Fair-faced concrete for bridge structures under marine environment and preparation method thereof

A technology of fair-faced concrete and bridge structures, applied in the field of building materials, can solve the problems of insufficient durability of fair-faced concrete and the inability to apply bridge structures, etc., achieve the effects of abundant reserves, local materials, and enhanced slump performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

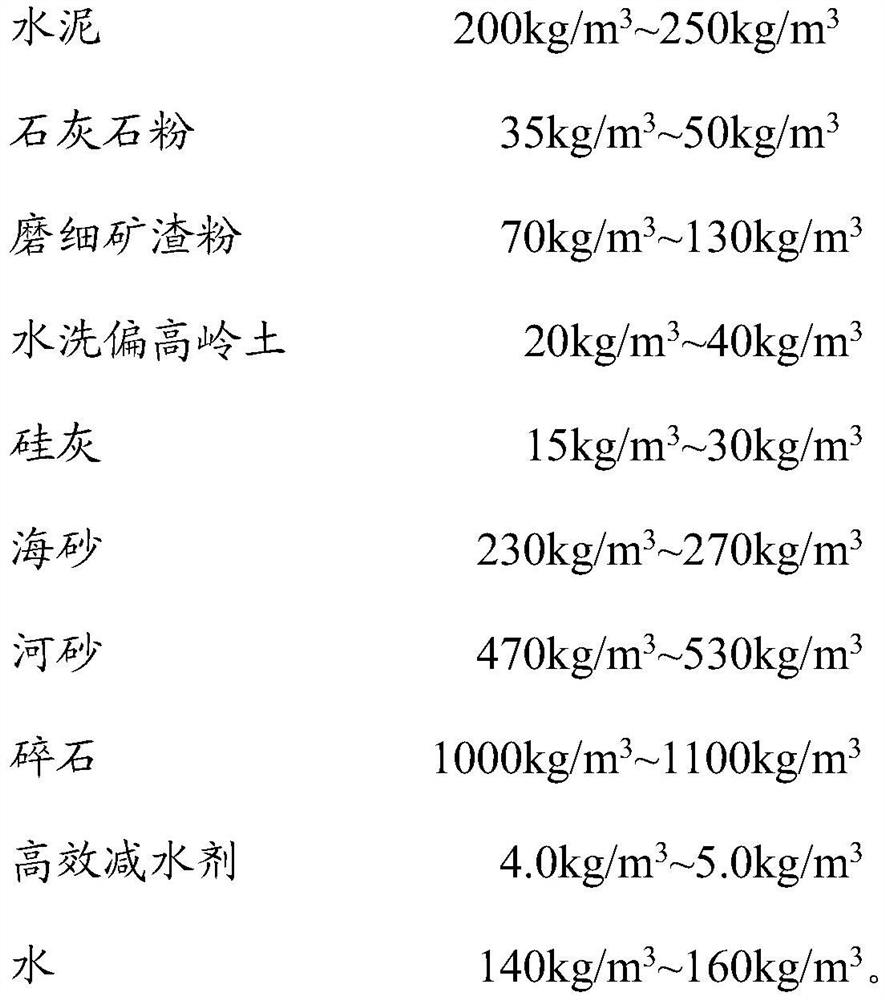

Method used

Image

Examples

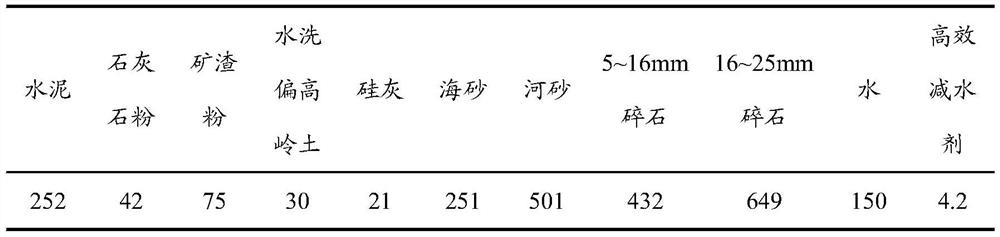

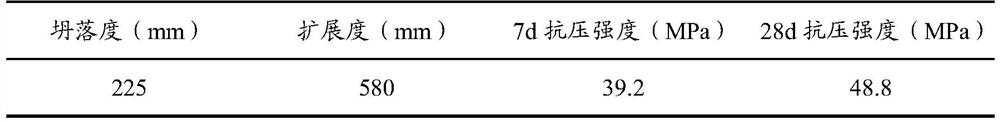

Embodiment 1

[0036] In this embodiment, the cement is P.O42.5 ordinary Portland cement; the limestone powder is 400 mesh, the calcium carbonate content is 99wt%, and the density is 2.70g / cm 3 , the fluidity ratio is 96.9%; the fluidity ratio of slag powder is 120.4%, and the density is 2.95g / cm 3 , the specific surface area is 469kg / m 2 ;Water-washed metakaolin is produced by thermal activation of North Sea kaolin, with an average particle size of 4.02μm and a BET specific surface area of 13.56m 2 / g; SiO in silica fume 2 The content is 95wt%, and the specific surface area is 22437m 2 / kg; the sea sand fineness modulus is 2.60, the chloride ion content is 0.015wt%, and the shell content is 2.8wt%; the river sand fineness modulus is 2.52, and the weight ratio of sea sand to river sand is 1:2; Granite is used as the stone, with continuous gradation of 5mm-16mm and 16mm-25mm. Among them, the weight ratio of 5mm-16mm grading gravel to 16mm-25mm grading gravel is 0.67; Carboxylic acid sup...

Embodiment 2

[0049] In this embodiment, the cement is P.O52.5 ordinary Portland cement; the limestone powder is 600 mesh, the calcium carbonate content is 99wt%, and the density is 2.78g / cm 3 , the fluidity ratio is 100.2%; the fluidity ratio of slag powder is 118.6%, and the density is 2.97g / cm 3 , the specific surface area is 465kg / m 2 ;Water-washed metakaolin is Maoming metakaolin, with an average particle size of 3.88μm and a BET specific surface area of 18.06m 2 / g; SiO in silica fume 2 The content is 93wt%, and the specific surface area is 22356m 2 / kg; sea sand fineness modulus is 2.58, chloride ion content is 0.008wt%, shell content is 2.7wt%; river sand fineness modulus is 3.30, wet sand moisture content is 6wt% ~ 6.5wt%, sea sand The weight ratio to river sand is 1:2; the gravel is continuously graded at 5mm-16mm and 16mm-25mm, and the weight ratio of 5mm-16mm-graded gravel to 16mm-25mm-graded gravel is 0.43; high-efficiency water reducer The polycarboxylate high-efficiency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com