A kind of red dye and its preparation method and application

A red dye and dye technology, applied in the field of red dye and its preparation, can solve the problems of poor dyeing depth and poor color matching of nylon/cotton, and achieve the effects of reducing sewage discharge, saving dyeing time, and good color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] According to the content ratio of each component whose dye number is 1 in Table 3, accurately weigh 55 grams of A1, 25 grams of B1, 15 grams of sodium sulfate, and 5 grams of MF, and mix well to obtain the red dye of the present invention.

[0075] The amount of each component in Table 3 is represented by the percentage immediately following it, and the percentage refers to the mass percentage of the quality of each component in the total mass of the dye; The compounds are described in Table 1, and the compounds indicated by the B1-B5 numbers of component B are described in Table 2.

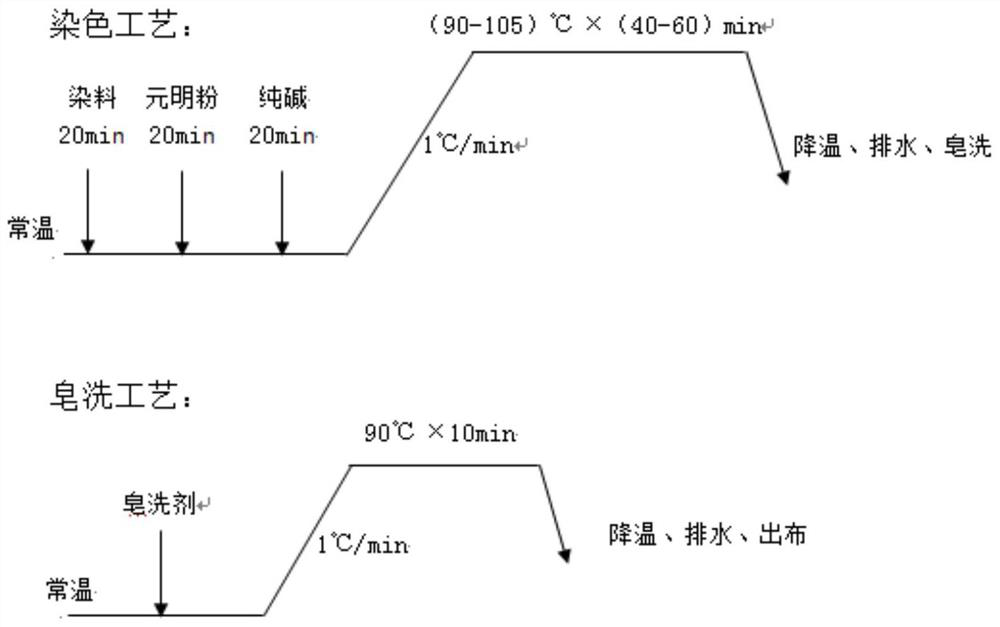

[0076] Accurately weigh 10 grams of nylon / cotton knitted fabric (the mass ratio of cotton is 70%, and the mass ratio of nylon is 30%) according to the dye consumption of 2% o.w.f, and accurately weigh 0.2 grams of the dyestuff in the present embodiment. The dyeing bath ratio is 1:10, according to figure 1 Dyeing is carried out in the dyeing and finishing process, wherein the consumption ...

Embodiment 2-10

[0078] According to the preparation method of Example 1, with reference to the ratio of each component in Table 3, corresponding dyes with dye numbers 2-10 were prepared respectively. With reference to the dyeing and finishing process in Example 1, corresponding nylon-cotton dyed fabrics can be obtained respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com