Linkage mechanism, air outlet array mechanism and air outlet equipment

A linkage mechanism and air outlet technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as the inability to change the air outlet and direction, adjustment of the use of blowing parameters, and limited use modes of air outlet equipment, etc., to achieve Diversified use states, good user experience, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

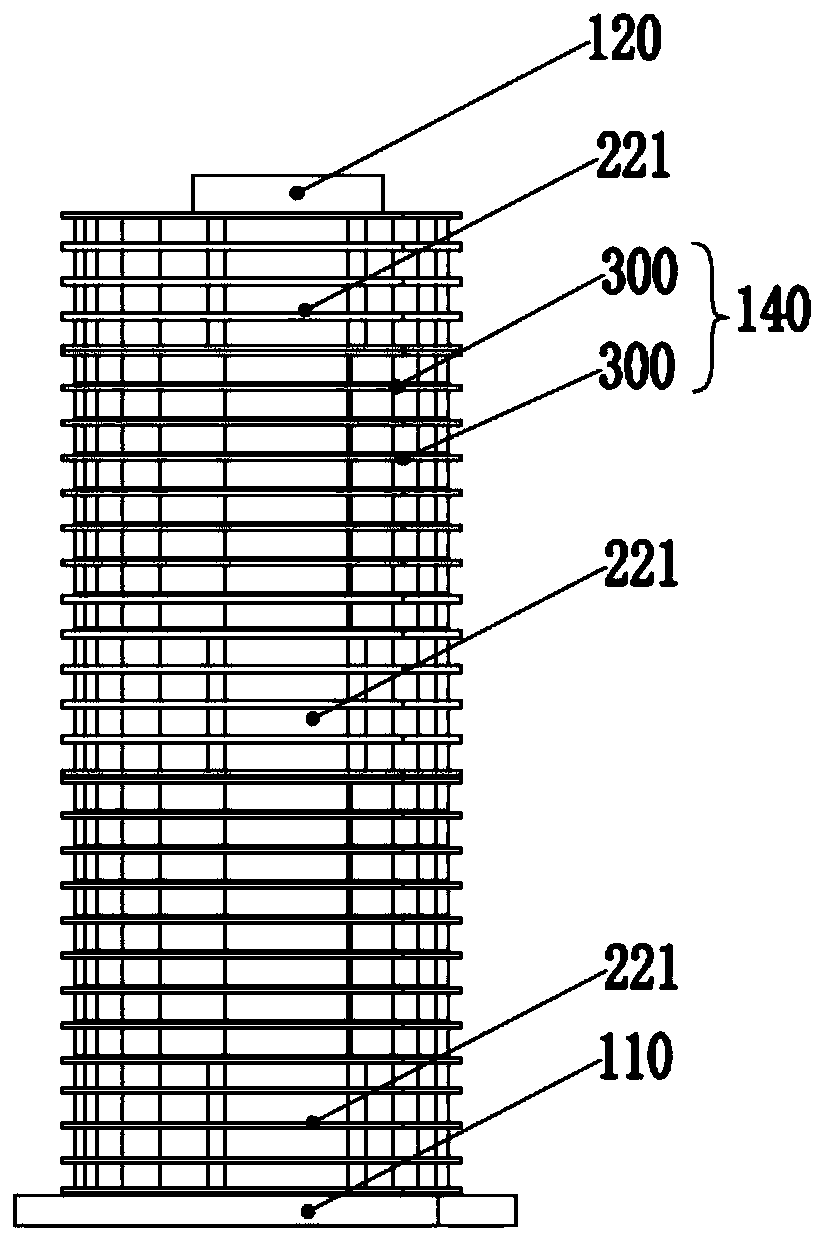

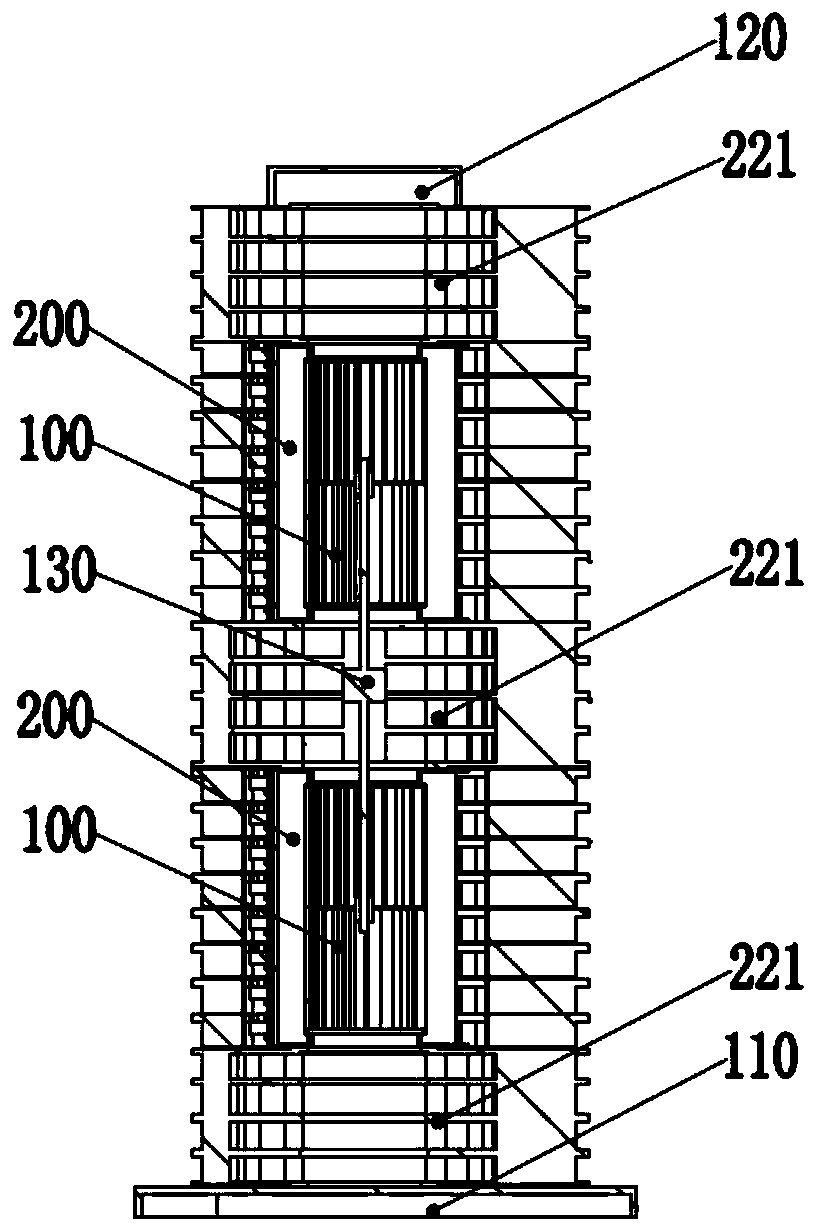

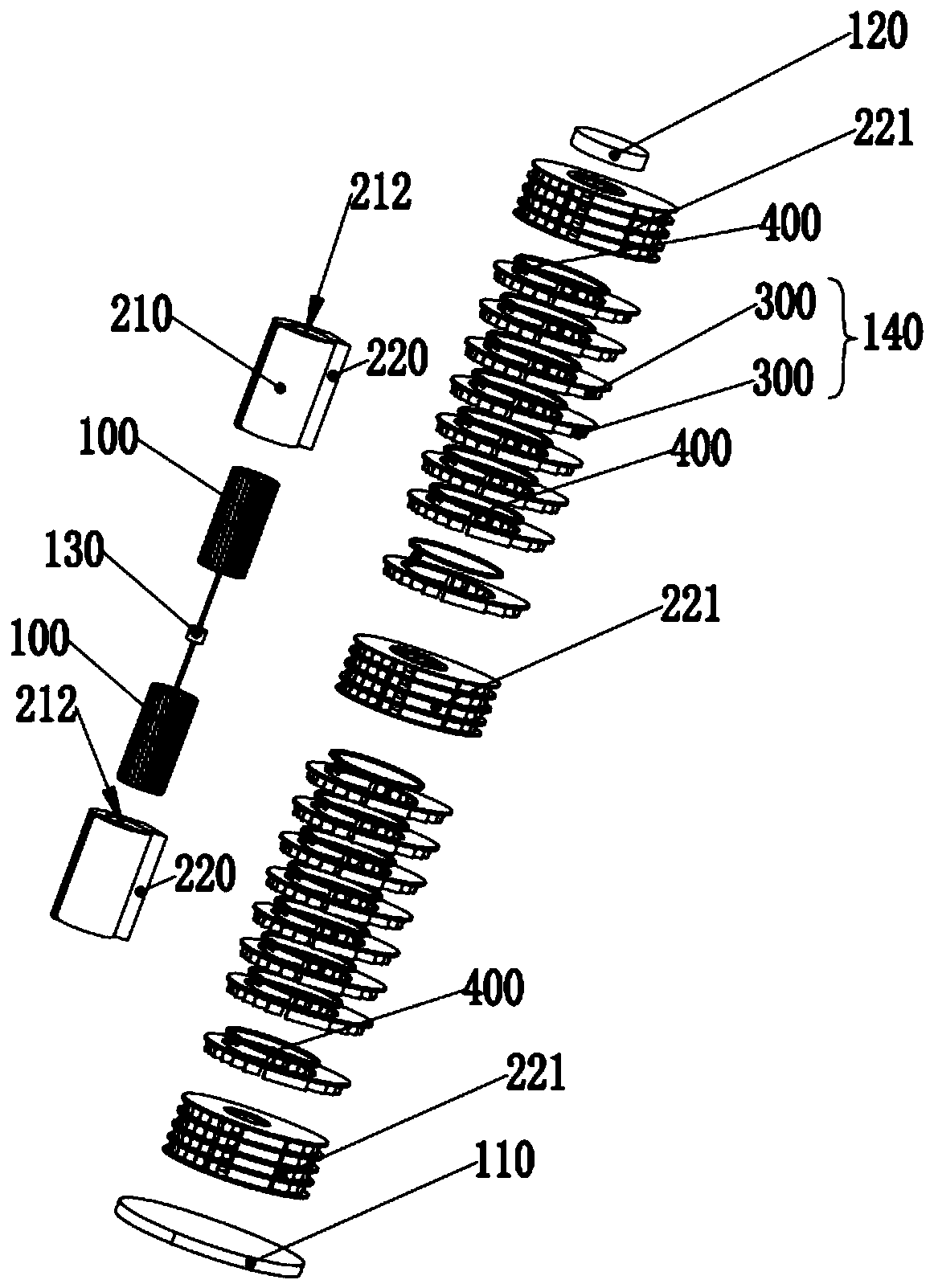

[0036] Such as Figure 1-7 As shown, an air outlet device includes: a centrifugal wind wheel 100, a wind wheel driving device 130, an air guide volute 210, and an air outlet array mechanism 140; the air outlet array mechanism 140 includes: The air channel layer structure; the air channel layer structure is a ring structure, and the middle part of the ring structure is provided with a hollowed out middle area; the centrifugal wind wheel 100 is vertically arranged in the wind guide volute 210, and is connected with the wind The wheel driving device 130 is connected by transmission; the side of the wind guide volute 210 is horizontally provided with an air outlet window 211, and the top and / or bottom of the wind guide volute 210 is provided with an air inlet 212; the air outlet array mechanism 140 The cover is arranged on the outside of the wind guiding volute 210 ; the air channel layer structure can rotate independently or combined horizontally around the wind guiding volute 21...

Embodiment 2

[0054] On the basis of Embodiment 1, an air outlet device is proposed, which also includes two sections of the air outlet array mechanism 140. Compared with Embodiment 1, the difference is that the two sections of the air outlet array mechanism in Embodiment 1 The driving mode and activity mode of 140 are the same, and a plurality of unit driving devices are used to respectively drive the rotation of the air duct layer structure of each layer; Embodiment On the basis of Embodiment 1, the air outlet array mechanism 140 described in the preceding paragraph is modified. Such as Figure 8 with 9 As shown, the specific implementation of the air outlet array mechanism 140 located in the upper section of the air outlet device is as follows:

[0055]The air outlet array mechanism 140 includes: a multi-layered air duct layer structure; the air duct layer structure is divided into an active layer and a linkage layer, and the active layer is located in the air outlet array mechanism 14...

Embodiment 3

[0061] On the basis of Embodiment 1, an air outlet device is proposed, which also includes two sections of the air outlet array mechanism 140. Compared with Embodiment 1, the difference is that the two sections of the air outlet array mechanism in Embodiment 1 The driving mode and activity mode of 140 are the same, and a plurality of unit driving devices are used to respectively drive the rotation of the air duct layer structure of each layer; the driving mode and activity mode of the air outlet array mechanism 140 described in the two sections in this embodiment are Differently, this embodiment modifies the air outlet array mechanism 140 described in the preceding paragraph on the basis of the first embodiment. Such as Figure 10-12 As shown, the specific implementation of the air outlet array mechanism 140 located in the upper section of the air outlet device is as follows:

[0062] The air outlet array mechanism 140 includes: a multi-layered air duct layer structure; the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com