A gas diversion control device for a combustion chamber

A diversion control, combustion chamber technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of polluted gas, waste of resources, high flame front temperature, etc., achieve low combustion emissions and ensure air supply pressure , the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

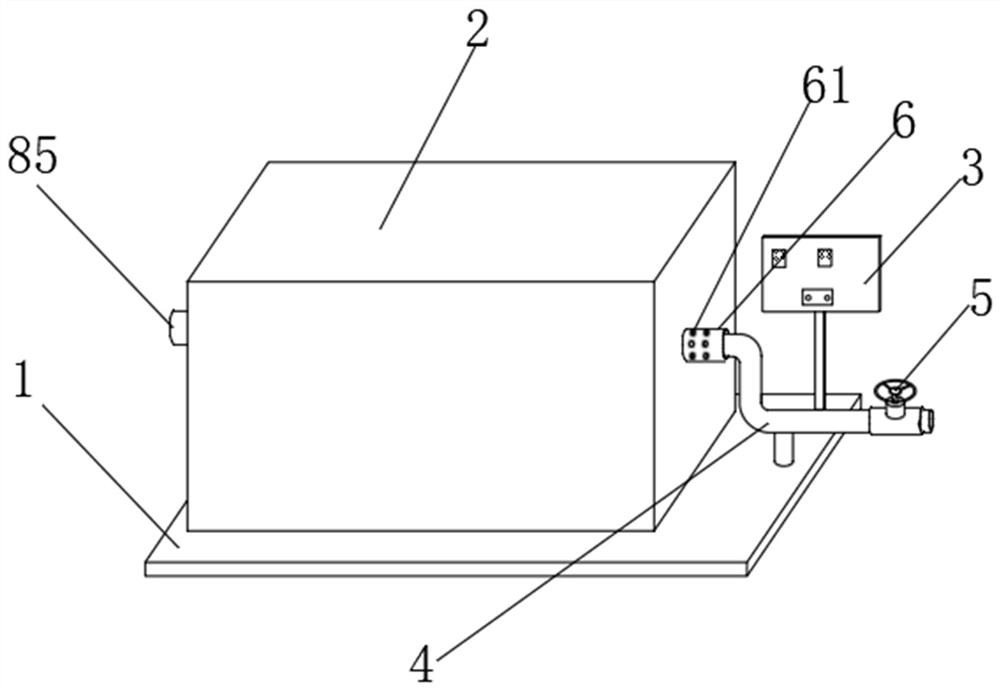

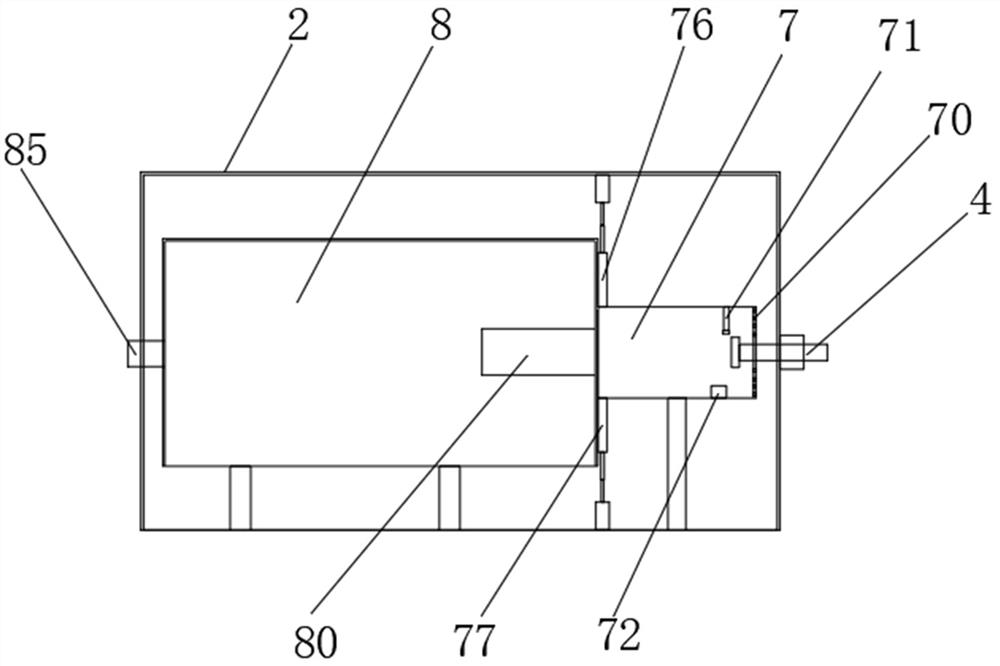

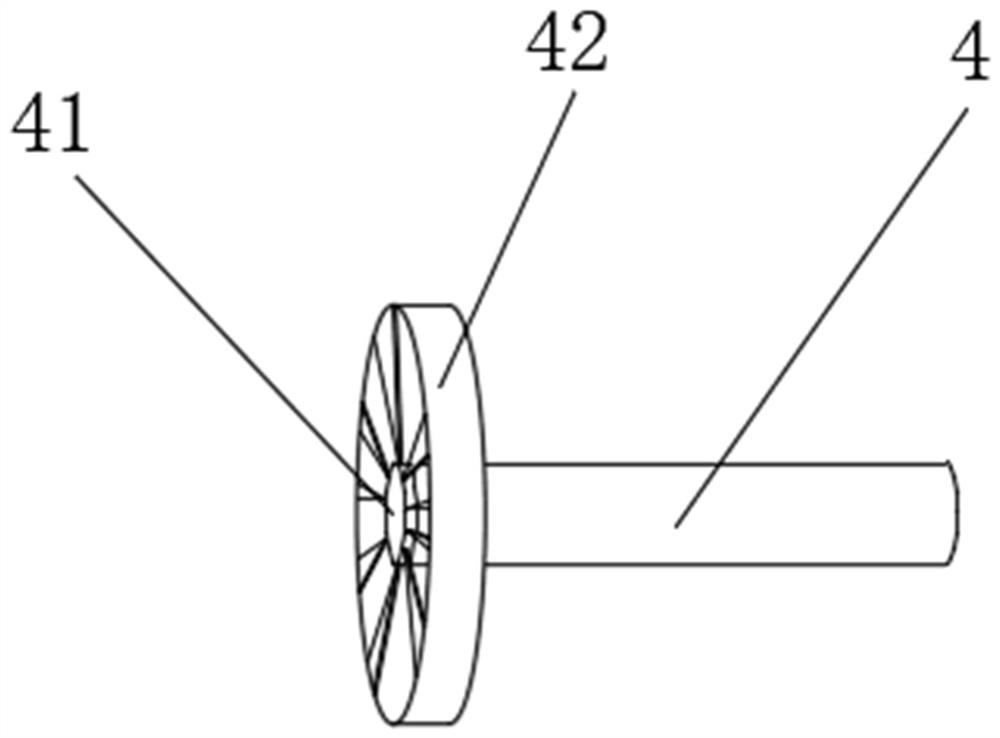

[0030] like Figure 1-7 As shown, a gas flow control device of a combustion chamber includes a base (1), the outer casing (2), and the control panel (3), the outer casing (2) is fixed to the upper end surface of the base (1), the control panel ( 3) Located in the upper end surface of the base (1), and the control panel (3) is located on one side of the outer casing (2), and a mount (6) is provided on one side of the outer casing (2), and the mounting tube (6) The inside is hollow, and the outer circumference of the mounting tube (6) is provided with auxiliary intake hole (61) such as a symmetric symmetric setting, and the base (1) is also provided with a gas pipe (4), gas pipe (4). One end is inserted inside the mounting cylinder (6), and the external air enters the interior of the outer casing (2) from the inside of the mounting tube (6), and the inside of the outer casing (2), one end of the gas pipe (4) runs through the installation The cartridge (6) and extends to the interior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com