Sulfur-tolerant shift method and sulfur-tolerant shift device for multistage adjustment of water-gas ratio

A technology of sulfur-resistant conversion and water-gas ratio, which is applied in the field of coal chemical industry, can solve the problems of reactor damage, large equipment investment, catalyst sintering, etc., and achieve the effects of reducing steam consumption, rich control methods, and good inlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Raw gas composition: H 2 24.2mol%; CO 31.1mol%; CO 2 15.1mol%;CH 4 2.1mol%; N 2 0.2mol%;H 2 O 26.6mol%; H 2 S 0.2mol%; NH 3 0.5 mol%.

[0041] Feed gas temperature: 186°C.

[0042] Sulfur resistant conversion device:

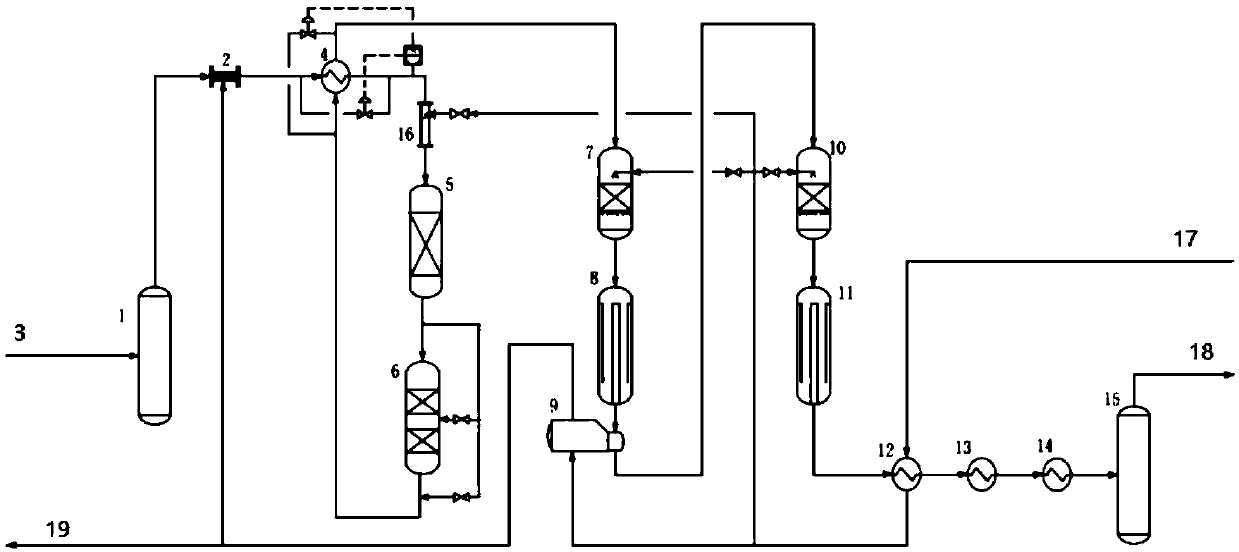

[0043] Raw material gas separator tank 1, steam distribution mixer 2, raw gas heat exchanger 4, spray desuperheater 16, guard bed reactor 5, primary sulfur-resistant shift reactor 6, raw material connected in sequence according to material flow direction Gas heat exchanger 4, desuperheating tower I7, secondary sulfur-resistant shift reactor 8, steam generator 9, desuperheating tower II10, third-stage sulfur-tolerant shift reactor 11, boiler feed water heat exchanger 12, desalinated water heat exchange Device 13, water cooler 14 and gas-liquid separator 15.

[0044] The boiler feed water pipeline is connected to the boiler feed water heat exchanger 12, and the boiler feed water outlet of the boiler feed water heat exchanger 12 is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com