Marine hose fluid leakage detection system

A fluid leakage and sensing system technology, applied in the field of fluid leakage sensing systems for marine hoses, can solve problems such as difficulty in sensing fluid leakage, structural changes in marine hoses, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a fluid leakage sensing system for a marine hose (hereinafter referred to as a sensing system) according to the present invention will be described based on the embodiment shown in the drawings.

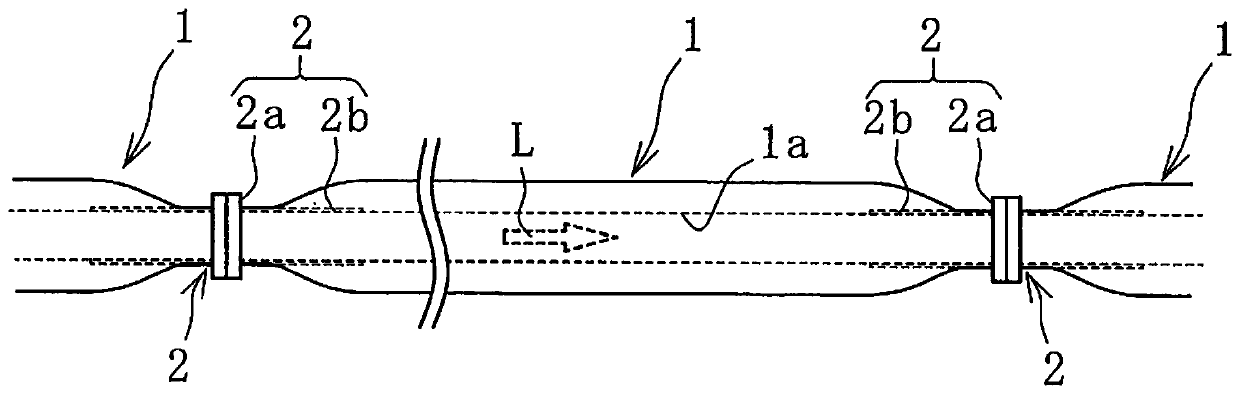

[0022] Such as figure 1 As shown, the marine hose 1 has connection end portions 2 for connecting to other marine hoses 1 at both ends in the longitudinal direction thereof. The connecting end portion 2 has a pipe joint 2b extending in the longitudinal direction of the marine hose 1 , and a flange 2a joined to one end of the pipe joint 2b in the longitudinal direction. Generally, about eight or more and ten or less hoses 1 for ships are connected and used.

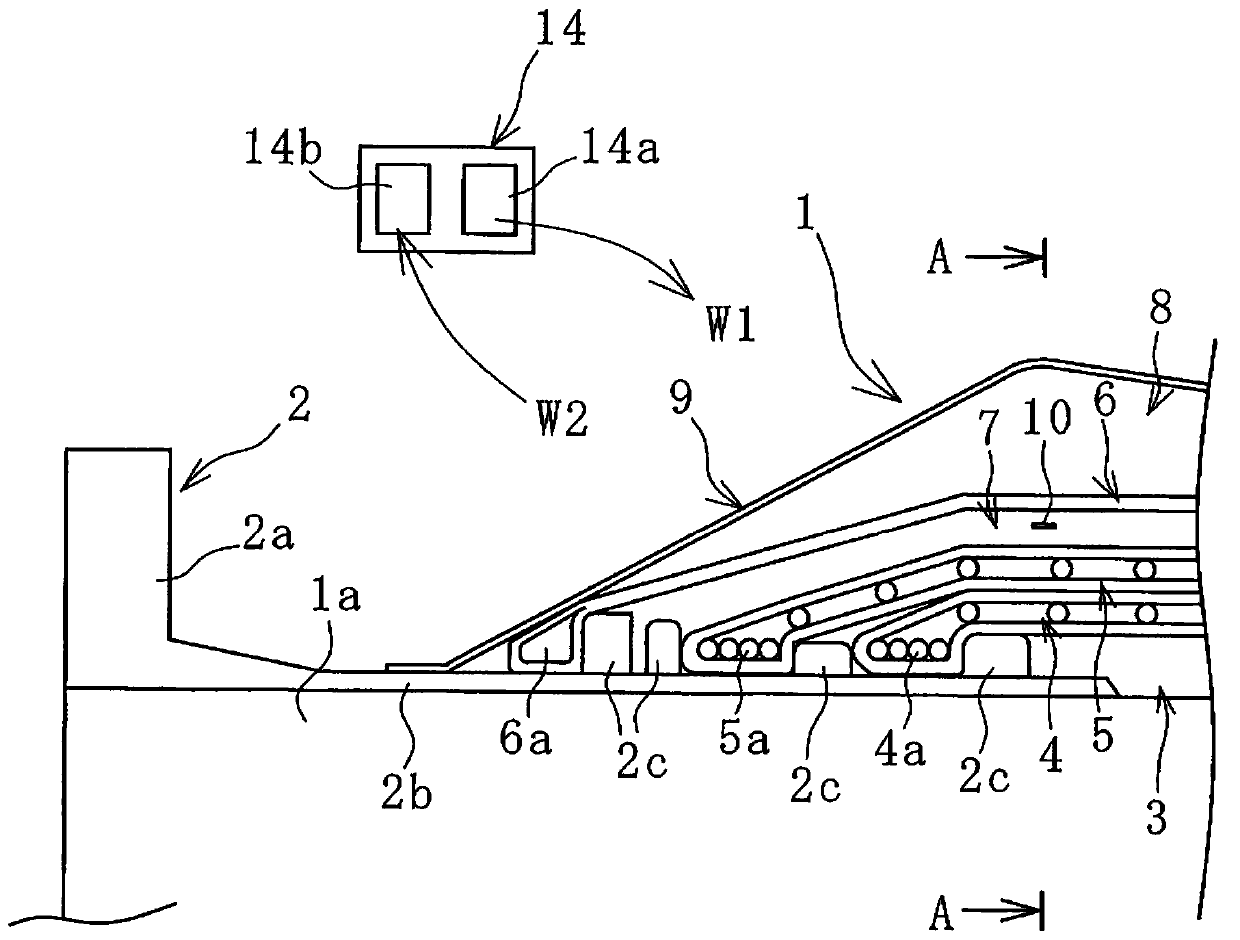

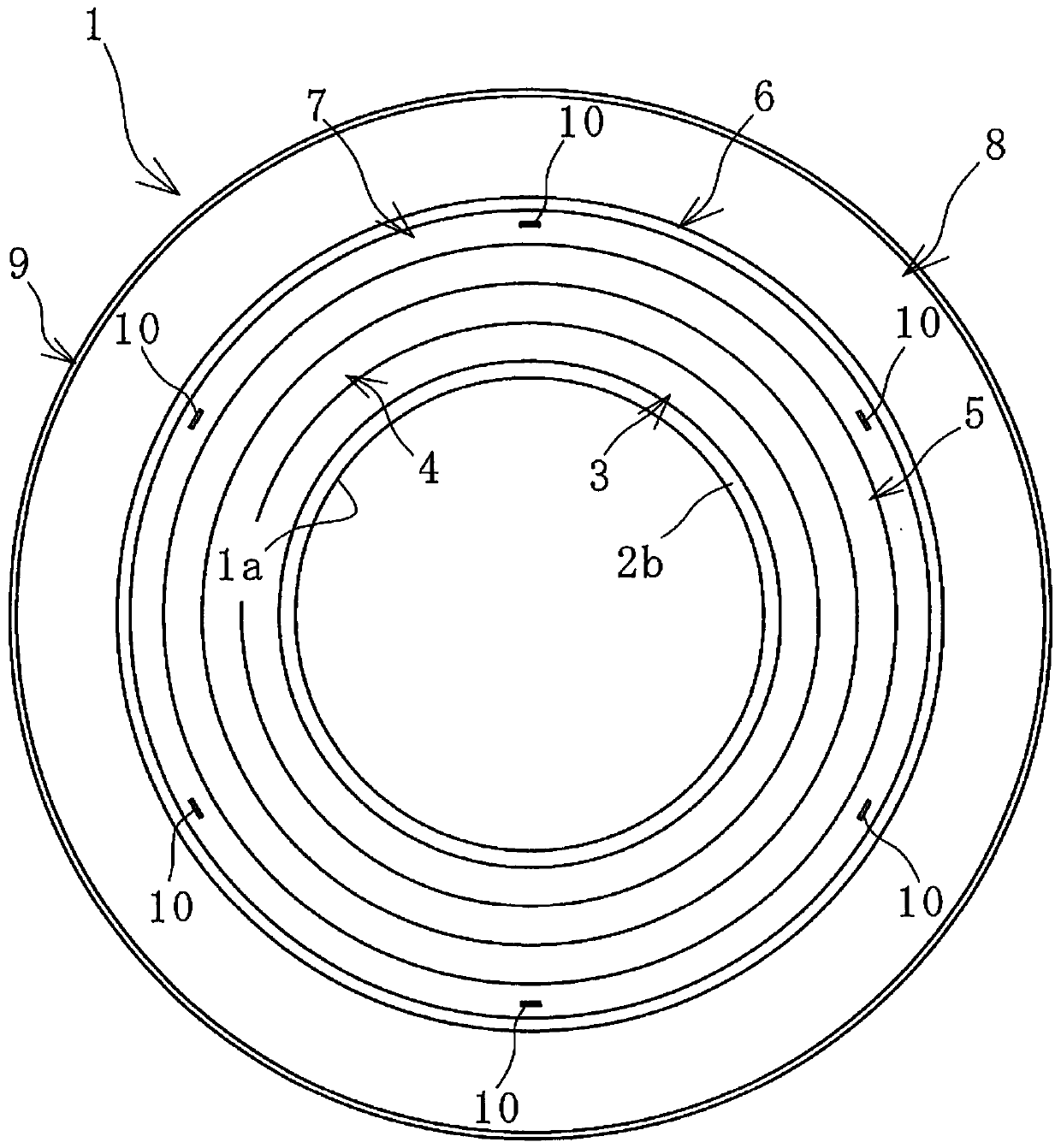

[0023] Between the pipe joints 2b at both ends of the marine hose 1, such as figure 2 As an example, on the outer peripheral side of the flow path 1a, an inner surface rubber layer 3, an inner peripheral side reinforcing layer 4, a main body thread layer 5, and a fluid retaining layer are laminated in this o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com