Stator of a rotating electrical machine

A technology for rotating electrical machines and stators, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., and can solve problems such as poor iron loss, unsuitable suppression of out-of-plane deformation of the iron core, and high magnetic flux density of the iron core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

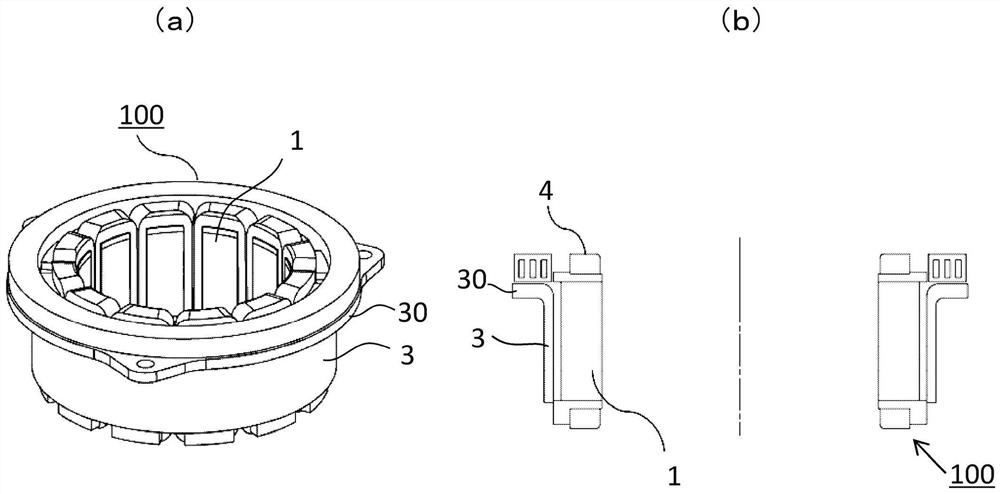

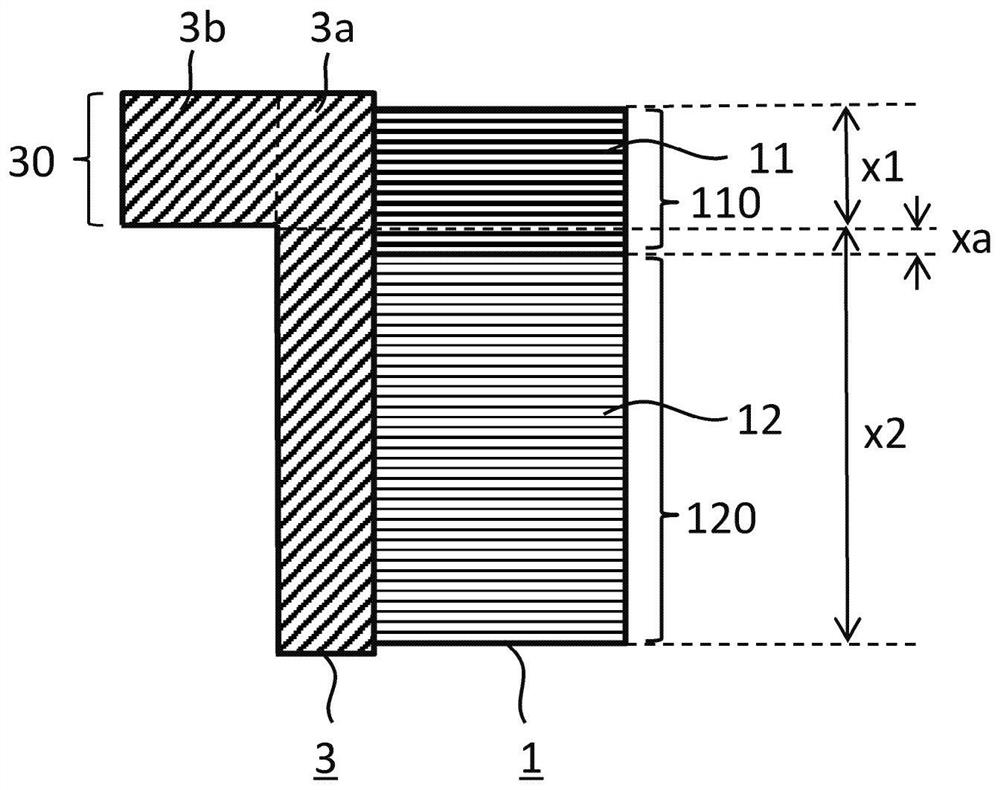

[0028] use Figure 1 to Figure 6 The stator 100 of the rotating electrical machine according to Embodiment 1 of the present application will be described. Additionally, use Figure 12 It is an explanatory diagram showing the state of the laminated iron core.

[0029] figure 1 (a) is a perspective view showing the stator 100 according to Embodiment 1, figure 1 (b) is along figure 1 Axial sectional view of the stator 100 of (a). As shown in these figures, the stator 100 is configured by inserting the laminated core 1 around which the coil 4 is wound, on the inner diameter side of the frame 3 extending in the axial direction in a cylindrical shape. In addition, the frame 3 has a frame high-rigidity portion 30 extending radially outward in a partial area in the axial direction, for example, an upper end side. The frame 3 may change its cross-sectional shape along the axial direction, and the cross-sectional area may change according to the change of the cross-sectional shape...

Embodiment approach 2

[0059] Next, refer to Figure 7 and Figure 8 Embodiment 2 of the present application will be described. In the above-mentioned example of Embodiment 1, the case where the frame 3 has the same shape in the circumferential direction has been described, but in this Embodiment 2, the following case will be described: Figure 7 As shown in the cross-sectional view of the main part of the stator 100, the frame cylindrical portion 3a is not simply cylindrical. The notch 31 penetrating the frame cylindrical portion 3 a is arranged in a notch forming region 31 a which is an intermediate position in the axial direction of the frame 3 .

[0060] Figure 8 (a), (b), (c) are along with Figure 7 The cross-sectional views of the frame 3 on the B1-B1 line, B2-B2 line, and B3-B3 line, which are perpendicular to the axial direction, respectively represent the area where the frame extension 3b is provided, the slot forming area 31a where the slot 31 is provided, The cross-sectional struct...

Embodiment approach 3

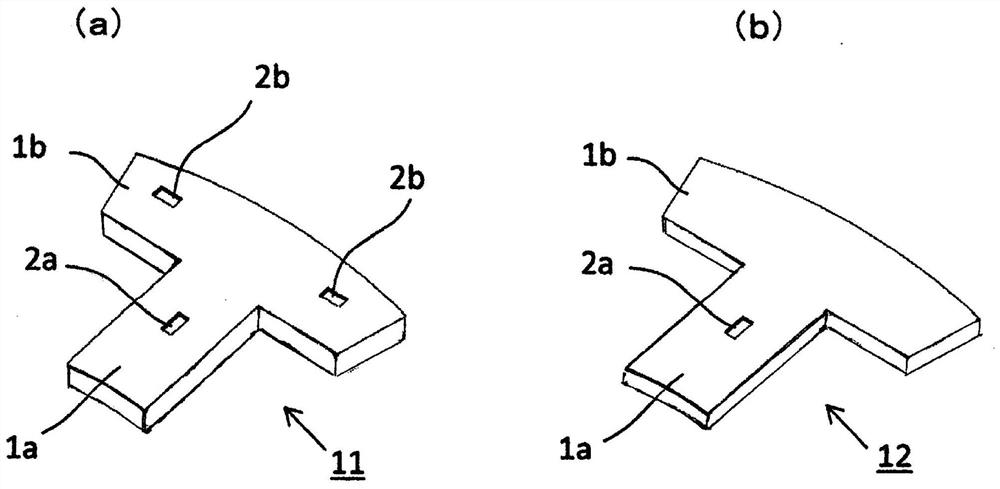

[0068] Next, Embodiment 3 of the present application will be described. In this embodiment 3, use Figure 9 and Figure 10 Modifications of the first core 11 and the second core 12 will be described.

[0069] As described above, the first iron core 11 and the second iron core 12 are divided into the pole tooth portion 1a on which the wire is wound and the iron core back 1b forming a ring in the circumferential direction, and the riveting 2a and the riveting 2b are all provided. On the core back 1b.

[0070] Figure 9 (a) is a top view of the first iron core 11 as an example, and shows the riveting 2a provided on the entire length of the laminated iron core 1 in the axial direction and the riveting 2b additionally provided to strengthen the fastening force between the cores. In the state where one layer of first iron cores 11 is provided, at the center of the core back 1b in the circumferential direction, a riveting member 2a is provided on the inner side in the radial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com