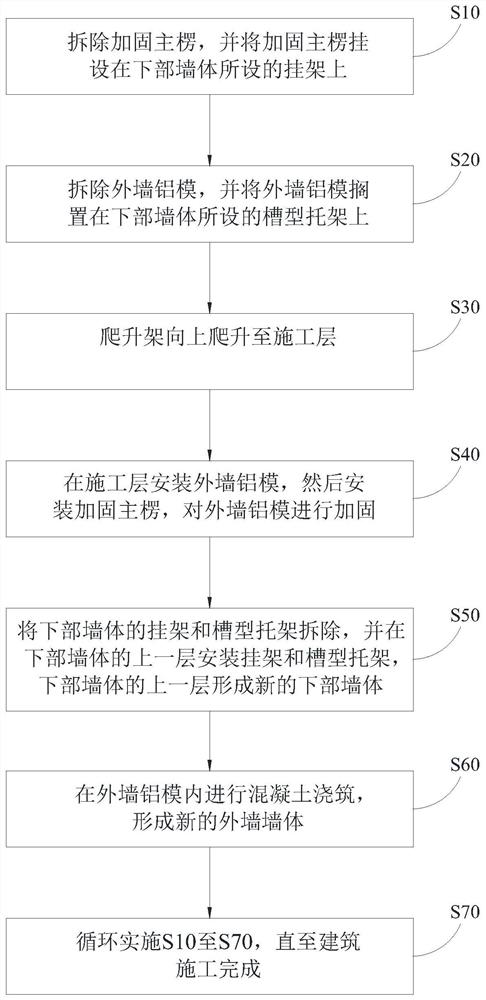

The Construction Method of Demolition and Centralized Placement of Exterior Wall Aluminum Formwork

A construction method and aluminum formwork technology, applied in the field of material stacking, can solve the problems of high safety hazards and achieve the effect of low safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

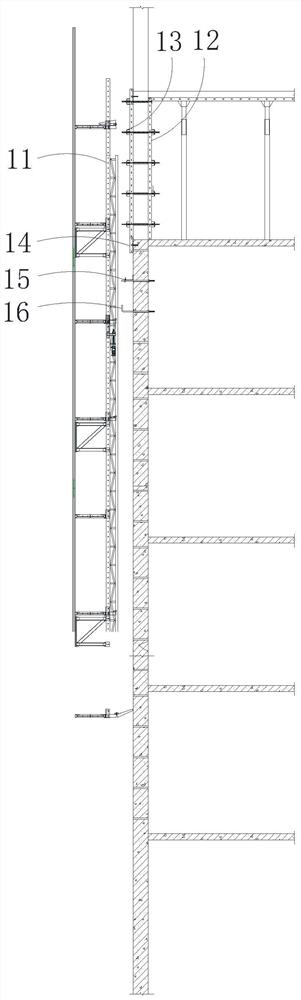

Embodiment 1

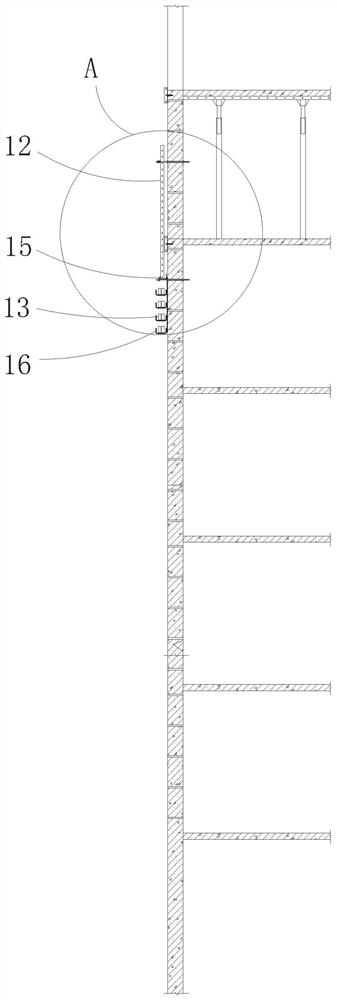

[0071] In the first embodiment, the suspension ring of the suspension rod 161 is hung on the first connecting rod 153, the U-shaped groove 151 is placed on the first connection rod 153, and abuts against the suspension ring of the suspension rod 161, and the U-shaped groove 151 passes through The clamping plate 152 is abutted and fixed, so as to simultaneously fix the U-shaped groove 151 and the suspension rod 161 .

[0072] In this way, in step S50, the cable 154 and the third connecting rod 155 are first disassembled, then the clamping plate 152 is loosened, the U-shaped groove 151 is disassembled, and then the suspension rod 161 and the first connecting rod 153 are dismantled in sequence. , in the installation process, first the first connecting rod 153 is set on the lower wall, then the suspension rod 161 is hung on the first connecting rod 153, and then the U-shaped groove 151 is fixed by the clamping plate 152, and finally The cable 154 and the third connecting rod 155 a...

Embodiment 2

[0073] In the second embodiment, the reinforced main flute 13 is directly hung in the gap between the clamping plate 152 and the U-shaped groove 151 by a sling.

[0074] Like this, in step S50, at first the cable 154 and the third connecting rod 155 are disassembled, then the locking plate 152 is loosened, the U-shaped groove 151 is disassembled, and the first connecting rod 153 is removed. Firstly, the first connecting rod 153 is set on the lower wall, then the U-shaped groove 151 is fixed by the locking plate 152, and finally the cable 154 and the third connecting rod 155 are installed.

[0075] Of course, in other embodiments, the first connecting rod 153 and the second connecting rod 163 may also have different structures, which will not be repeated here.

[0076] Please refer to figure 1 , in an embodiment of the present invention, after step S40:

[0077]The K board 14 of the lower body of wall is removed, and the K board 14 is installed on the top of the construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com