Bionic inchworm structure based on liquid crystal elastic polymer and manufacturing process thereof

A liquid crystal elasticity, polymer technology, applied in the field of inchworm bionic structure and manufacturing process, can solve the problems of reduced flexibility, limited deformation size, small deformation, etc., to achieve the effect of accurate and controllable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

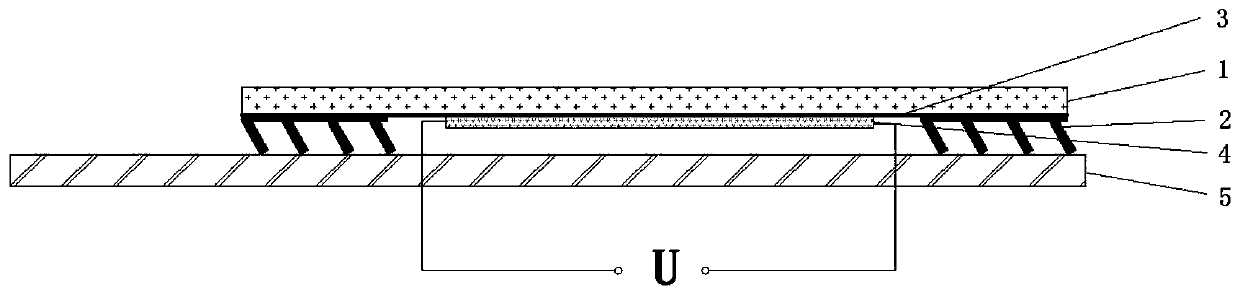

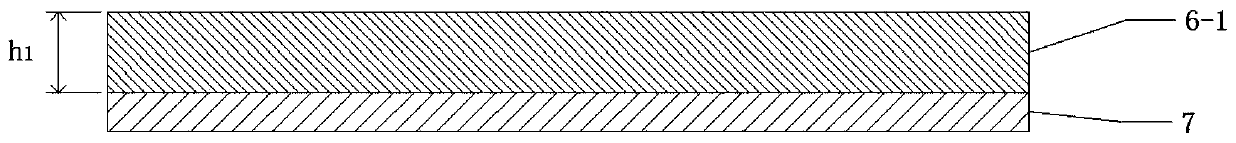

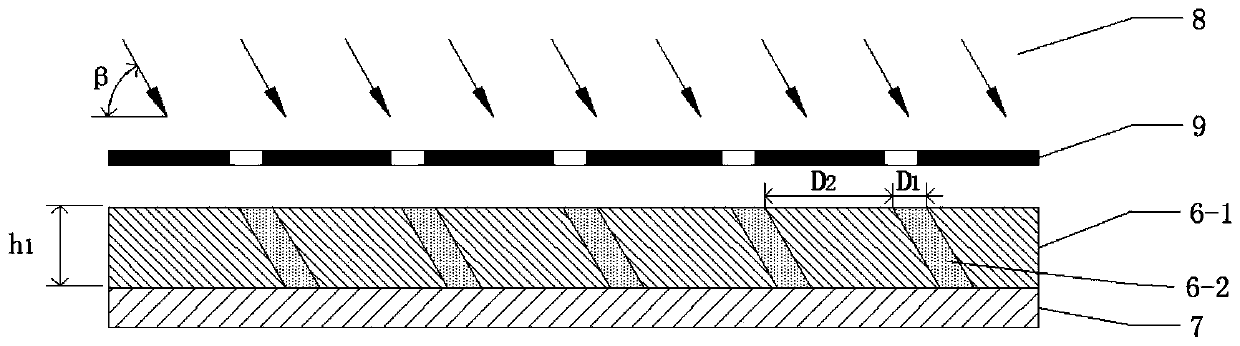

[0027] An electrically actuated biomimetic inchworm structure based on liquid crystal elastic polymer, the top layer is a silicone film 1 with a certain thickness, the oblique columnar array structure 2 below and the liquid crystal elastic polymer 4 are bonded to the top layer of silicone film 1 through an adhesive material 3 .

[0028] The oblique columnar array structure adopts silica gel or polyurethane; the adhesive material adopts silica gel adhesive or silica gel glue; the described liquid crystal elastic polymer adopts liquid crystal elastic polymer LCE doped with carbon nanotubes or graphene.

[0029] When the voltage U applied across the liquid crystal elastic polymer 4 is 0, the liquid crystal elastic polymer 4 does not deform, such as figure 1 As shown; when the voltage U applied to both ends of the liquid crystal elastic polymer 4 is not 0, the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com