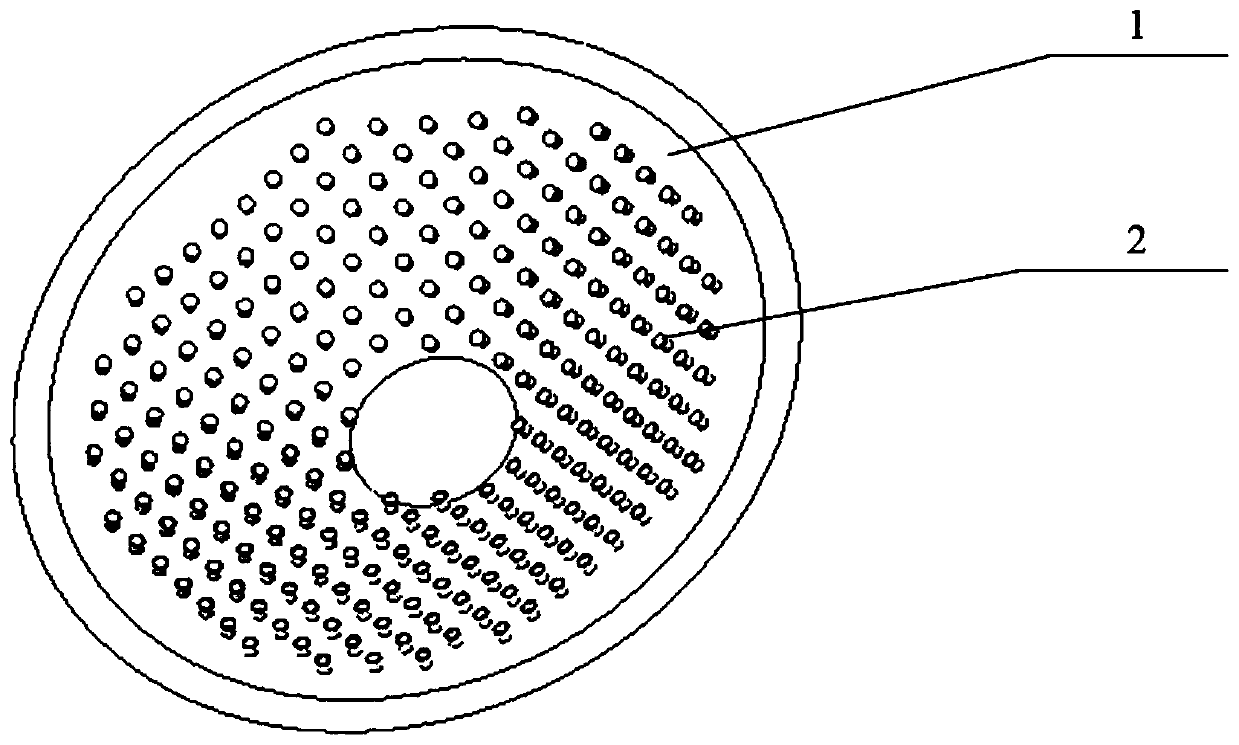

[0026] Referring to Figure 1, a negative pressure-assisted bionic dry adhesion pick-up structure is a sucker-shaped elastic body 1 as a whole. The size of the elastic body 1 is on the order of millimeters to centimeters, and a layer of imitation gecko mushroom is bonded on the surface of the elastic body 1. The size of a single gecko-like dry-adhesive elastic body structure 2 is at the micron level.

[0027] The elastic body 1 and the gecko-like mushroom-like dry adhesive elastic body structure 2 are all made of silicon rubber or polyurethane.

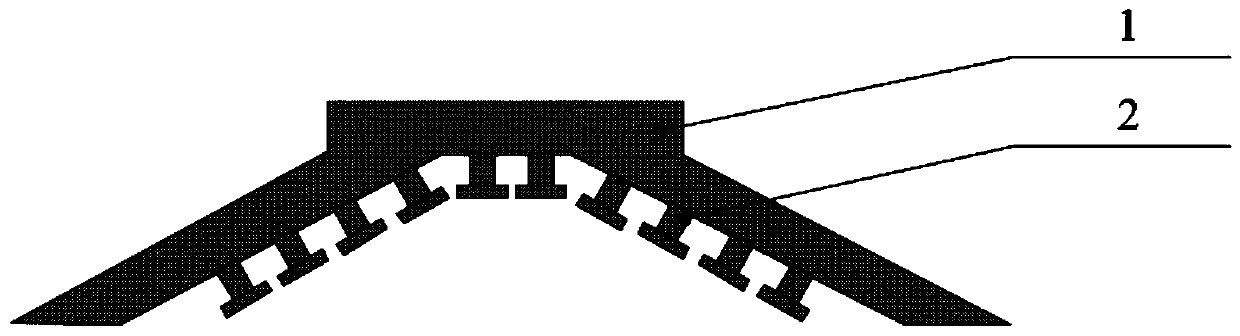

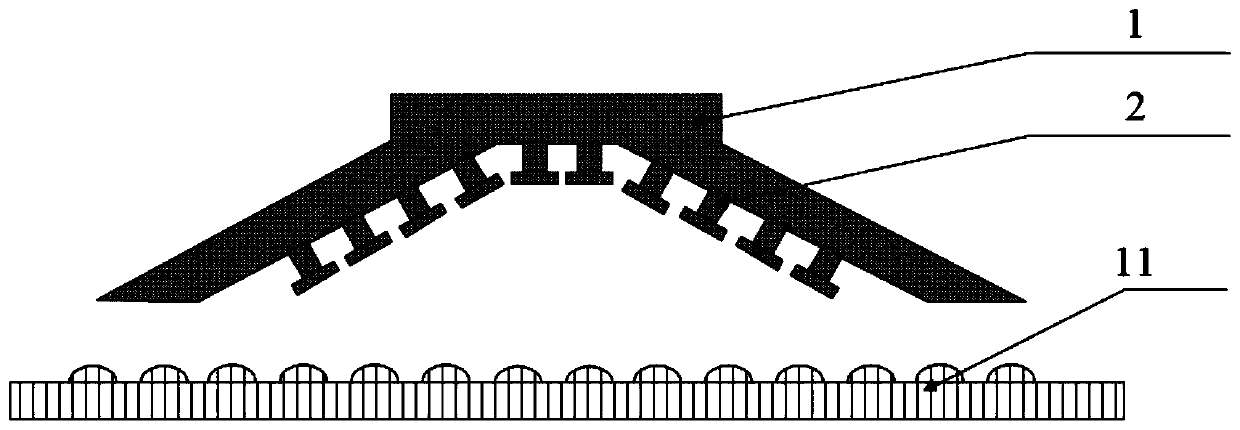

[0028] refer to diagram 2-1 , Figure 2-2 , when the roughness of the surface 11 of the object is at the micron level, such as the surface of ground glass and gallium nitride, since the scale of the gecko-like mushroom-like dry-adhesive elastomer structure 2 is in the same order of magnitude, the adhesion effect is not obv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com