High-speed pattern forming machine

A flower grabbing machine, high-speed technology, applied in the direction of baking, dough forming and cutting equipment, dough processing, etc., can solve the problems of unstable product quality, rough scratches, top repairing mechanism structure, high labor intensity, etc., to achieve food The pattern is uniform, clear and beautiful, which is convenient for later maintenance and reduces labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

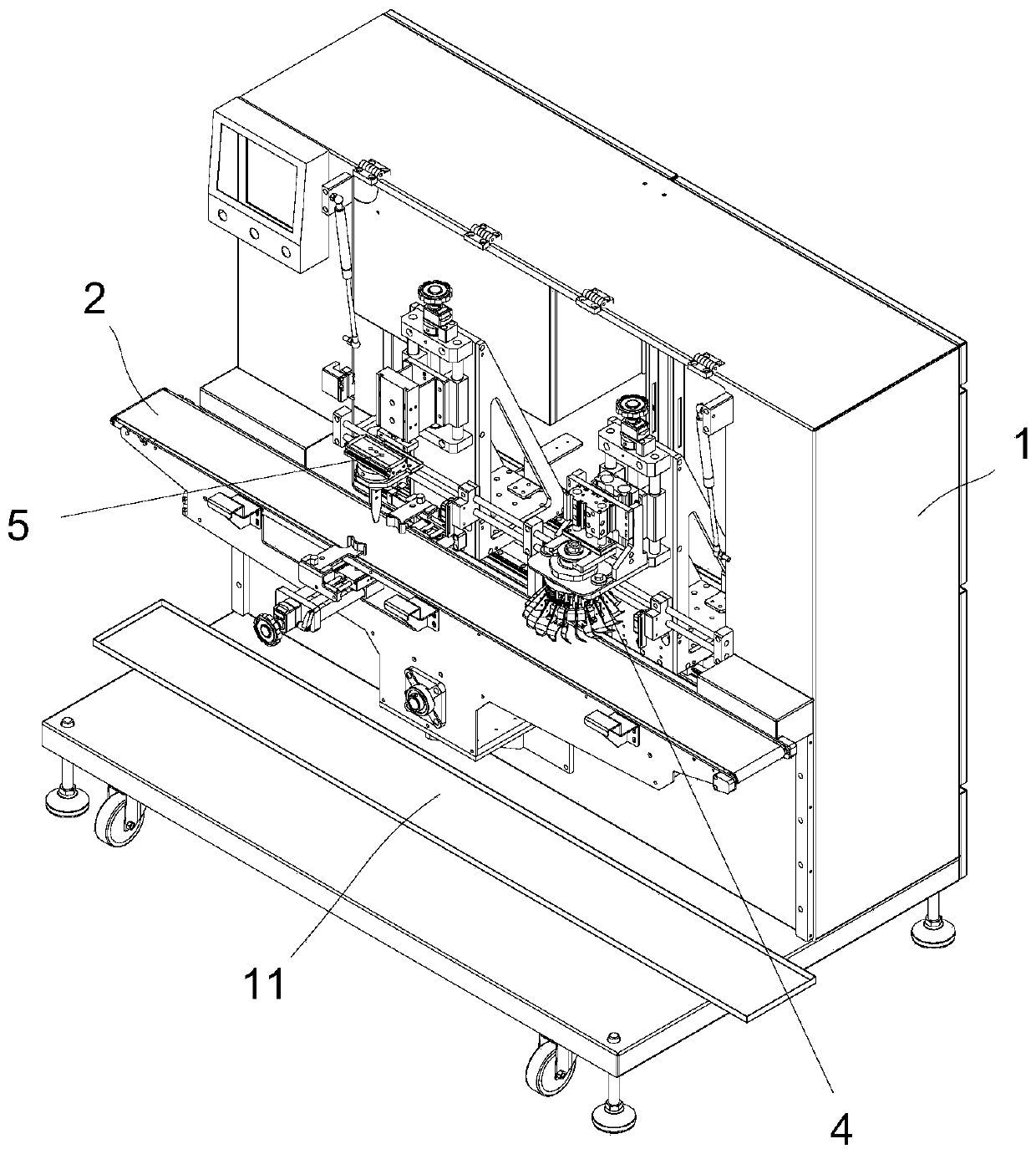

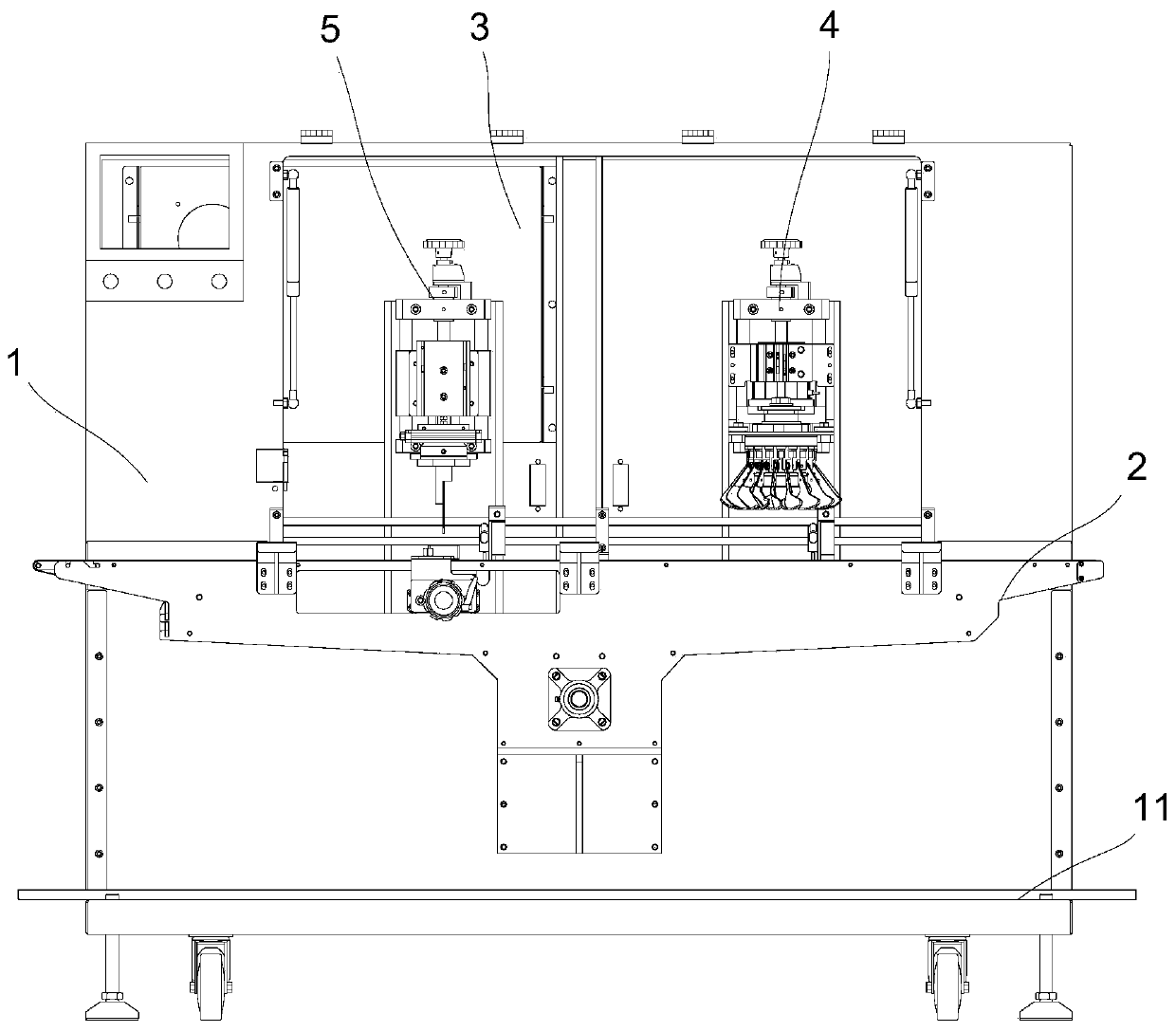

[0052] Such as figure 1 , figure 2 As shown, a high-speed flower grabbing machine includes a body 1 and a conveying line 2, and also includes a follower module 3 arranged on the body 1, and the follower module 3 is fixed on the follower module 3. Scratching module 4 and roof repairing module 5, described scratching module 4 carries out scratching action on the food on the conveying line 2, and described roof repairing module 5 carries out roof trimming on the food on conveying line 2 action.

[0053] A powder receiving tray 11 is arranged below the body 1 .

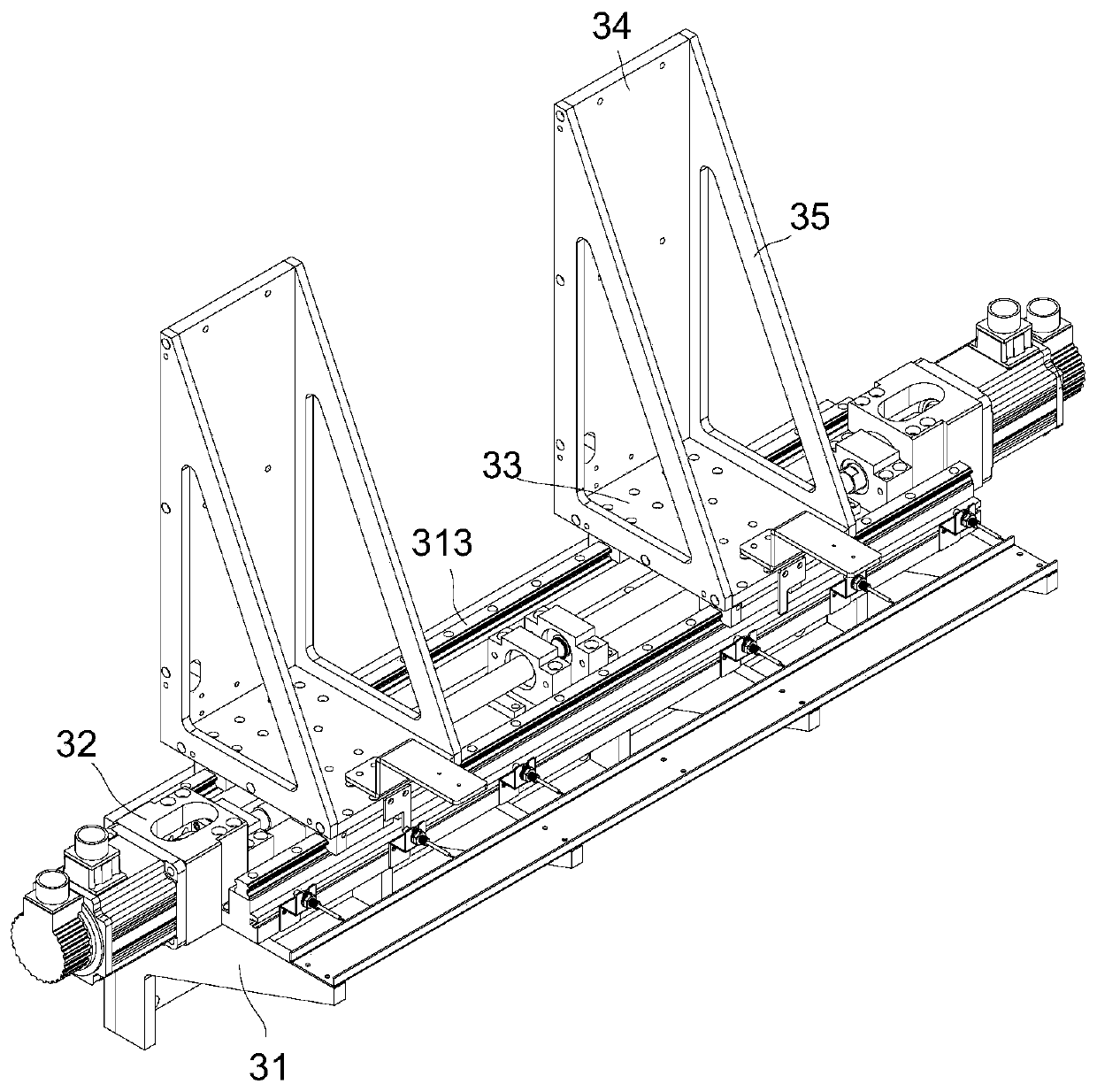

[0054] Such as image 3 , Figure 4 As shown, following the module 3, it includes a support base 31, a linear slide motor 32, a slide base 33 and a riser 34. There are two linear slide motors 32, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com