Anti-shock fire-fighting lance

A water gun and firefighting technology, applied in fire rescue and other directions, can solve the problems of property loss, high water pressure, labor and other problems, and achieve the effect of increasing the coverage area of water flow and improving the efficiency of fire extinguishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

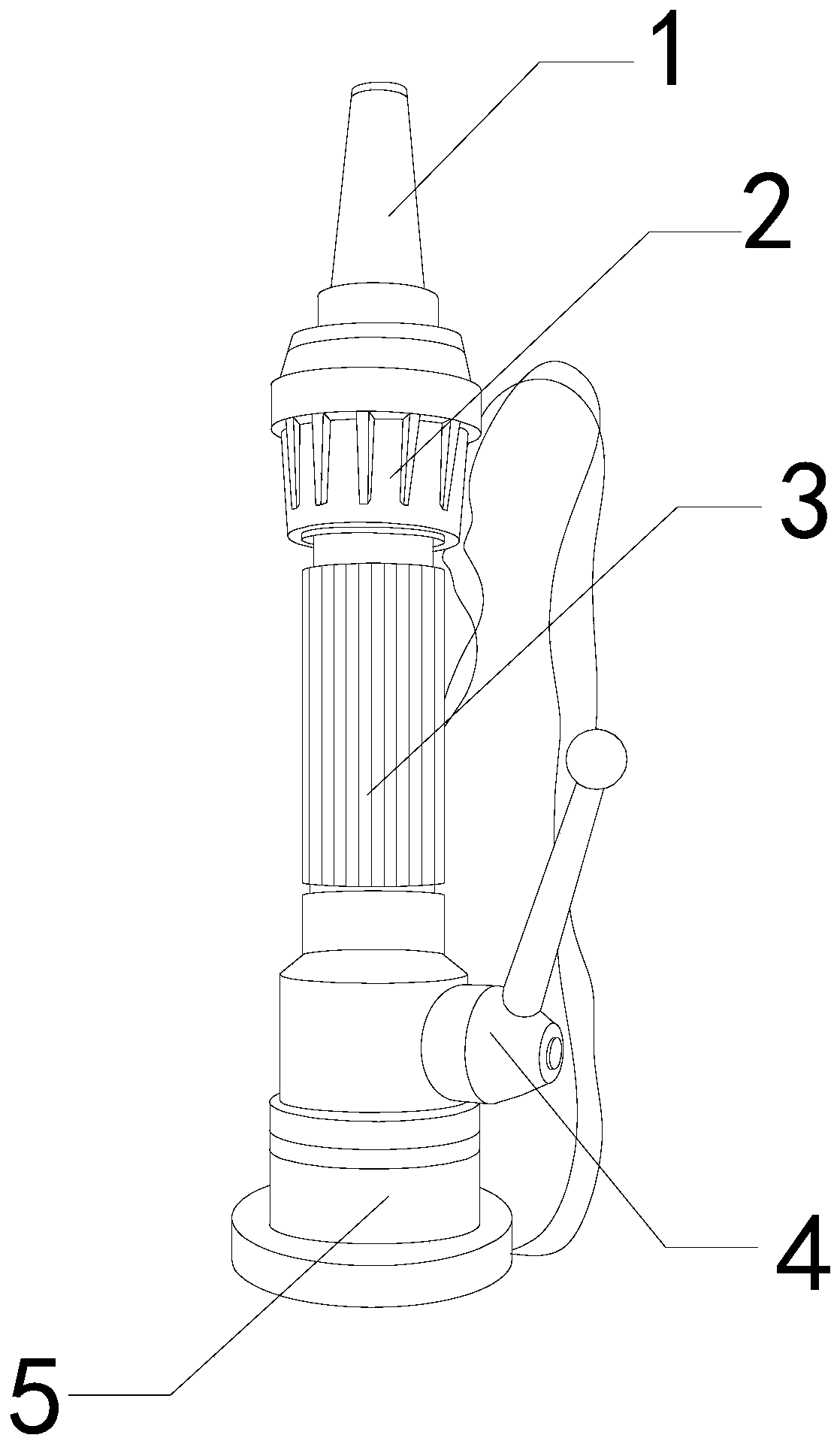

[0025] For example figure 1 -example Figure 4 Shown:

[0026] The invention provides a shock-absorbing fire-fighting water gun, the structure of which includes a spray head 1, a compression end 2, a conduit 3, a valve 4, and a connecting end 5. The conduit 3 is embedded in the lower end of the compression end 2, and the valve 4 It is movably engaged with the conduit 3 , the connecting end 5 is welded to the conduit 3 , and the spray head 1 is installed at the upper end of the compression end 2 .

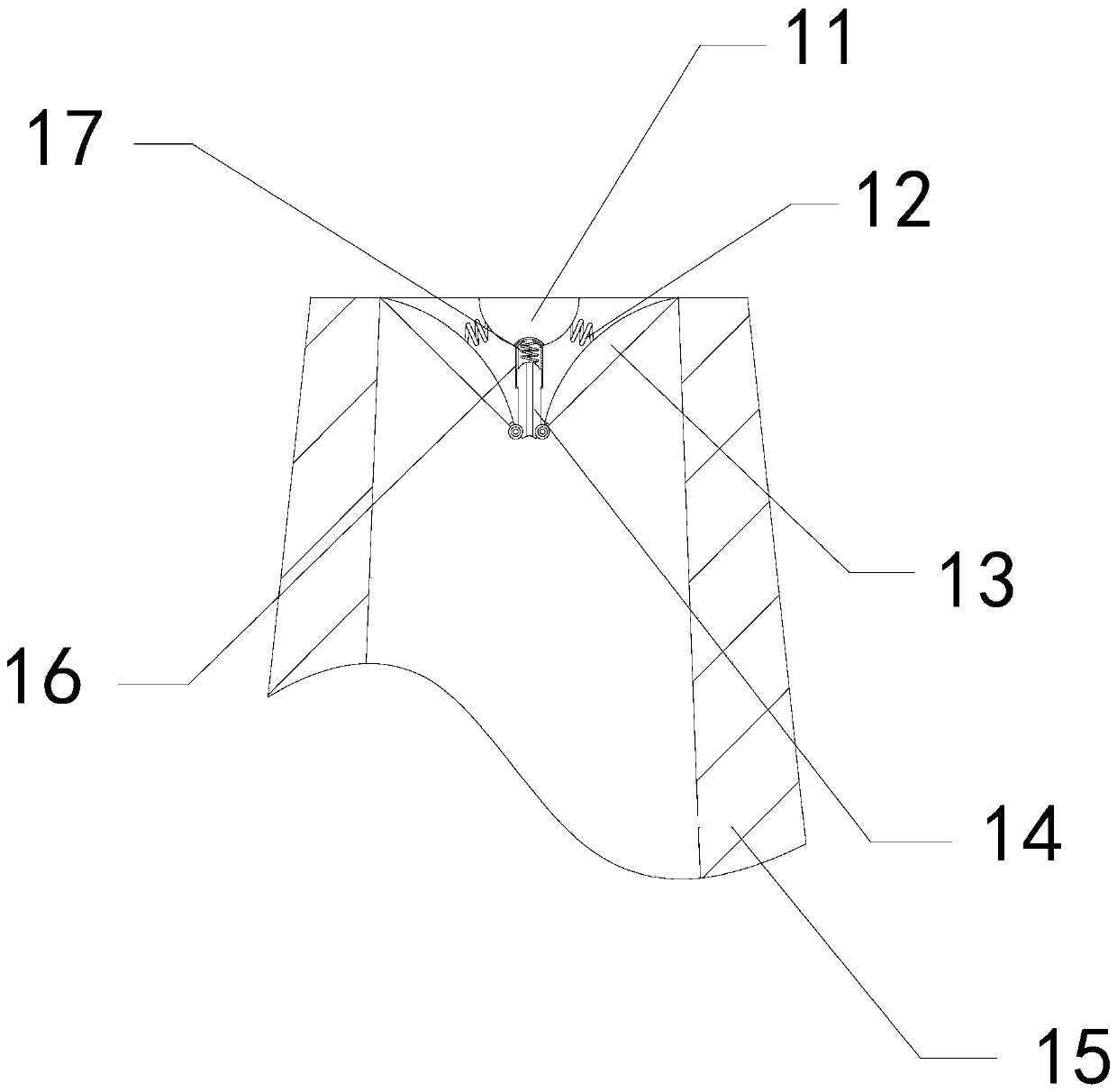

[0027] Wherein, the spray head 1 includes a resisting block 11, an elastic bar 12, a diffuser plate 13, a force bar 14, a frame body 15, a casing 16, and an elastic bar 17, and the resisting block 11 and the frame body 15 are an integrated structure. , the elastic bar 12 is installed between the resisting block 11 and the diffuser plate 13, the diffuser plate 13 is hingedly connected with the force bar 14, the force bar 14 is clearance-fitted with the casing 16, and the inside of ...

Embodiment 2

[0033] For example Figure 5 -example Figure 7 Shown:

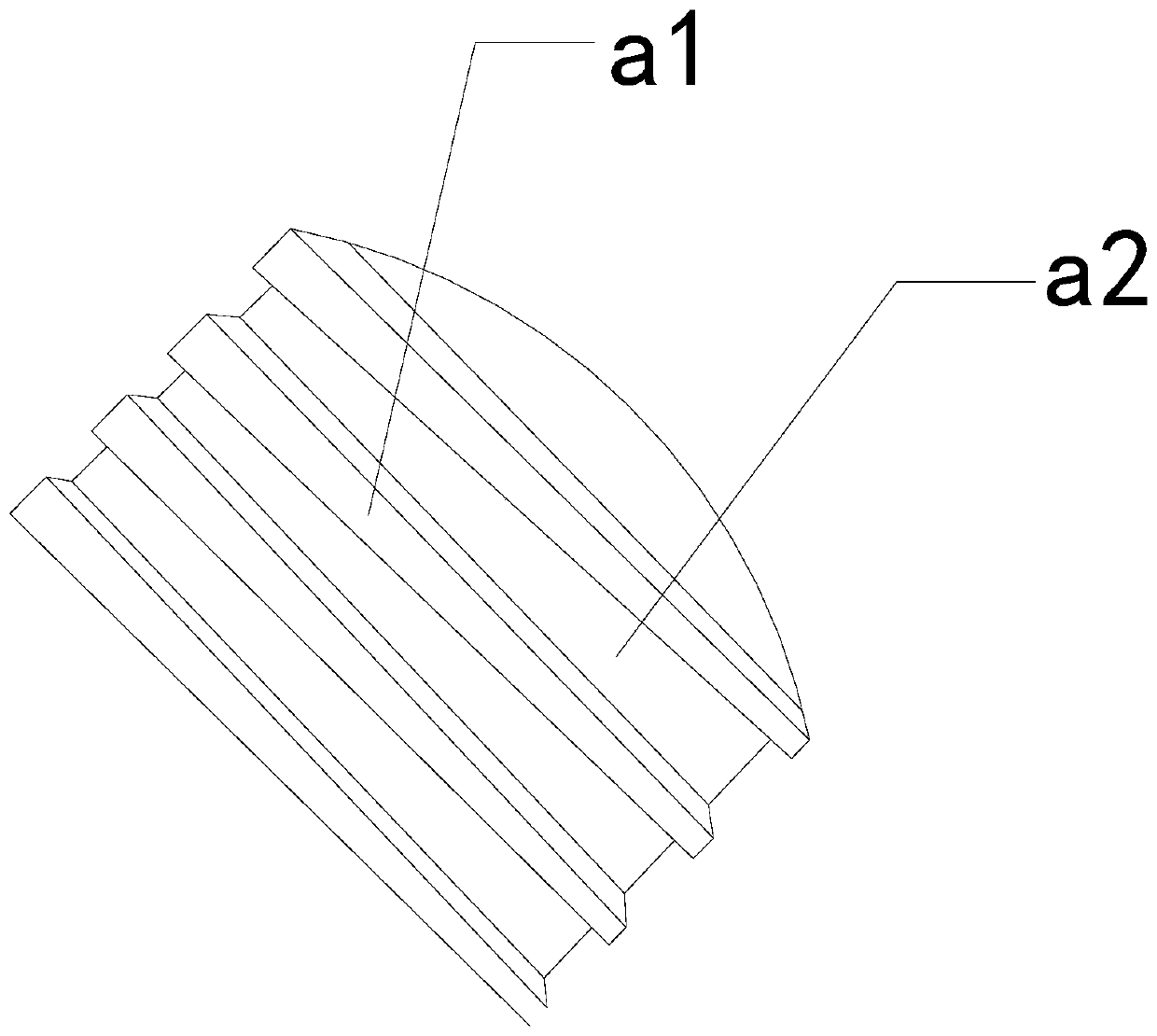

[0034] Wherein, the resisting block 11 includes a block body b1, a water guiding cavity b2, and a spraying mechanism b3. The water guiding cavity b2 and the block b1 are an integrated structure, and the spraying mechanism b3 is installed on the side of the water guiding cavity b2. At the upper end of the inner wall, the water guide chamber b2 is narrow at the top and wide at the bottom, which can enhance the water pressure of the water jet.

[0035] Wherein, the ejection mechanism b3 includes a top block b31, a water permeable hole b32, and a buffer mechanism b33. The water permeable hole b32 runs through the inner position of the top block b31, and the buffer mechanism b33 is installed at the bottom of the top block b31. The permeable hole b32 can disperse the water jetted from b13, avoiding the direct jetting flow of the water is too large, so that the quality is too large, resulting in the water falling too fast and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com