Composition for nasal cavity

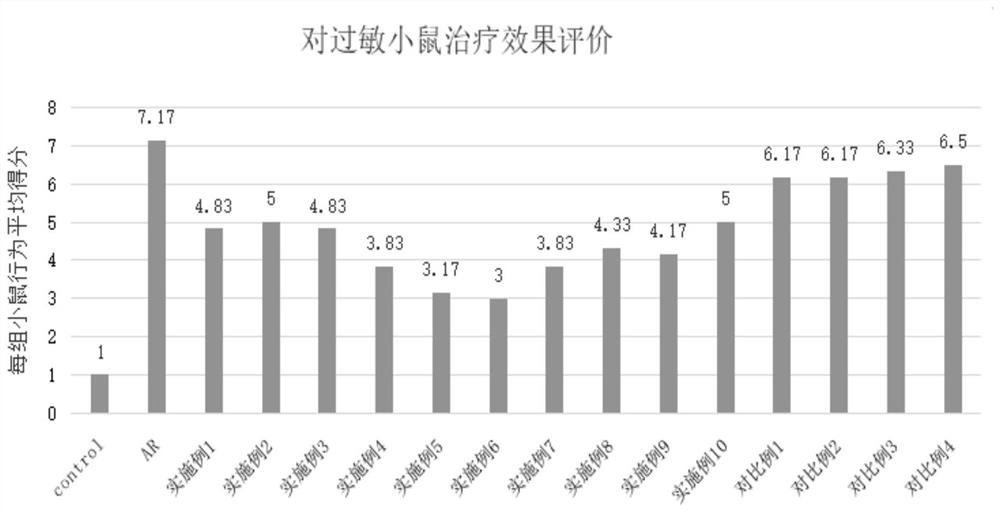

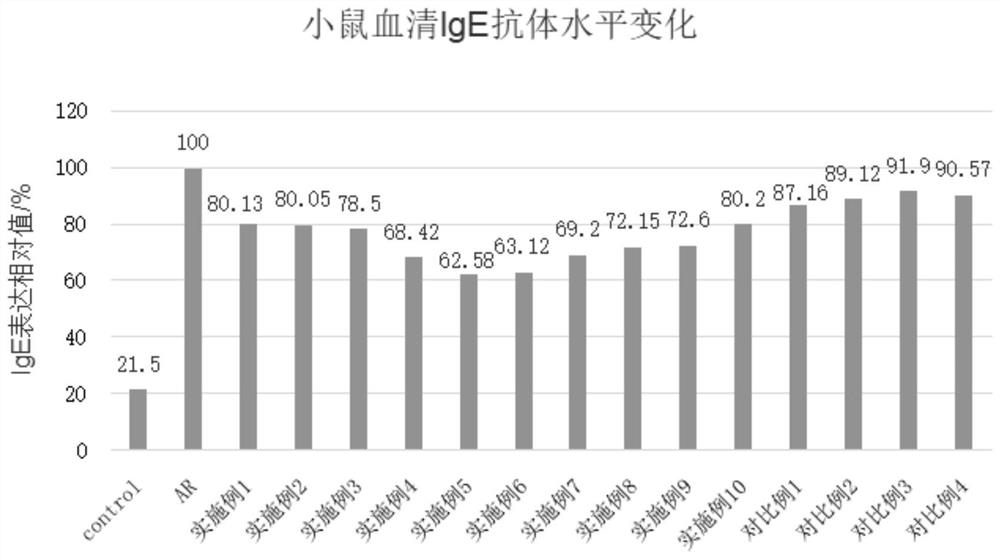

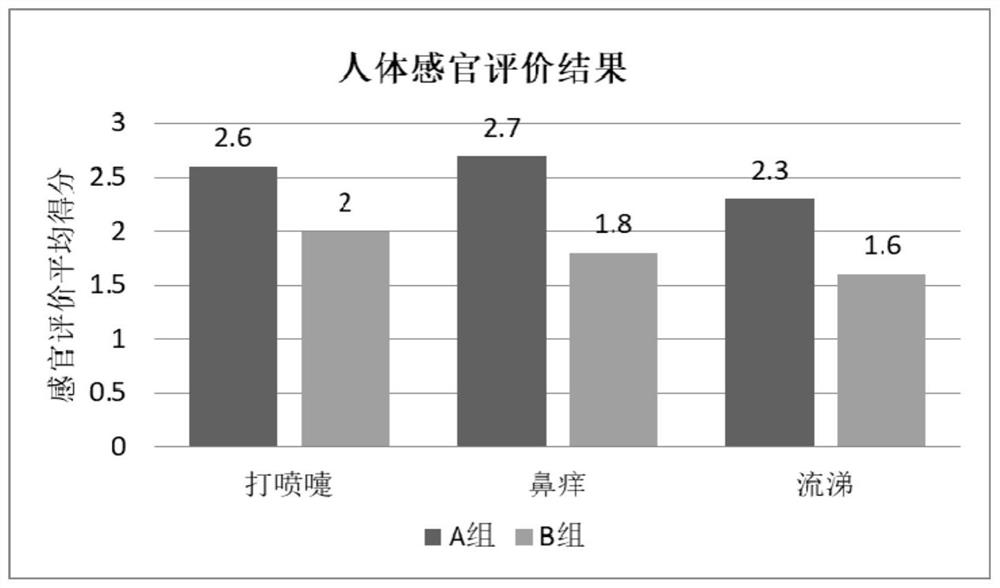

A composition and a nasal technology, which are applied in the prevention or treatment of nasal dryness and allergies, can solve problems such as unsatisfactory curative effect and short action time, and achieve the effect of increasing external stimulation threshold and reducing the probability of nasal diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Under stirring, add 0.2g of hyaluronic acid tetrabutylammonium salt (molecular weight: 3 million Daltons) into 80g of purified water at 80-95°C, stir to dissolve completely, and then add 0.1g of tetrahydromethylpyrimidinecarboxylic acid Add, stir at 80-95°C until dissolved, then slowly stir and keep warm for 25 minutes, then slowly cool down to 30-40°C, then add 3.8g hyaluronic acid tetrabutylammonium salt (molecular weight: 0.1 thousand Daltons) , stir to make it completely dissolve, and obtain phase A material; at the same time, add 0.15g of PPG-26 butane-26 / PEG-40 hydrogenated castor oil, 0.7g of phenoxyethanol, 0.1g of ethylhexylglycerin and 0.015g of peppermint essential oil Add up to 10g of purified water to obtain the material of phase B; then add the material of phase B to the material of phase A, and wash the container containing the material of phase B with a small amount of purified water, pour the cleaning solution into phase A together, and then add purified...

Embodiment 2

[0092] Under stirring, add 0.15g of tetrabutylammonium hyaluronic acid (molecular weight: 1.2 million Daltons) into 80g of purified water at 80-95°C, stir to dissolve completely, and then add 6g of tetrahydromethylpyrimidinecarboxylic acid into , stir at 80-95°C until dissolved, then slowly stir and keep warm for 25 minutes, then slowly cool down to 30-40°C, then add 0.15g hyaluronic acid tetrabutylammonium salt (molecular weight: 50,000 Daltons), Stir to dissolve completely to obtain phase A material; at the same time, add 0.15g of PPG-26 butane-26 / PEG-40 hydrogenated castor oil, 0.7g of phenoxyethanol, 0.1g of ethylhexylglycerin and 0.015g of peppermint essential oil to 10g Purified water to obtain phase B material; then add phase B material to phase A material, and clean the container containing phase B material with a small amount of purified water, pour the cleaning liquid into phase A together, and then add purified water to 100g of the material liquid, Stir to make it e...

Embodiment 3

[0094] Under stirring, add 0.5g of hyaluronic acid tetrabutylammonium salt (molecular weight: 1.8 million Daltons) into 80g of purified water at 80-95°C, stir to dissolve it completely, and then add 0.5g of tetrahydromethylpyrimidinecarboxylic acid Add, stir at 80-95°C until dissolved, then slowly stir and keep warm for 25 minutes, then slowly cool down to 30-40°C, then add 1.0g hyaluronic acid tetrabutylammonium salt (molecular weight: 10,000 Daltons) , stir to make it completely dissolve, and obtain phase A material; at the same time, add 0.15g of PPG-26 butane-26 / PEG-40 hydrogenated castor oil, 0.7g of phenoxyethanol, 0.1g of ethylhexylglycerin and 0.015g of peppermint essential oil Add up to 10g of purified water to obtain the material of phase B; then add the material of phase B to the material of phase A, and wash the container containing the material of phase B with a small amount of purified water, pour the cleaning solution into phase A together, and then add purified ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap