Wedge surface structure for using local large-angle wedge surface to control oblique detonation wave

A large-angle, detonation wave technology, used in machines/engines, jet propulsion devices, gas turbine devices, etc., can solve problems such as increasing the size of the engine, controlling the detonation wave, increasing the resistance, and achieving the effect of maximizing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

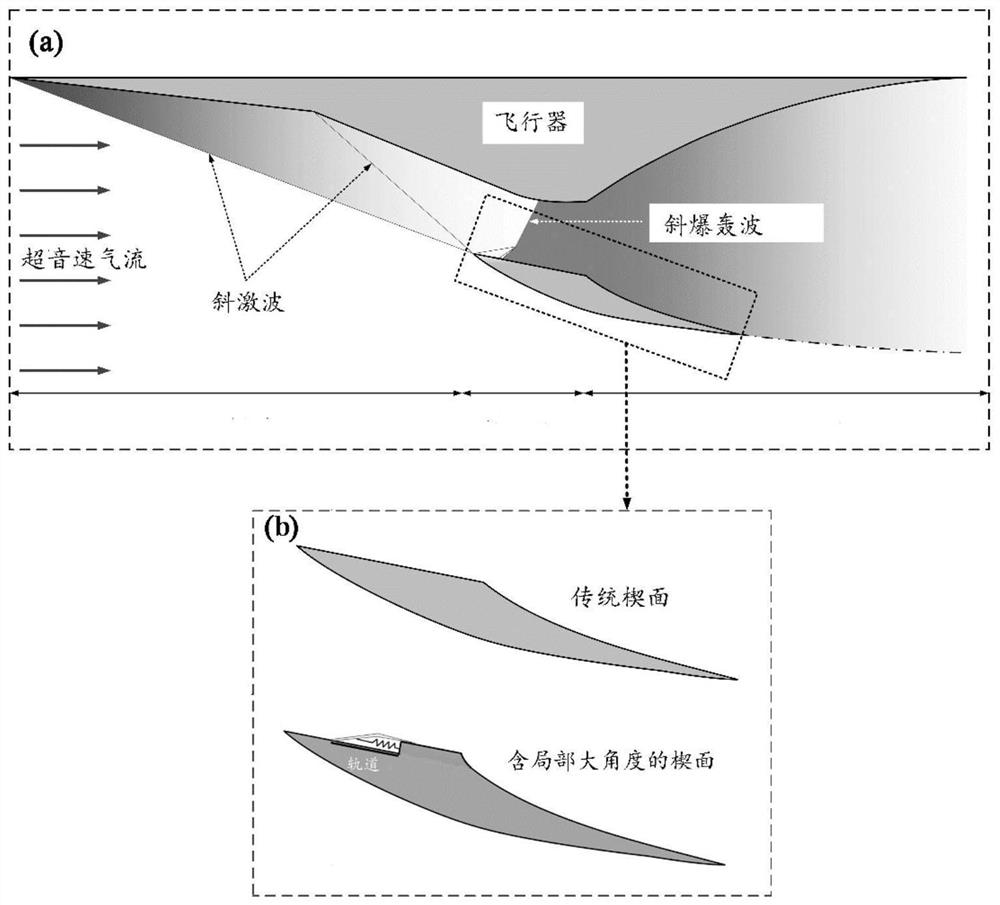

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

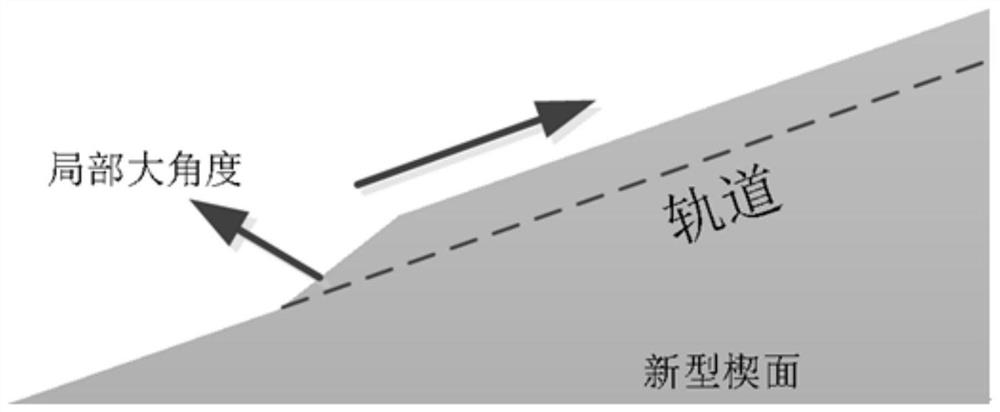

[0019] The present invention provides a wedge surface structure that uses a local large-angle wedge surface to control the oblique detonation wave, which stabilizes the oblique detonation wave at the optimal position through the local large-angle wedge surface angle, and at the same time minimizes resistance and total pressure loss , So as to optimize the thrust performance.

[0020] Such as Figure 2-4 As shown, a wedge surface structure using a local large-angle wedge surface to control oblique detonation waves, the wedge surface structure adds a local large-angle wedge surface to the flat wedge surface. The large-angle wedge surface can provide the oblique shock wave of sufficient intensity to obtain sufficient temperature rise. Under the action of a large local angle, the oblique detonation wave can be continuously stabilized on the local large-angle wedge s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com