Neural network-based lifting load measurement method for automobile crane

A neural network-based technology for truck cranes, applied in the field of truck crane hoisting load measurement, can solve problems such as inaccurate measurement results, time-consuming and labor-intensive measurement, susceptibility to dynamic changes in arm moment, multiple mechanical friction, and wire rope sagging, etc., to achieve The effect of reducing environmental disturbance and system error, low cost, and convenient stability evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiments and drawings.

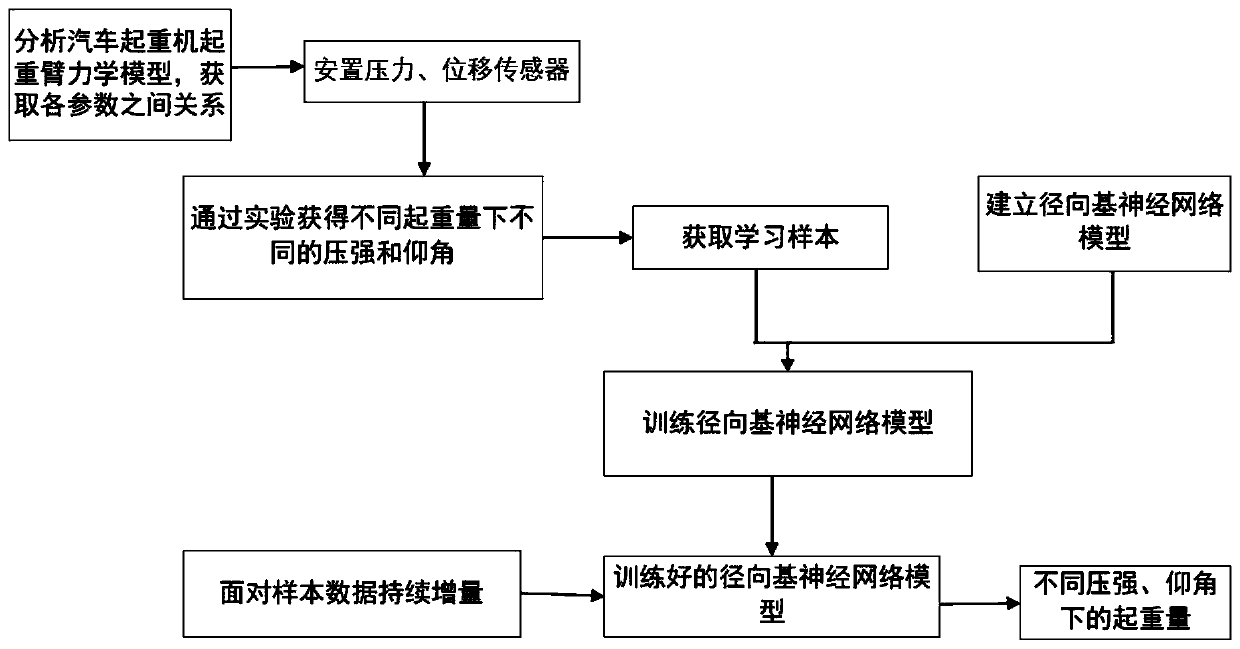

[0032] Such as figure 1 As shown, the method for measuring the lifting load of a truck crane based on a neural network in this embodiment includes the following steps:

[0033] (1) Analyze the mechanical model of the truck crane boom

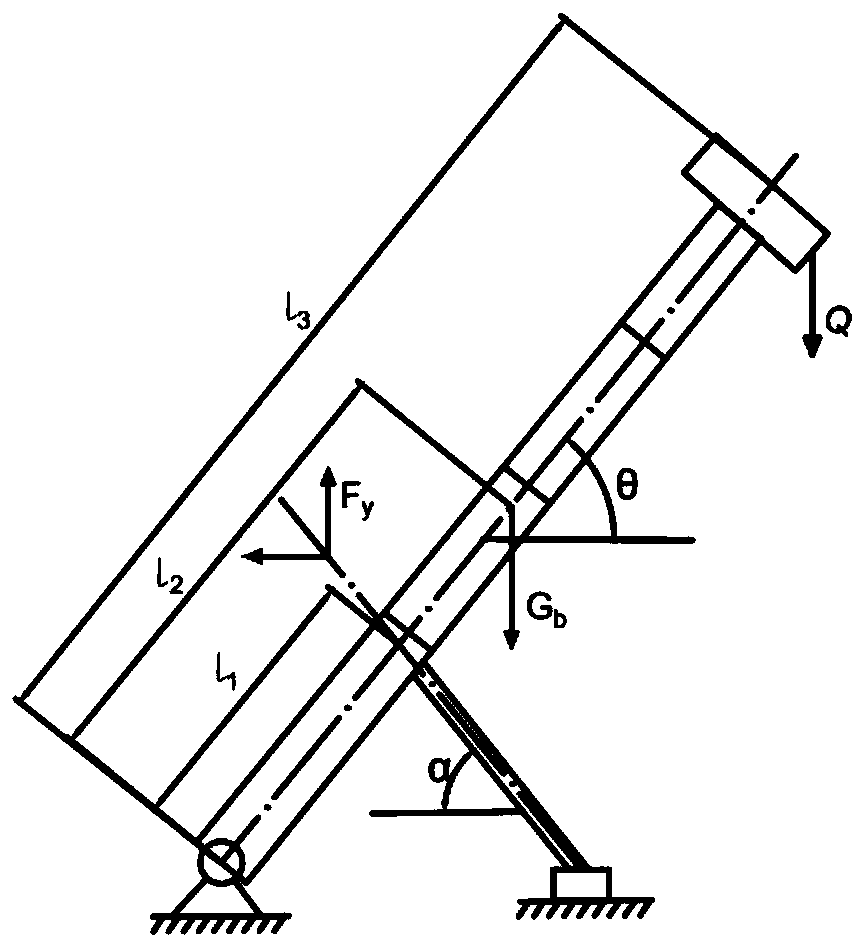

[0034] Through the structural characteristics and geometric parameters of the truck crane boom, the mechanical model of the boom under load is established, such as figure 2 As shown in the figure, Q is the lifting load of the truck crane, G b Is the mass of the boom, θ is the elevation angle of the boom, α is the elevation angle of the luffing cylinder, l 1 Is the distance from the starting point of the boom to the contact point of the luffing cylinder, l 2 Is the distance from the starting point of the boom to the center of gravity of the boom, l 3 It is the total length of the boom when it is working, and Fy is the vertical support force of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com