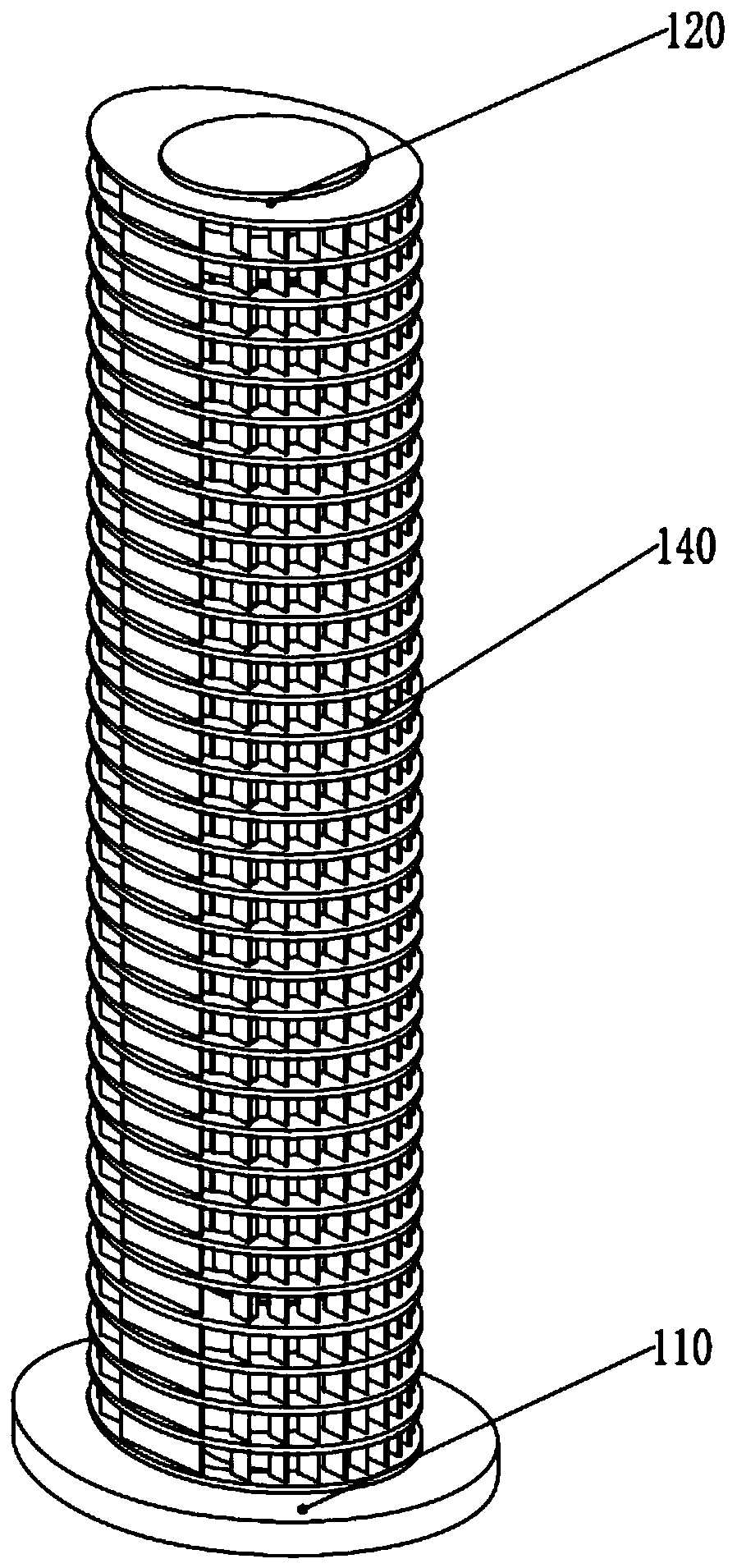

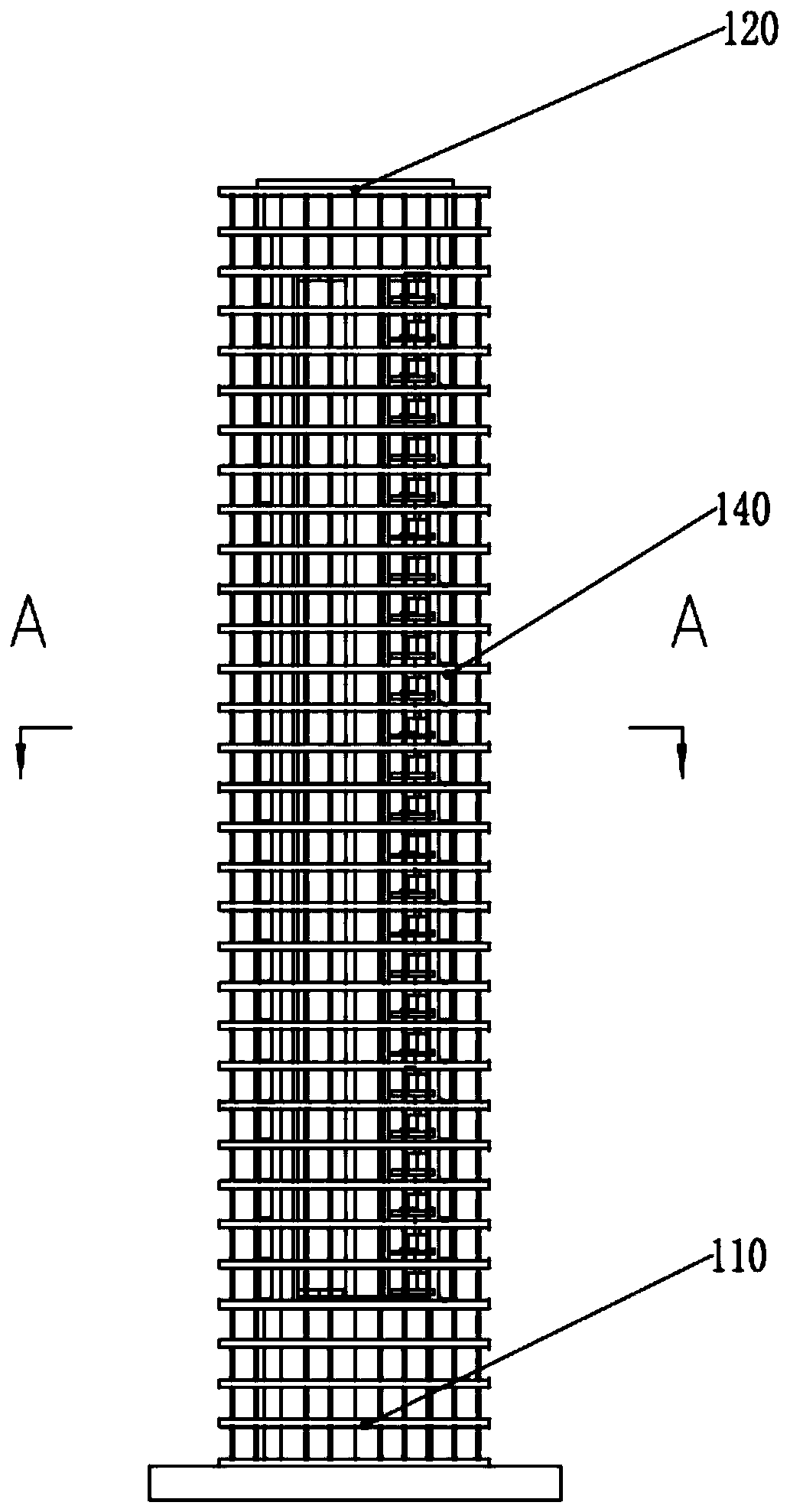

Driving mechanism and air outlet equipment applying same

A driving mechanism, air inlet and outlet technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of adjustment of blowing parameters, low blowing comfort, inability to change the outlet and direction, etc. Variety of states, good user experience, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

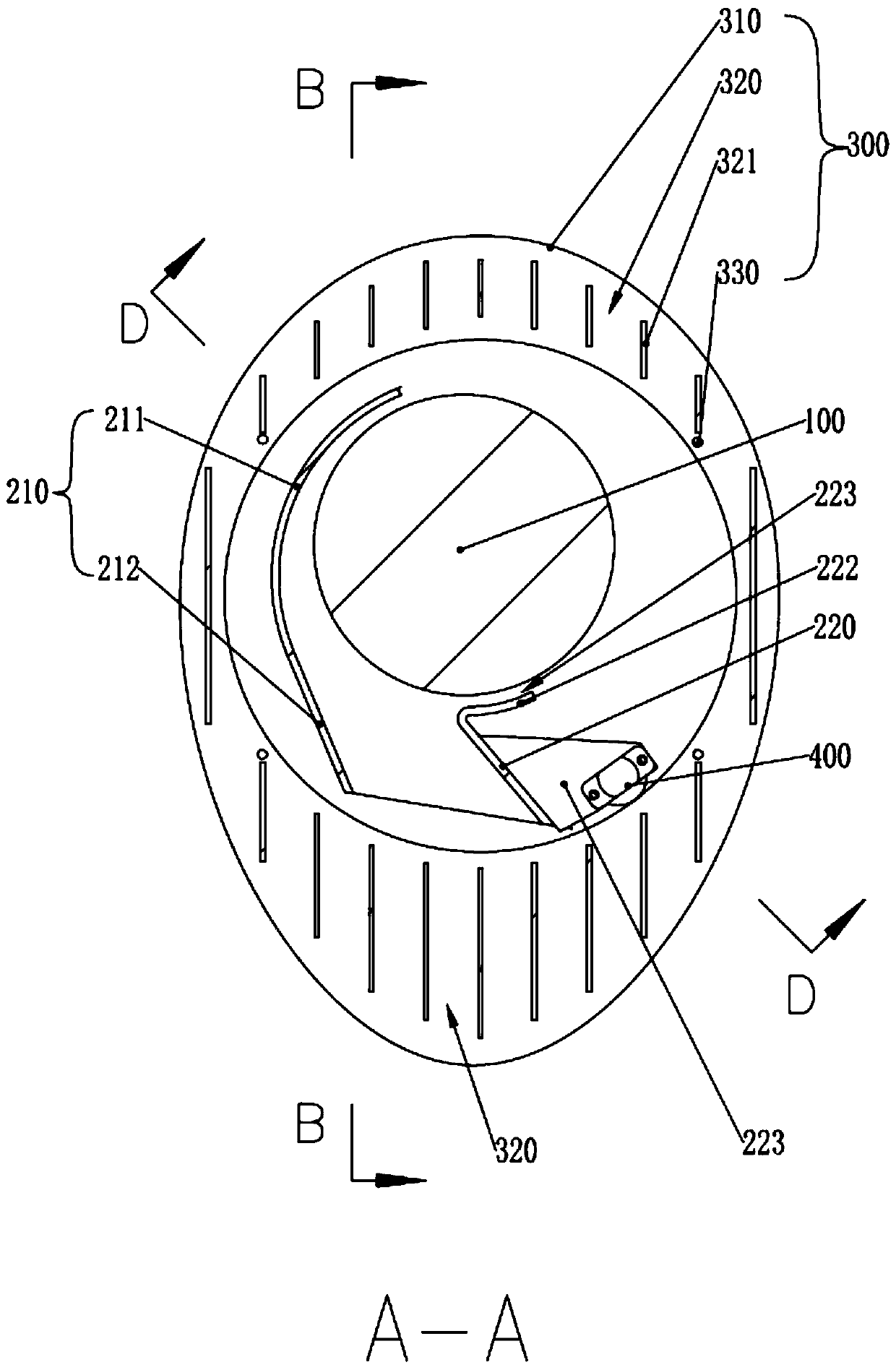

[0045] Embodiment 1: the driving gear 410 is a cylindrical gear, and the unit driving device 400 is installed on the air guide structure or the mounting bracket; the air channel layer structure is ring-shaped, and the inner ring is circular; the The driving gear 410 rotates in the horizontal plane; the ring rack is arranged along the inner ring of the air channel layer structure. In this solution, the drive mechanism is mainly distributed in the horizontal direction, which can make the installation structure of the air inlet and outlet array mechanism more precise in the vertical direction. The specific installation structure of the ring rack can also be: the inner ring of the air duct layer structure may not be set to be circular, and the ring rack can pass through a plurality of columns and the inner ring of the air duct layer structure The connection is fixed.

specific Embodiment approach 2

[0046] Embodiment 2: The driving gear 410 is a cylindrical gear, and the unit driving device 400 is installed on the wind guide structure or the mounting bracket; the driving gear 410 rotates in the horizontal plane; the ring rack is in the form of a ring shape, and is arranged on the upper surface or the lower surface of the air duct layer structure. In this solution, the driving mechanism is mainly distributed in the vertical direction, which can make the installation structure of the air inlet and outlet array mechanism more precise in the horizontal direction. In addition, the weight of the air duct layer structure can be driven by the unit As for the device, in the sub-plan, the interlayer support structures such as support columns can be simplified and not set up between the air duct layer structures.

[0047] During the use of the air outlet device, if the air duct layer structure can be driven horizontally, each layer of the air duct layer structure will not appear che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com