A trip protection device for wire rope take-up

A tripping protection, wire rope technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of wire rope skipping, wire breakage, affecting the production quality and production efficiency of wire rope, and avoid wire breakage , Guarantee the effect of production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are given in conjunction with the embodiments.

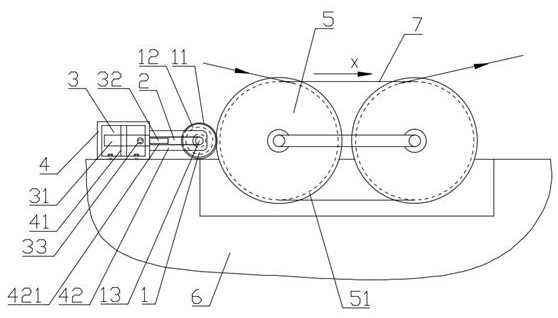

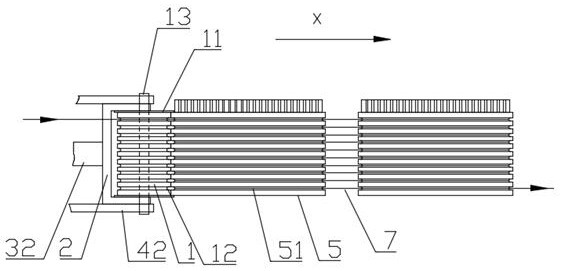

[0019] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the overall structure of a trip protection device for wire rope take-up of the present invention, figure 2 It is a top view of the top pulley of a tripping protection device for wire rope take-up of the present invention when the top pulley is in working state.

[0020] like figure 1 and figure 2 As shown, the present invention provides a tripping protection device for wire rope take-up, comprising a top pulley 1, a fixed frame 2, an adjustment structure 3 and a fixed seat 4, the top pulley 1 is rotatably embedded in the fixed frame 2, and the fixed frame 2 It is fixedly connected with the adjustment structure 3, usually by welding, to ensure the stability of the structural conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com