A self-locking connecting mechanism

A connecting mechanism and self-locking technology, applied in the direction of railway vehicle coupling accessories, traction devices, railway car body parts, etc. Low and other problems, to achieve the effect of simple structure, high loading and unloading efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

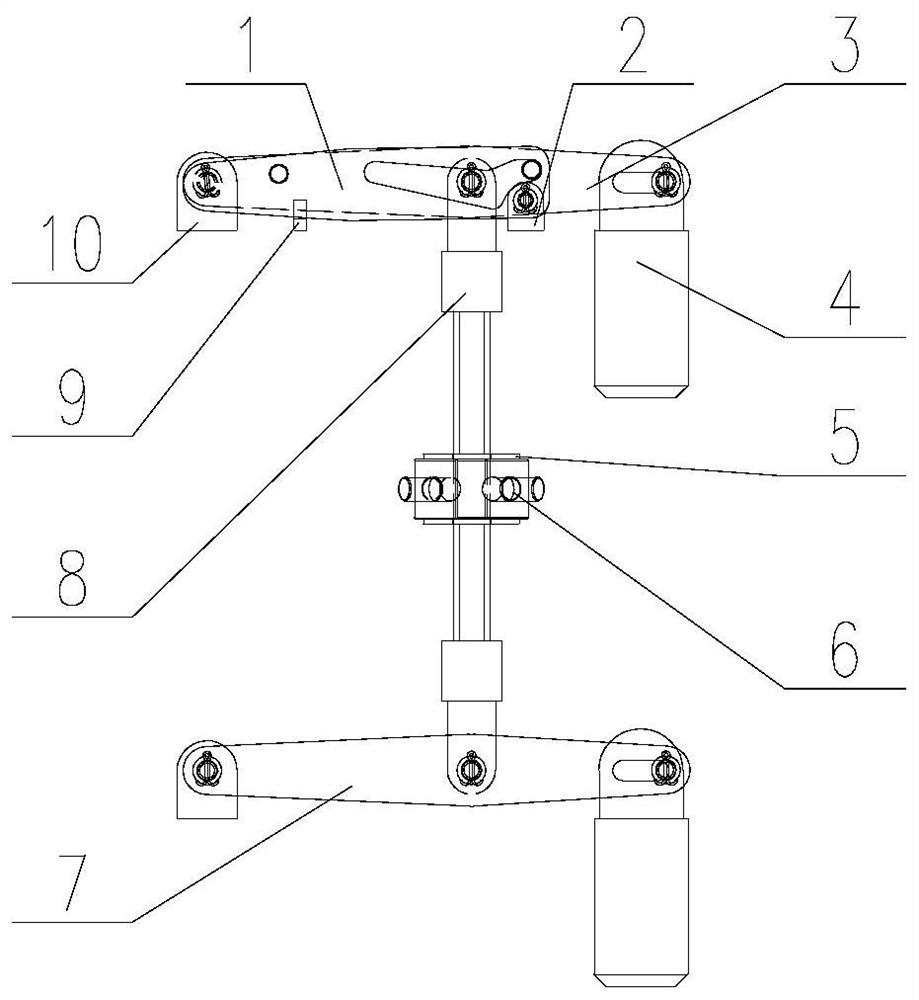

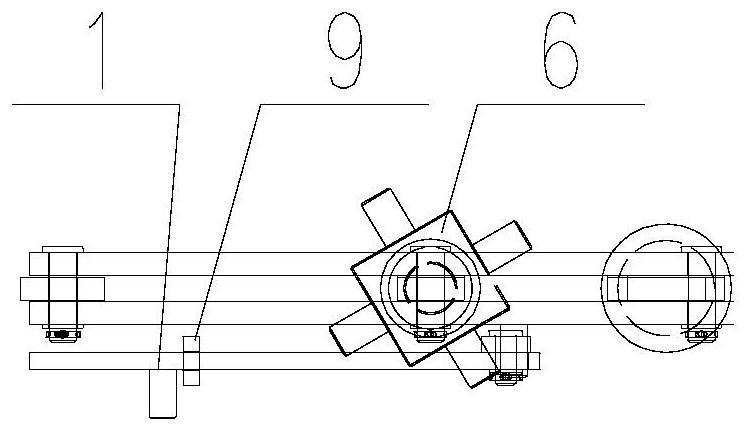

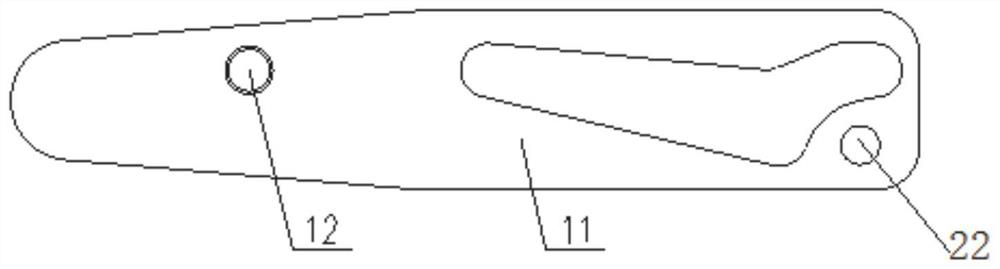

[0044] In a typical embodiment of the present invention, refer to figure 1 with figure 2 As shown, a connection mechanism that can realize self-locking includes a first element 1 and at least one second element, the second element has a first end that is movably connected with a first device such as a traction device 20, and the second element has a second The end is provided with a connecting piece that can be inserted into a second device such as a low-floor vehicle group, and the second end of the second element can be lifted, and one of the second elements has a protrusion, and the first element is arranged on the side of the second element, The first element 1 is provided with guide holes for accommodating the protrusions.

[0045] Among them, in order to realize the connection between the traction device and the low-floor vehicle group, the second element is arranged in two places up and down, and the upper and lower second elements are connected to the lifting parts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com