A rotary sieving machine for ore

A sorting machine and ore technology, which is applied in the field of mining machinery and equipment, can solve the problems of limited effect and insufficient filtration, and achieve the effect of thorough filtration and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

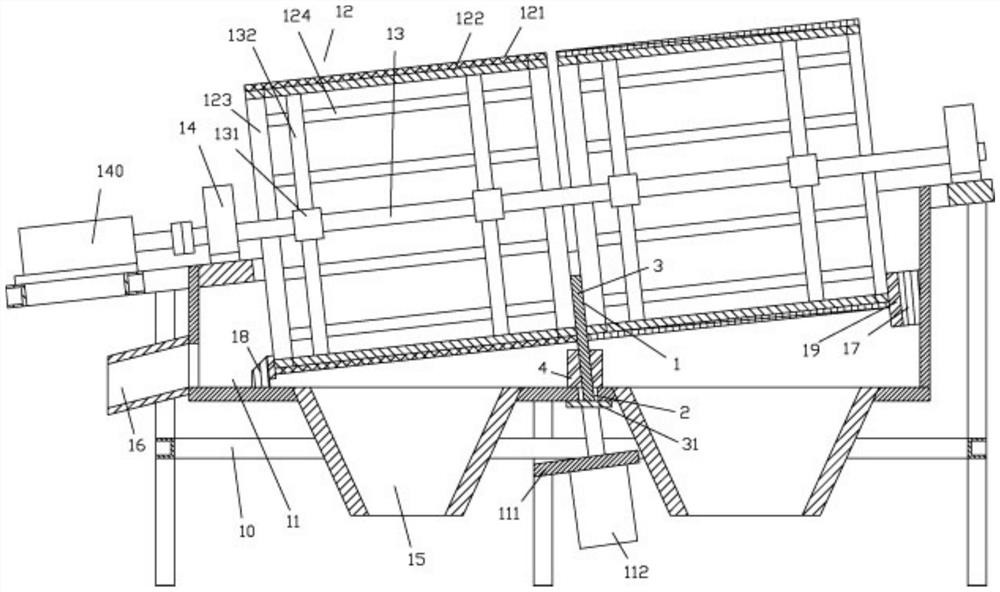

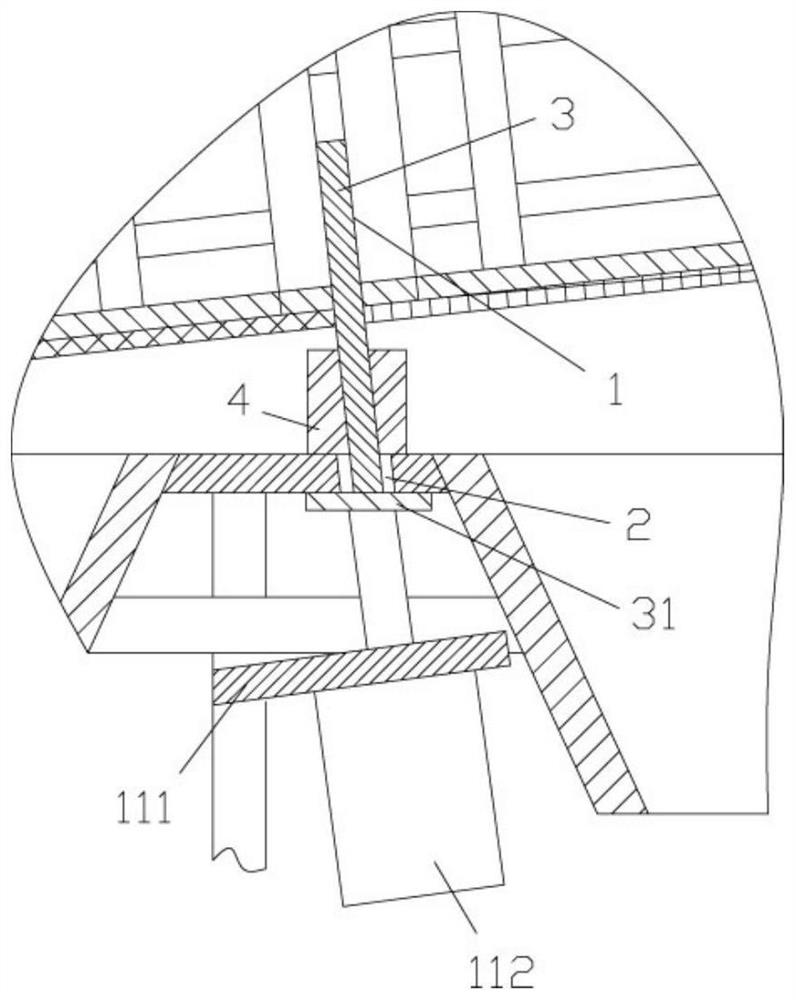

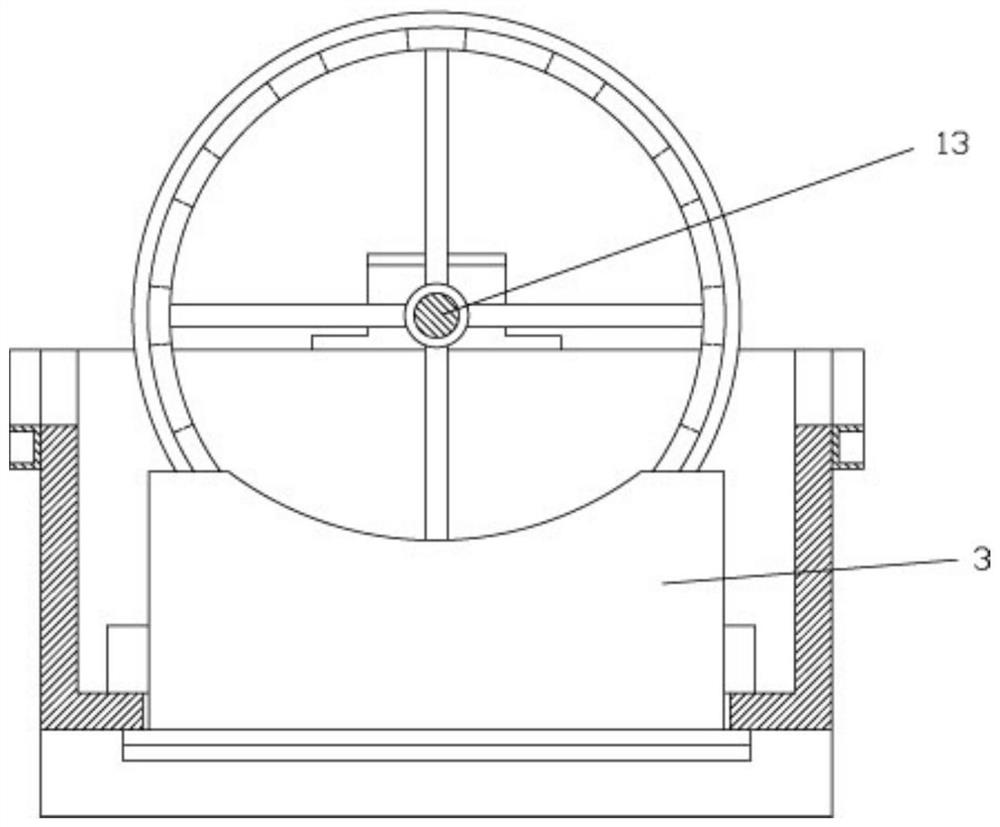

[0021] Examples, see e.g. Figure 1 to Figure 3 As shown, a rotary sieving machine for ore includes a main frame 10, on which a main tank body 11 is installed, and a rolling body 12 arranged obliquely is inserted in the main tank body 11, and the middle part of the rolling body 12 An oblique main shaft 13 is provided, and the two ends of the oblique main shaft 13 are fixed in the inner ring of the bearing seat 14 installed at the front end and the rear end of the main frame 10;

[0022] The rolling element 12 includes at least two filter screen sleeves 121 and two sleeve frames 122, the sleeve frames 122 are inserted into the corresponding filter screen sleeves 121, and the filter screen sleeves 121 are fixed on the sleeve frame 122. On the outer wall, a plurality of support rings 131 are fixed on the inclined main shaft 13, and a plurality of support rods 132 are fixed on the outer wall of the support ring 131, and the support rods 132 are fixed on the inner wall of the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com